Application of poplar wood powder liquefaction product as sustainable asphalt modifier, sustainable modified asphalt and preparation method

A technology of liquefied product and modified asphalt, applied in building structures, building components, building insulation materials, etc., can solve problems such as hindering an environment-friendly society, environmental pollution, restricting the long-term development of road materials, etc., to reduce the secondary environment. Pollution, improving liquefaction rate, and the effect of being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

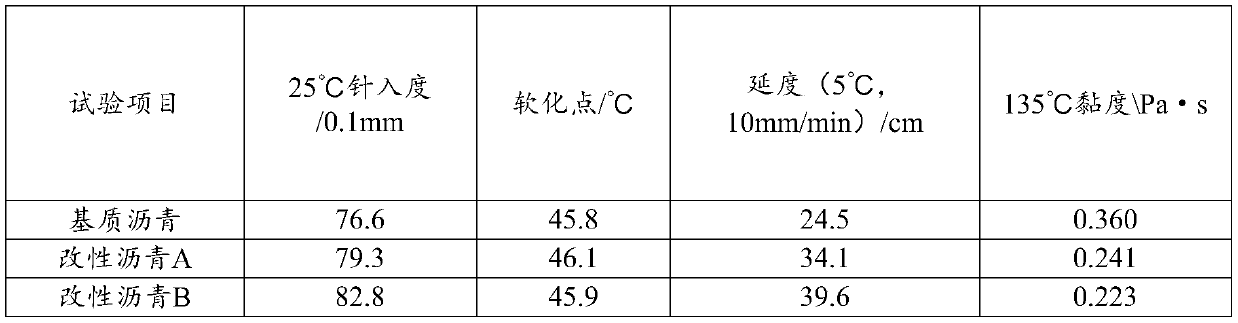

Examples

preparation example Construction

[0022] (2) the preparation method of above-mentioned poplar wood powder liquefaction product, comprises the following steps:

[0023] Step 1, further pulverize the poplar wood powder, pass through a 60-mesh sieve, dry to constant weight, cool, and set aside;

[0024] Step 2, mix the pulverized poplar wood powder, liquefaction agent and catalyst into the reaction kettle, feed nitrogen into the reaction kettle to discharge the air in the reaction kettle, carry out the liquefaction reaction at a certain temperature and time, and the reaction ends Finally, the gas in the reactor is discharged, and the liquefied product is cooled to room temperature to obtain a sustainable asphalt modifier.

[0025] In step 1, the maximum particle size of the wood powder is 60 mesh.

[0026] In step 1, the drying temperature is 105° C., and the drying time is 24 hours.

[0027] In step 2, the initial pressure of the reactor is 3-4 MPa.

[0028] In step 2, the temperature of the liquefaction reac...

Embodiment 1

[0036] A preparation method of sustainable asphalt modifier, comprising the following steps:

[0037] Step 1: Use a micro-plant pulverizer to further pulverize the poplar wood powder, pass through a 60-mesh sieve, place the poplar wood powder that has passed through the sieve in a drying oven at 105°C for 24 hours, cool to room temperature, and set aside.

[0038] Step 2, mix 10g poplar wood powder, 25g liquefaction agent (the mass ratio of p-hydroxyphenylethyl alcohol, polyethylene glycol 400 and glycerol in the liquefaction agent is 1:5:4) and 2g p-toluenesulfonic acid and add To the reactor, open the vent valve and exhaust valve of the reactor at the same time, and continue to feed nitrogen for 1min to remove the air in the reactor. Close the vent valve, and continue to fill with nitrogen until the pressure in the reactor reaches 4MPa, then close the vent valve. Start the reactor, and liquefy at 180°C for 90 minutes. After the reaction is complete, discharge the gas in the...

Embodiment 2

[0042] A preparation method of sustainable asphalt modifier, comprising the following steps:

[0043] Step 1: Use a micro-plant pulverizer to further pulverize the poplar wood powder, pass through a 60-mesh sieve, place the poplar wood powder that has passed through the sieve in a drying oven at 105°C for 24 hours, cool to room temperature, and set aside.

[0044] Step 2, after mixing 10g poplar wood powder, 30g liquefaction agent (the mass ratio of p-hydroxyphenylethyl alcohol, polyethylene glycol 400 and glycerol in the liquefaction agent is 1:5:4) and 2.1g p-toluenesulfonic acid Add it into the reaction kettle, open the ventilation valve and exhaust valve of the reaction kettle at the same time, and continue to feed nitrogen for 1min to remove the air in the reaction kettle. Close the exhaust valve, and continue to fill with nitrogen until the pressure in the reactor reaches 3.5MPa and then close the vent valve. Start the reactor, and liquefy at 160°C for 120 minutes. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com