Concentrated sweet potato juice and production thereof

A technology of sweet potato and clear juice, which is applied in the field of fruit deep processing, and can solve the problems of affecting sales image, precipitation and browning of taste, and insufficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

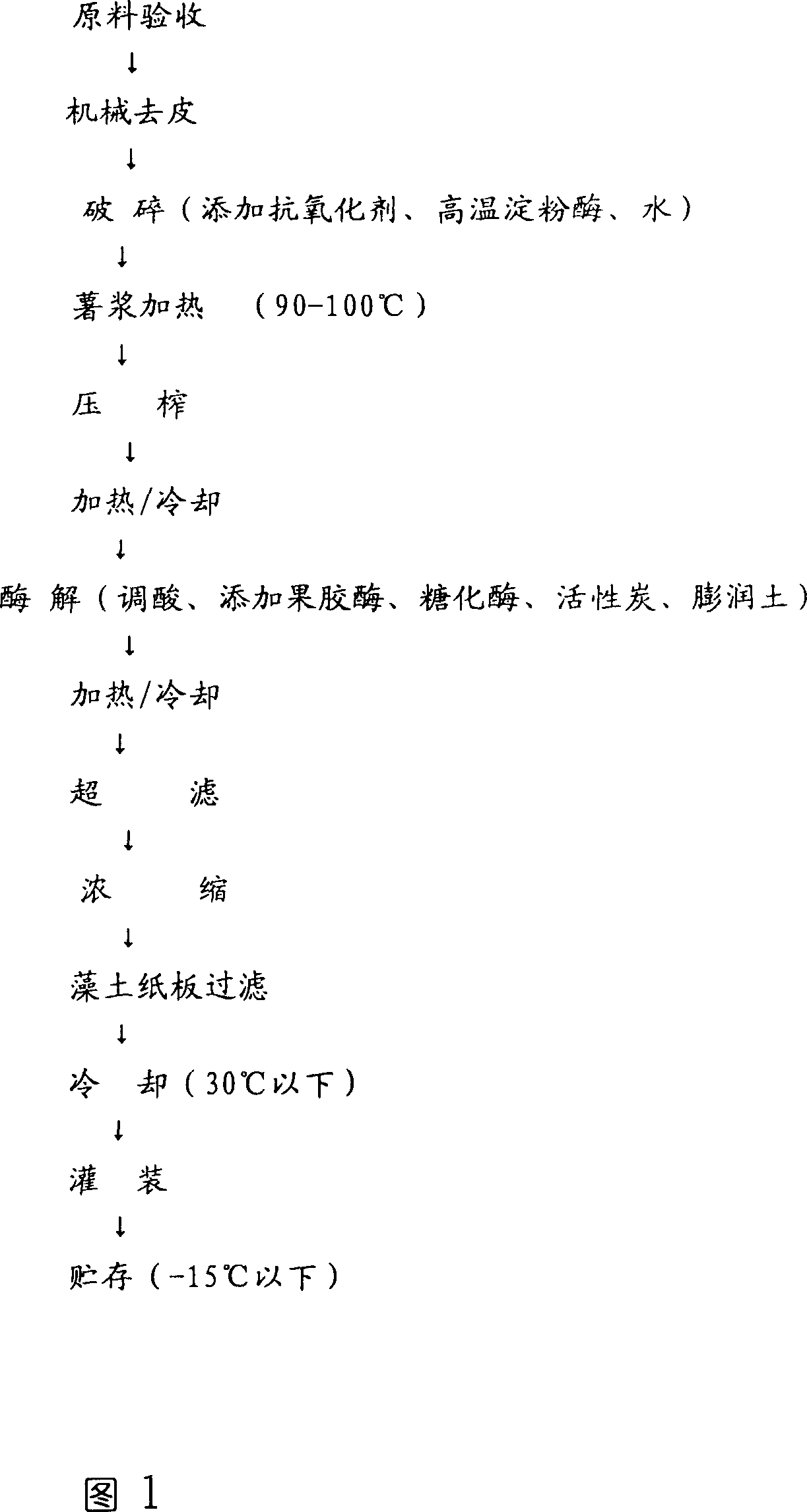

Method used

Image

Examples

Embodiment 1

[0024] 1. Mechanical peeling of raw materials: ensure that the peeling rate reaches more than 60%.

[0025] 2. Broken:

[0026] 2-1. When crushing sweet potatoes, demineralized water above 50°C should be added. Water and potato pulp should be added in a ratio of 0.5:1, and the crushed particle size should be controlled at 2-5 mm;

[0027] 2-2. Add vitamin C at a ratio of 0.02% of sweet potato puree while crushing raw materials. Vitamin C is diluted into an aqueous solution before adding, and directly added to the fruit pulp while crushing raw materials through a metering pump;

[0028] 2-3. Add amylase in the proportion of 0.25% sweet potato clear juice while crushing raw materials, and dilute to 5-20% enzyme preparation solution before adding amylase.

[0029] 3. Potato pulp heating: heat the potato pulp to above 85°C, keep it warm in the storage tank, and control it within 2 hours.

[0030] 4. Squeeze: Squeeze the potato pulp through a press.

[0031] 5. Heating / cooling: ...

Embodiment 2

[0059] 1. Mechanical peeling of raw materials: ensure that the peeling rate reaches more than 60%.

[0060] 2. Broken:

[0061] 2-1. When crushing sweet potatoes, demineralized water above 50°C should be added, and water and potato pulp should be added in a ratio of 3:1, and the crushed particle size should be controlled at 2-5 mm;

[0062] 2-2. Add vitamin C at a ratio of 0.07% of sweet potato puree while crushing raw materials. Vitamin C is diluted into an aqueous solution before adding, and directly added to the fruit pulp while crushing raw materials through a metering pump;

[0063] 2-3. Add amylase in the proportion of 0.03% sweet potato clear juice while crushing raw materials, and dilute to 5-20% enzyme preparation solution before adding amylase.

[0064] 3. Potato pulp heating: heat the potato pulp to above 95°C, keep it warm in the storage tank, and control it within 0.5 hours.

[0065] 4. Squeeze: Squeeze the sweet potato pulp through a press.

[0066] 5, heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com