Box-depositing dock light quantization

A lightweight, caisson-type technology, applied in the field of port engineering and water conservancy engineering, can solve the problems of affecting the surrounding environment and costs, and achieve the effect of reducing workload, saving cost, and reducing secondary environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

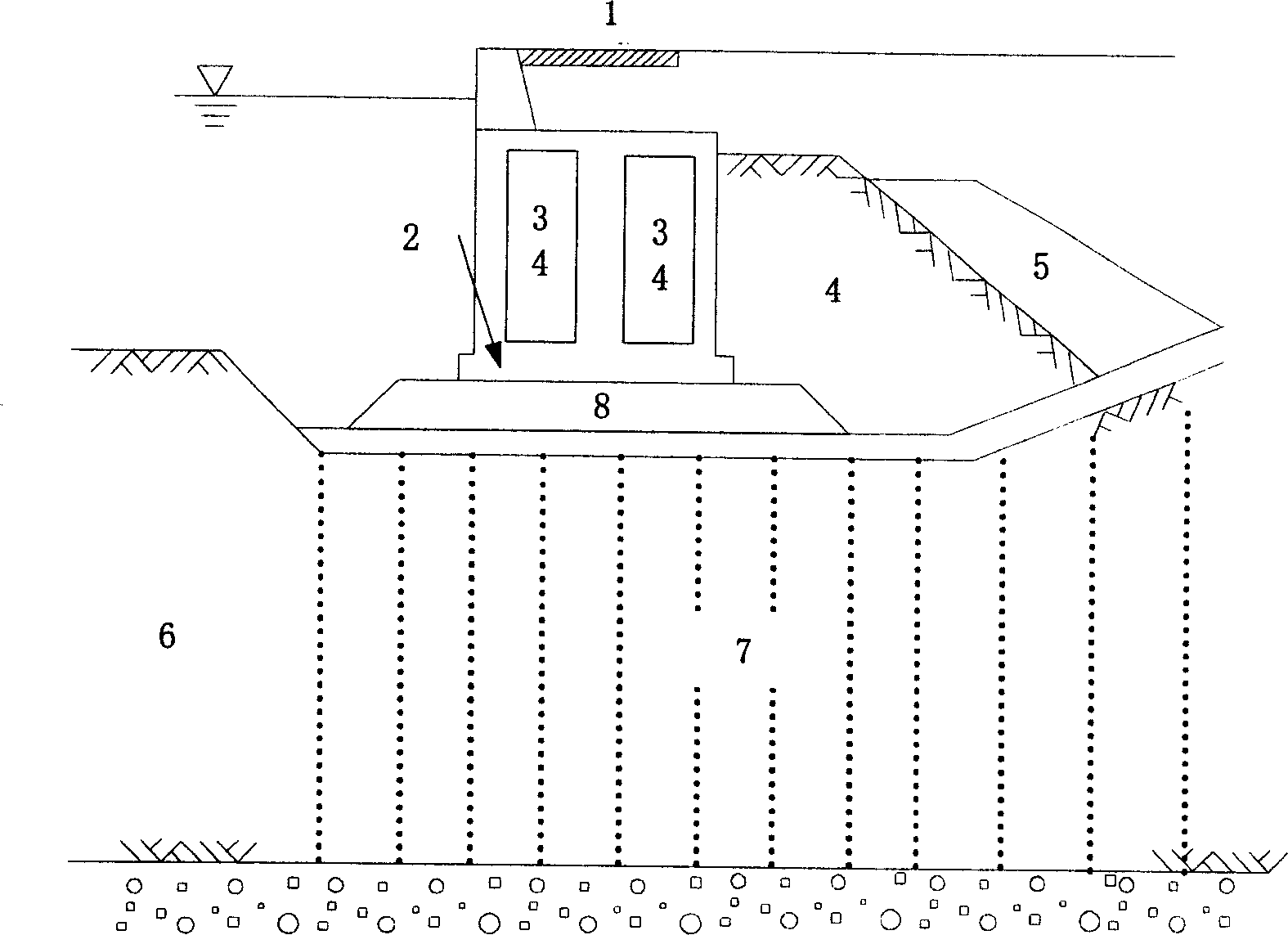

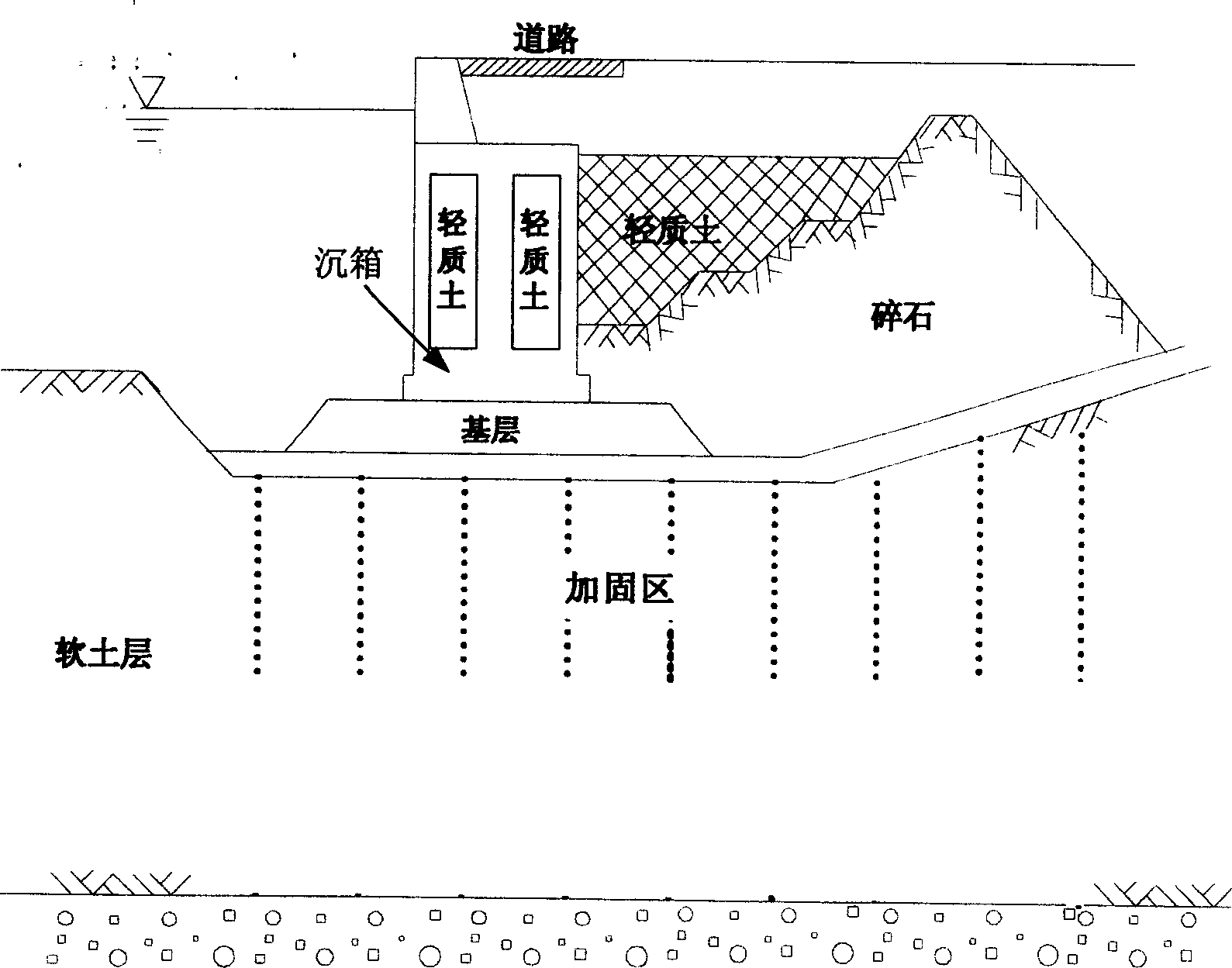

[0024] The key to the implementation of the caisson wharf lightweight method is to replace the stones backfilled after the caisson and the sand filled in the caisson cavity with light soil. Taking the construction of a certain wharf as an example to describe the lightweight chemical method of the caisson type wharf.

[0025] 1). The silt in the caisson 2 and the backfill 4 of the caisson is sucked out at the berth of the wharf;

[0026] 2). Send the suctioned silt to the rear site to add cement and plastic foam to stir into lightweight soil materials; the foam agent materials are lightweight agents such as plastic foam and waste tires. The weight of light soil for underwater filling shall not be less than 1.0g / cm 3 .

[0027] 3). Level the base layer 8 at the bottom of the caisson 2, float and install the caisson 2;

[0028] 4). After the caisson 2 is installed, throw and fill the light soil behind the caisson 2, and fill the light soil formed by stirring in the empty stoma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com