Piezoelectric actuator

一种压电致动器、压电体的技术,应用在压电/电致伸缩换能器、传感器、电气元件等方向,能够解决大电阻、外壳异常声音、音圈燃烧等问题,达到缓和碰撞、高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-9

[0086] For evaluating the effect of the present invention, evaluate the present invention according to the following examples 1-9 and comparative examples 1-4

[0087] Invention of properties of piezoelectric actuators. The evaluation items are as follows.

[0088] (Evaluation 1) Measurement of resonance frequency: The resonance frequency was measured when an AC voltage of 1 V was applied.

[0089] (Evaluation 2) Maximum amplitude of vibration velocity: When an AC voltage of 1 V was applied, the maximum amplitude of vibration velocity at the resonance frequency was measured.

[0090] (Evaluation 3) The average amplitude of the vibration velocity: eg Figure 10 As shown, the amplitudes of the vibration velocities were measured at 20 measurement points (indicated by 1-20 in the figure) equally spaced along the longitudinal direction of the piezoelectric element 1, and their average values were calculated.

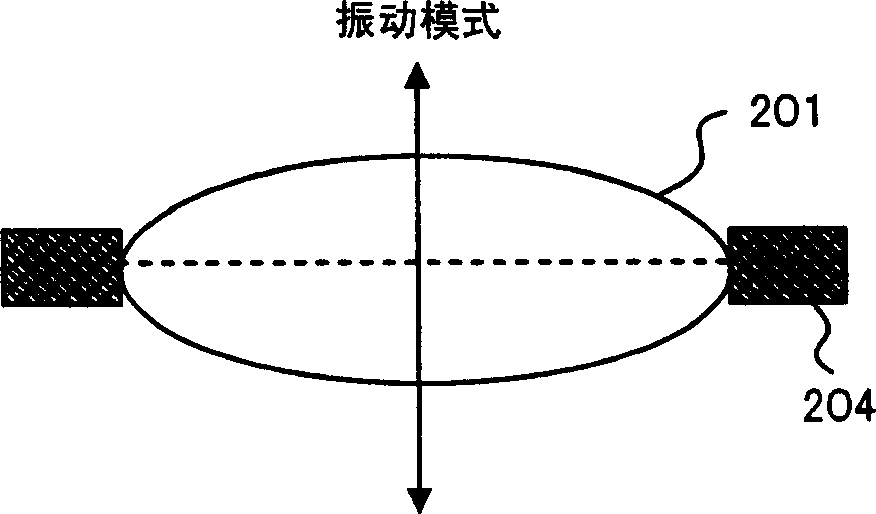

[0091] (Evaluation 4) Vibration mode: such as Figure 11A and 11B...

example 1

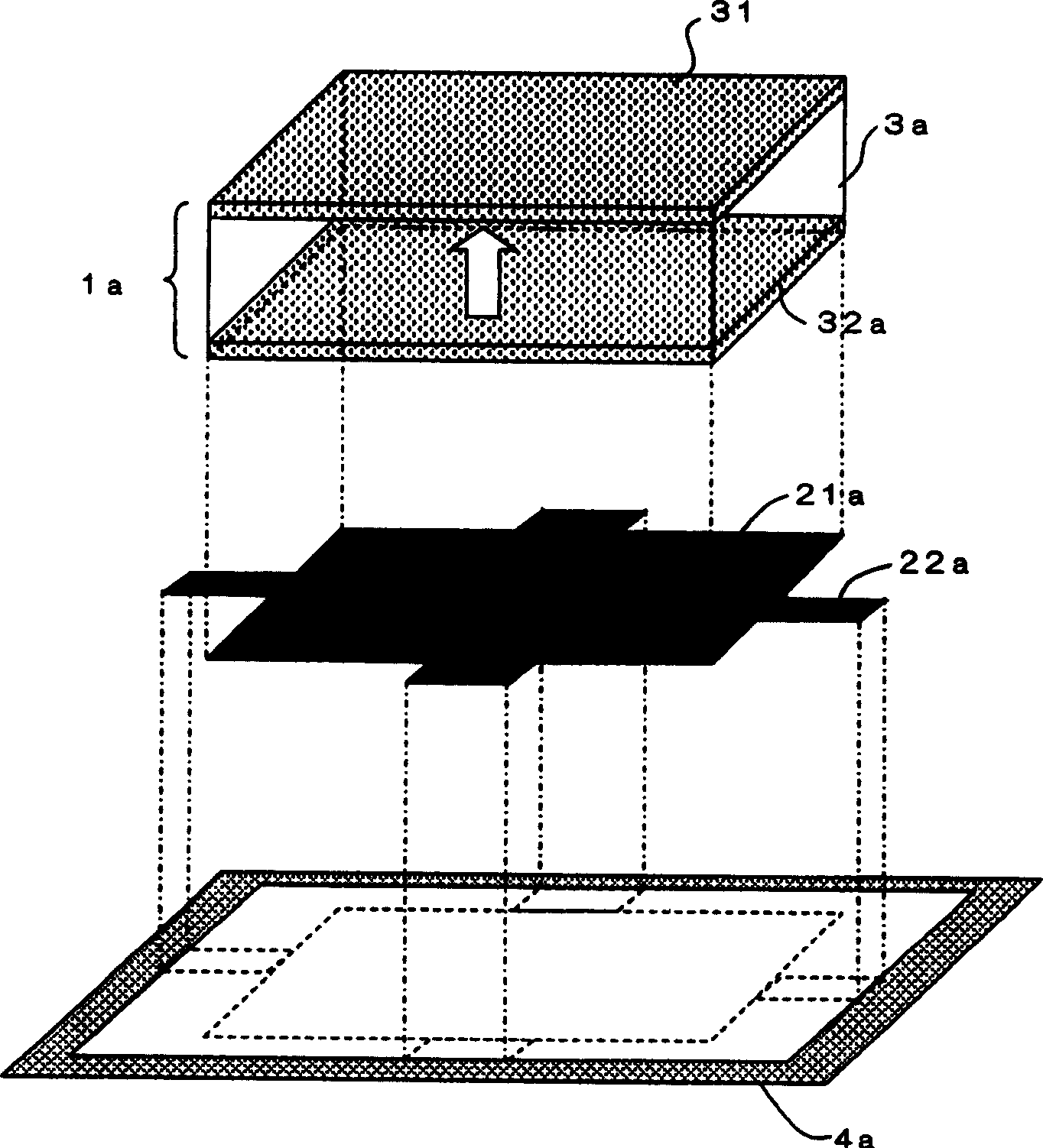

[0096] make Figure 12A , 12B The piezoelectric actuator shown. Figure 12A A top plan view showing the base, beam members, and support members. The unit of each value in the figure is millimeter. Figure 12B The exploded simultaneous views of the piezoelectric element are shown in sequence. The piezoelectric actuator of Example 1 has a piezoelectric element 101a, a base 121a, a support member 104a, and a beam member 122a. The piezoelectric member 101a is bonded to the base 121a using epoxy-based glue, and the base 121a is connected to the support member 104a by four beam members 122a.

[0097] Such as Figure 12B As shown, the piezoelectric element 101a is a single-layer piezoelectric element composed of an upper insulating layer 133a, an upper electrode layer 131a, a piezoelectric body 103a, a lower electrode layer 132a, and a lower insulating layer 133a'. The upper insulating layer 133 a and the lower insulating layer 133 a ′ have a length of 10 mm, a width of 10 mm, ...

example 2

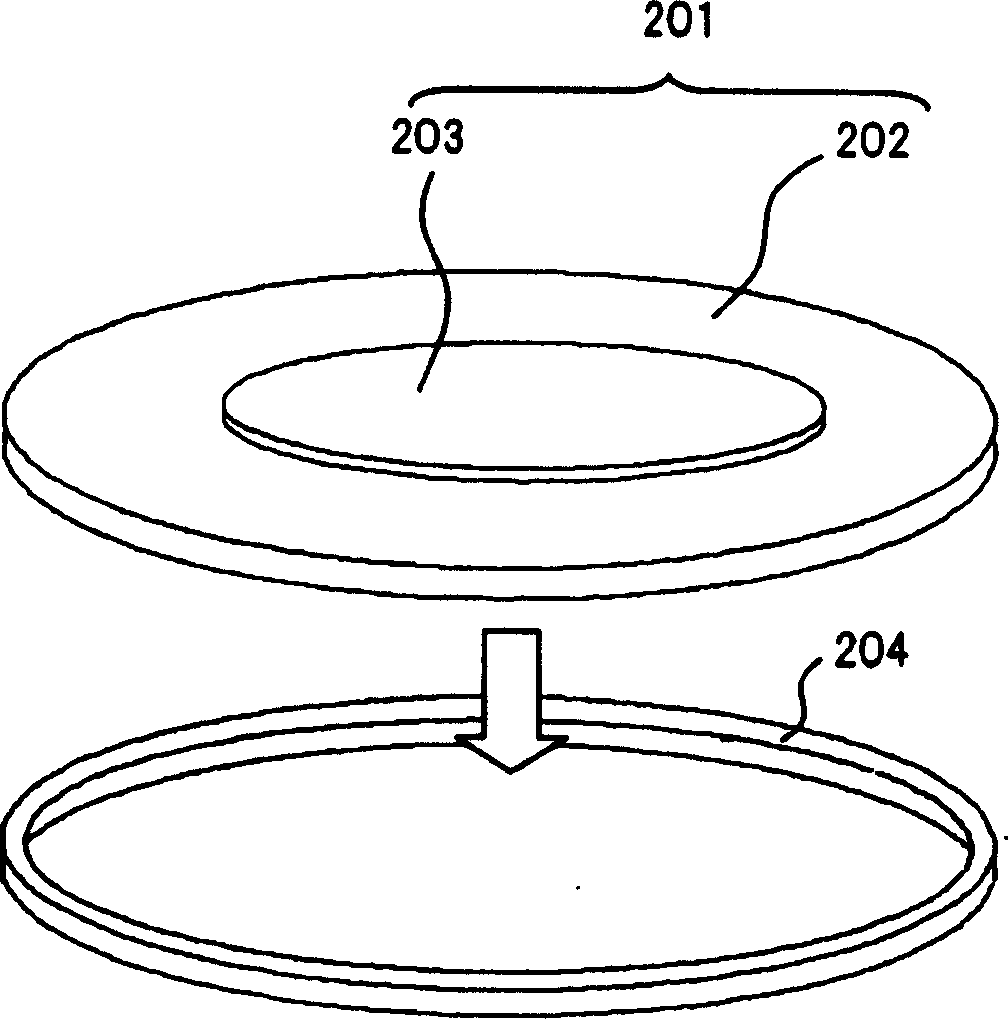

[0106] In Example 2, the number of beam members attached to the base was changed from four in Example 1 to two in order to confirm the degree of reduction in resonance frequency. Such as Figure 14 As shown, the conditions are the same as in Example 1 except for the number of beam members. The piezoelectric actuator is circular with a diameter of 16 mm and a thickness of 0.45 mm. The unit of each value in the figure is millimeter. The piezoelectric actuator gives a reciprocating vibration mode, the resonance frequency is 498HZ, the maximum amplitude of the vibration velocity is 172mm / s, and the maximum vibration velocity ratio is 0.86.

[0107] It was confirmed from a comparison between Example 1 and Example 2 that by changing the number of beam members, the resonance frequency can be lowered without causing a large change in vibration mode or vibration velocity amplitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com