Back incident type quartz reflective polarizing beam split grating of 632.8 nano wave length

A reflective polarization, beam splitting grating technology, applied in the direction of diffraction grating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

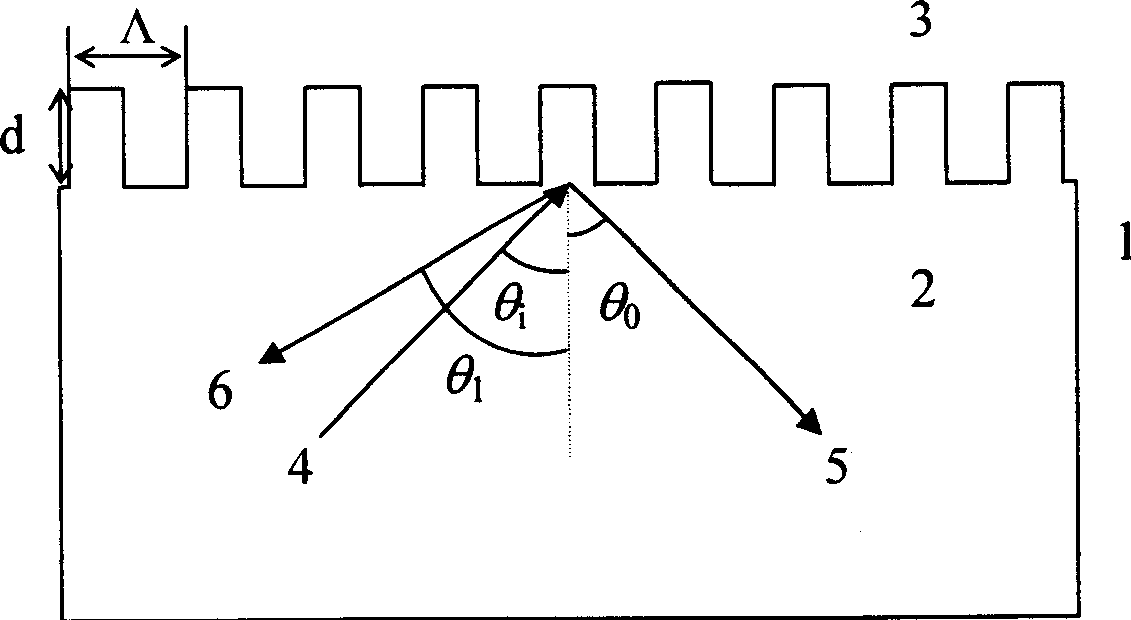

[0020] A high-density rectangular polarizing beam splitter grating is fabricated by micro-optic technology. First, a metal chromium film is deposited on a dry and clean fused silica substrate, and a layer of positive photoresist is uniformly coated on the chromium film (Shipley, S1818, USA ). The grating is then recorded using a holographic recording method, see Image 6 , using He-Cd laser 7 (wavelength 0.441 μm) as the recording light source. When recording the holographic grating, the shutter 8 is opened, and the narrow beam emitted from the laser is divided into two narrow beams by the beam splitter 9 . After one beam passes through the reflector 10 , it passes through the beam expander 14 and the lens 16 to form a wide plane wave; after the other beam passes through the reflector 11 , it forms a wide plane wave through the beam expander 15 and the lens 17 . After the two beams of plane waves pass through the mirrors 12 and 13 respectively, they form an interference fiel...

PUM

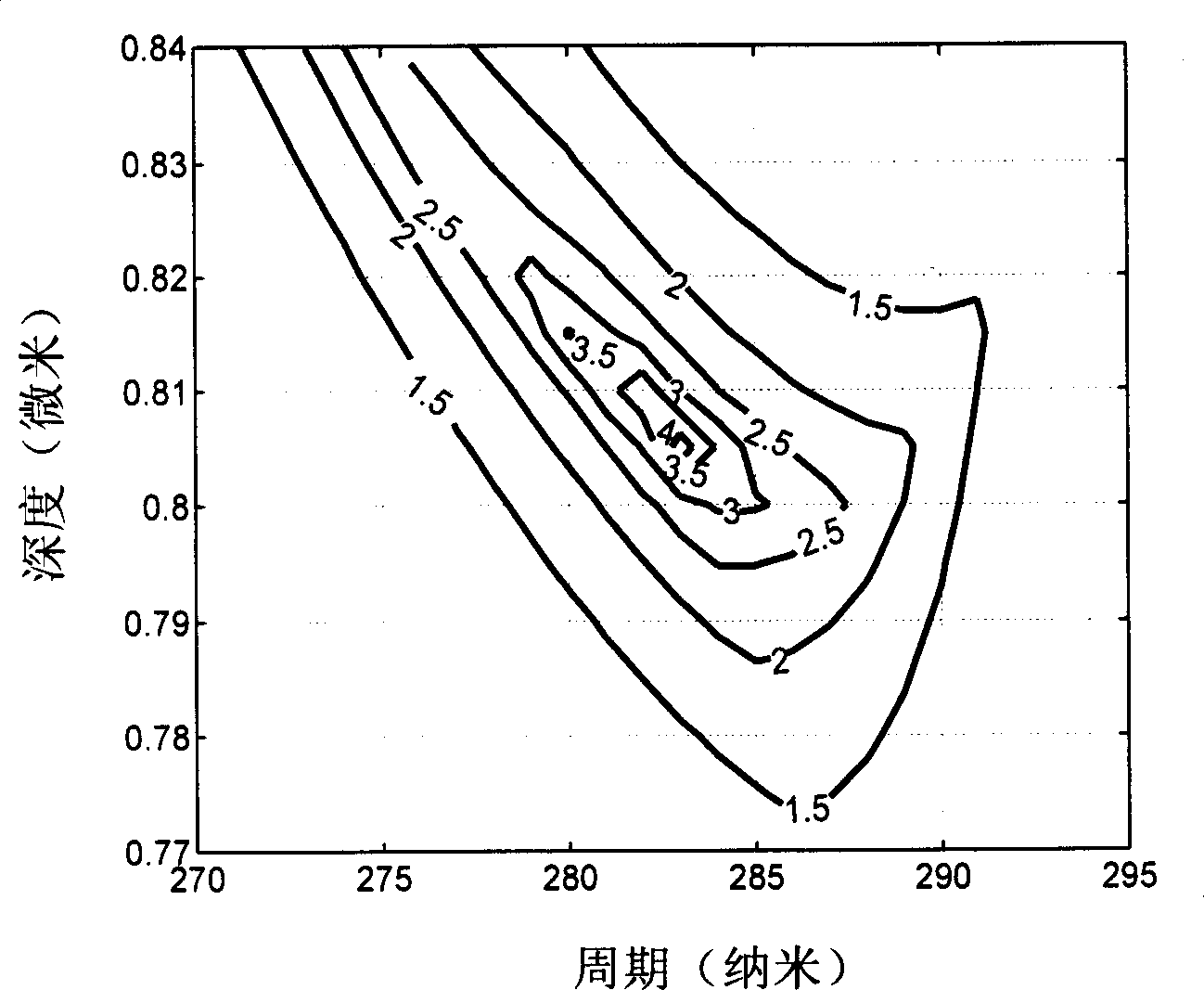

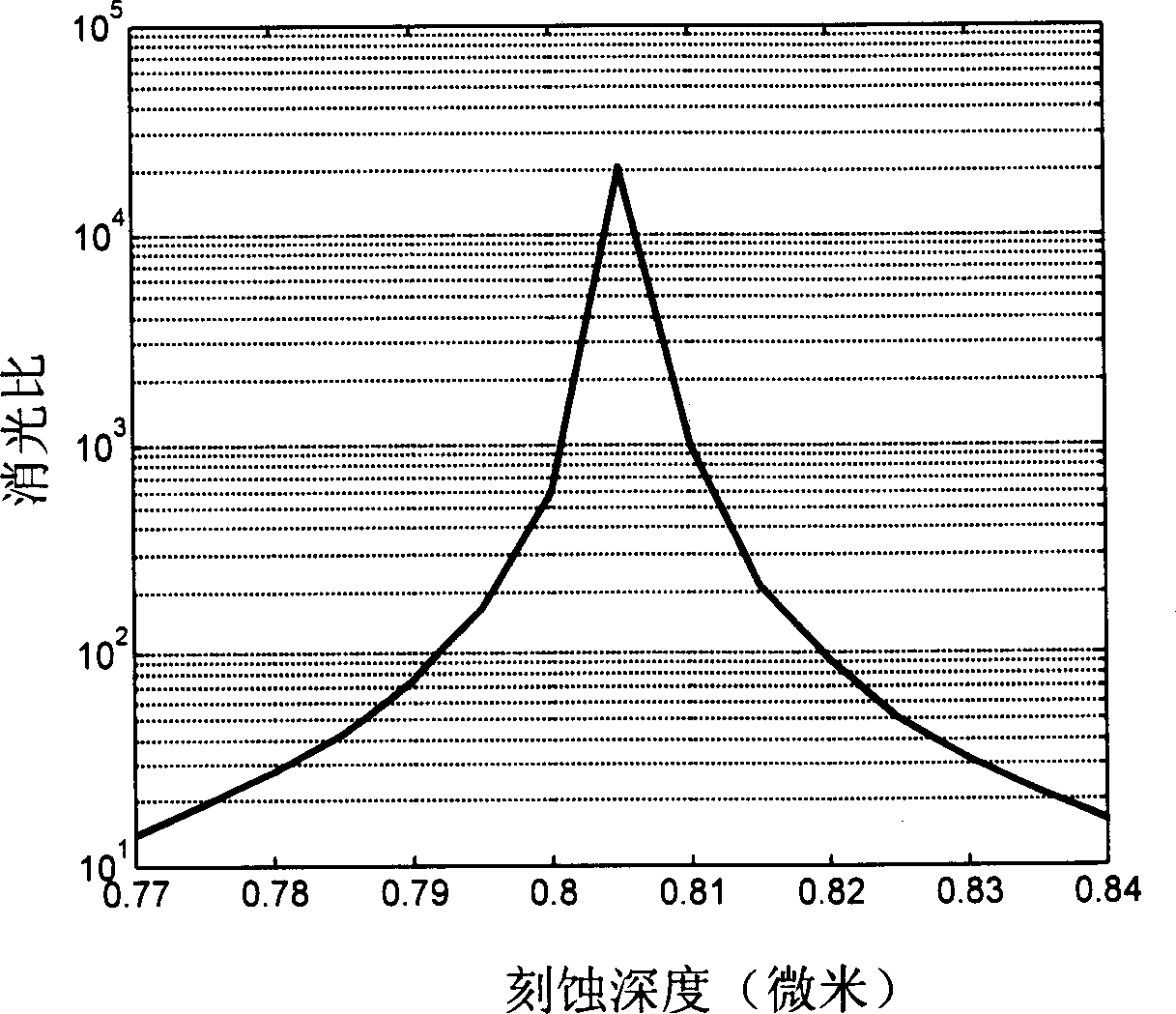

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Cycle | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com