Method and device for power braking with a fluid-operated liquid metal current switch

A liquid metal, current switch technology, used in electrical switches, circuits, electrical components, etc., to achieve fast response time, good reliability, and a small amount of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

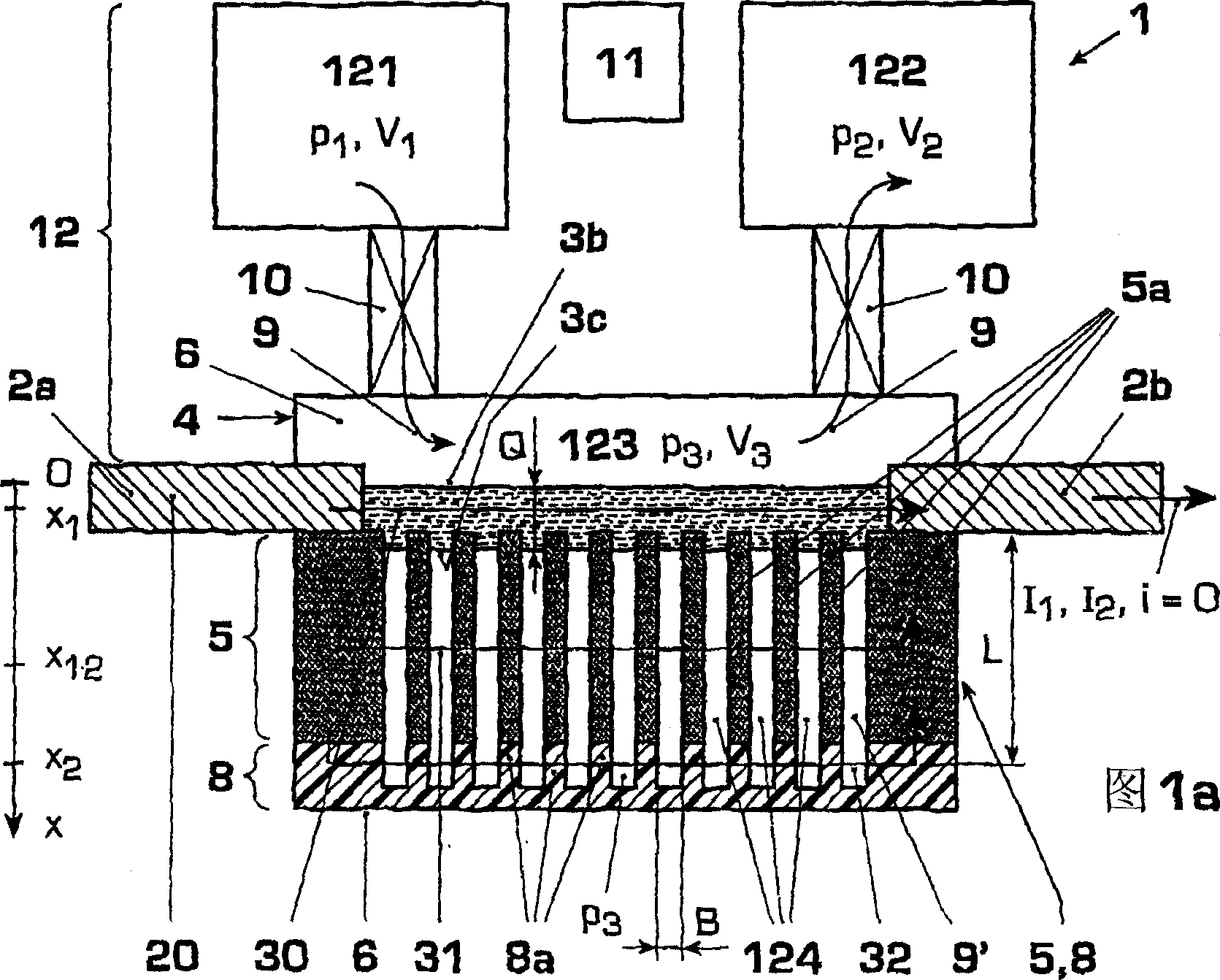

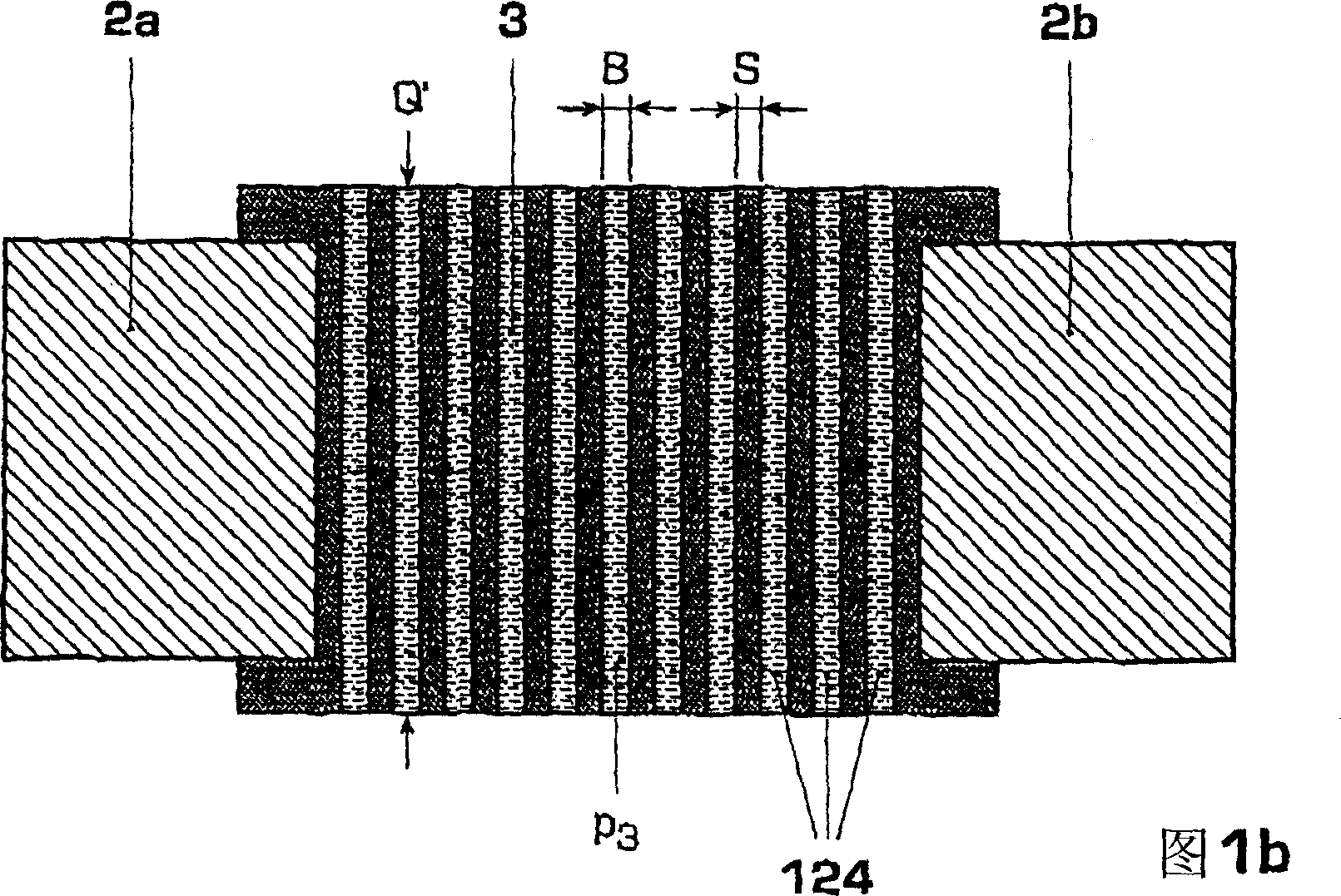

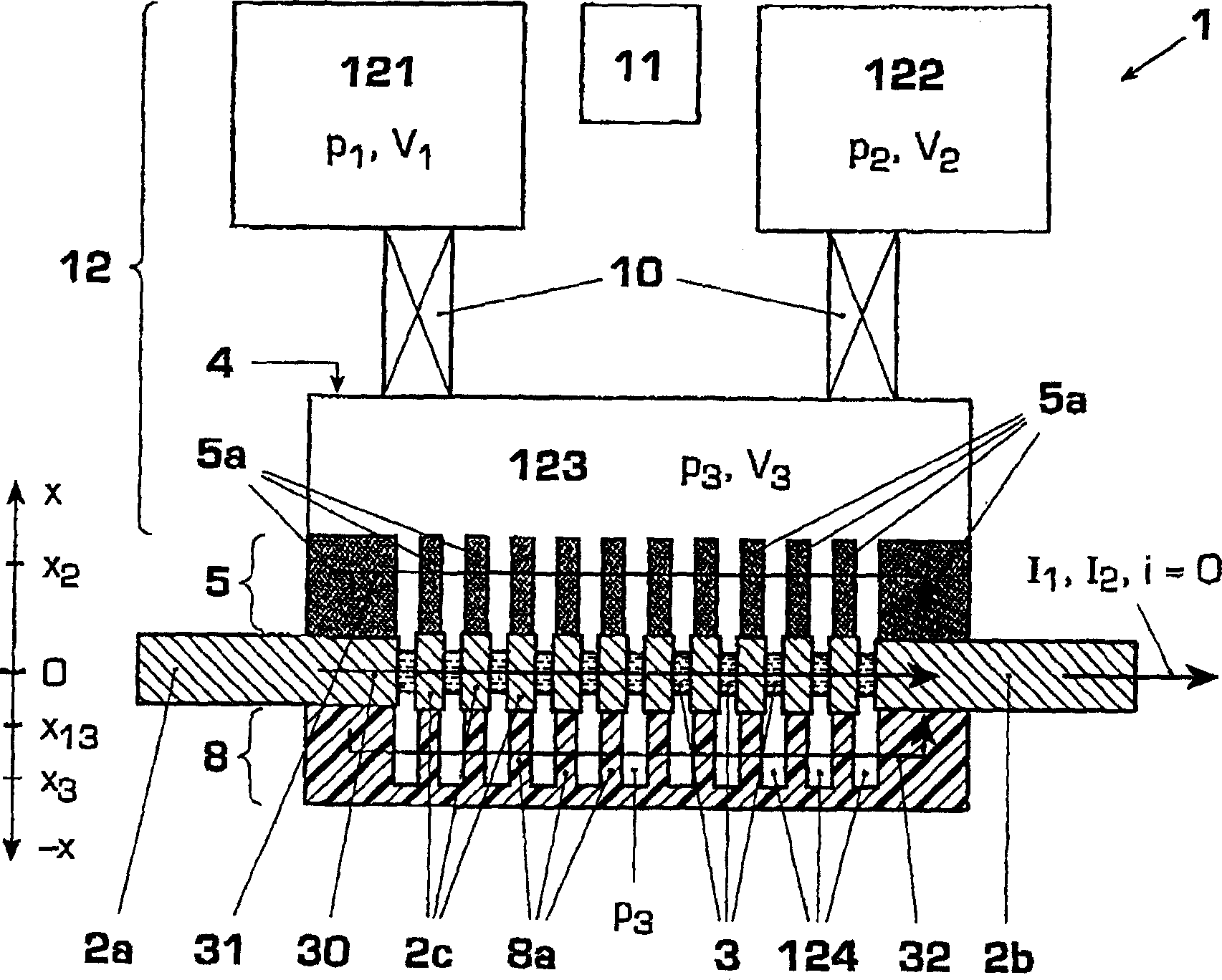

[0027] Figures 1a and 1b show an embodiment of a current switch 1 of the liquid metal type, in particular a current limiter or circuit breaker 1 of the liquid metal type, in cross-section and plan view. The current switch 1 comprises solid metal electrodes 2 a , 2 b for connection to a current source 20 and a container 4 of liquid metal 3 . The container 4 has a bottom 6 of insulating material and a cover 6 , between which a dielectric 5 , 8 , 9 and at least one channel 3 a for the liquid metal 3 are arranged.

[0028] According to the invention, the power switch 1 has a dielectric fluid drive 12 with a control device 11, in which the working fluid 9 operates at a predeterminable drive pressure P 1 , P 2 Act directly on a front side surface 3b of the liquid metal 3 and move the liquid metal body 3 from a first position X 1 Move to a second position X 12 , X 2 middle. in the first position X 1 , the liquid metal 3 is at least partly in the operating current I 1 In the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com