Synthesis of degradable aromatic/fatty copolymer ester by in-situ ester

A kind of oligomeric lactic acid and degradability technology, applied in the field of preparation of aromatic/aliphatic copolyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

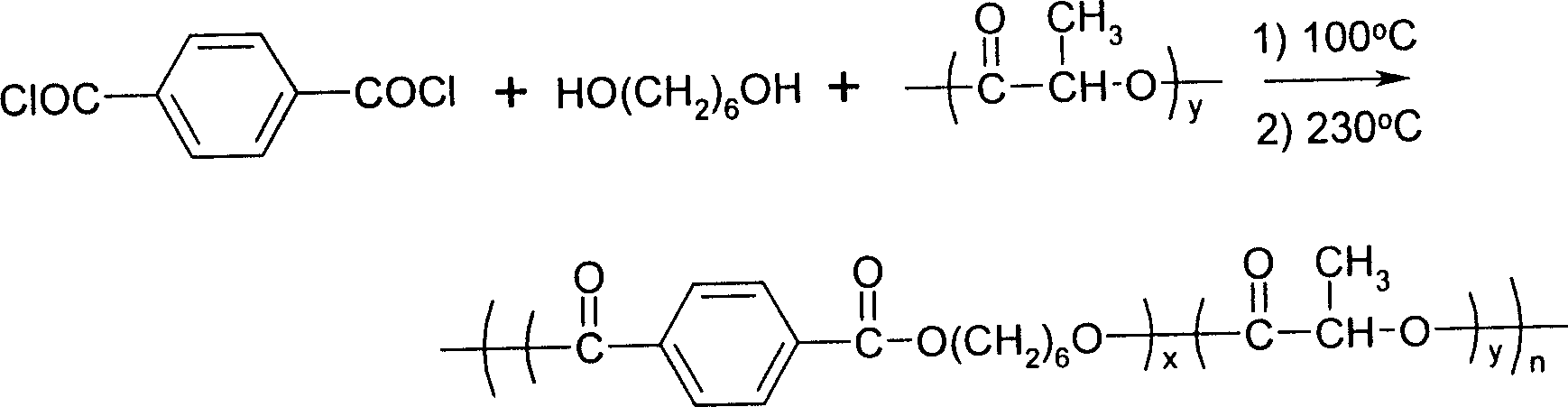

Method used

Image

Examples

Embodiment 1

[0035] 1.0mol terephthaloyl chloride (TPC), 1.0mol ω-hydroxy oligoethylene glycol (PEG) and 0.3mol D, L-oligomeric lactic acid solution co-condensation, diphenyl ether as solvent, according to the conventional process, maintained at 100 ° C 12h, maintained at 230°C for 4h, synthesized TPC / PEG / PLA copolyester.

Embodiment 2

[0037] 1.0mol isophthaloyl chloride (IPC), 1.0mol aliphatic dihydric alcohol (ADO) and 0.8mol D, L-oligomeric lactic acid solution polycondensation, synthetic TPC / ADO / PLA copolyester, reaction condition is the same as embodiment 1 .

Embodiment 3

[0039] 1.0mol terephthaloyl chloride (TPC), 1.0mol aliphatic diol (ADO) and 0.5mol D, L-oligomeric lactic acid bulk melt co-condensation, according to the conventional process, 100 ° C for 12 hours, 230 ° C for 4 hours, vacuum (about 10mbar) at 230°C for 4h to synthesize TPC / ADO / PLA copolyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com