Lamp tube with shade lamp and its producing method

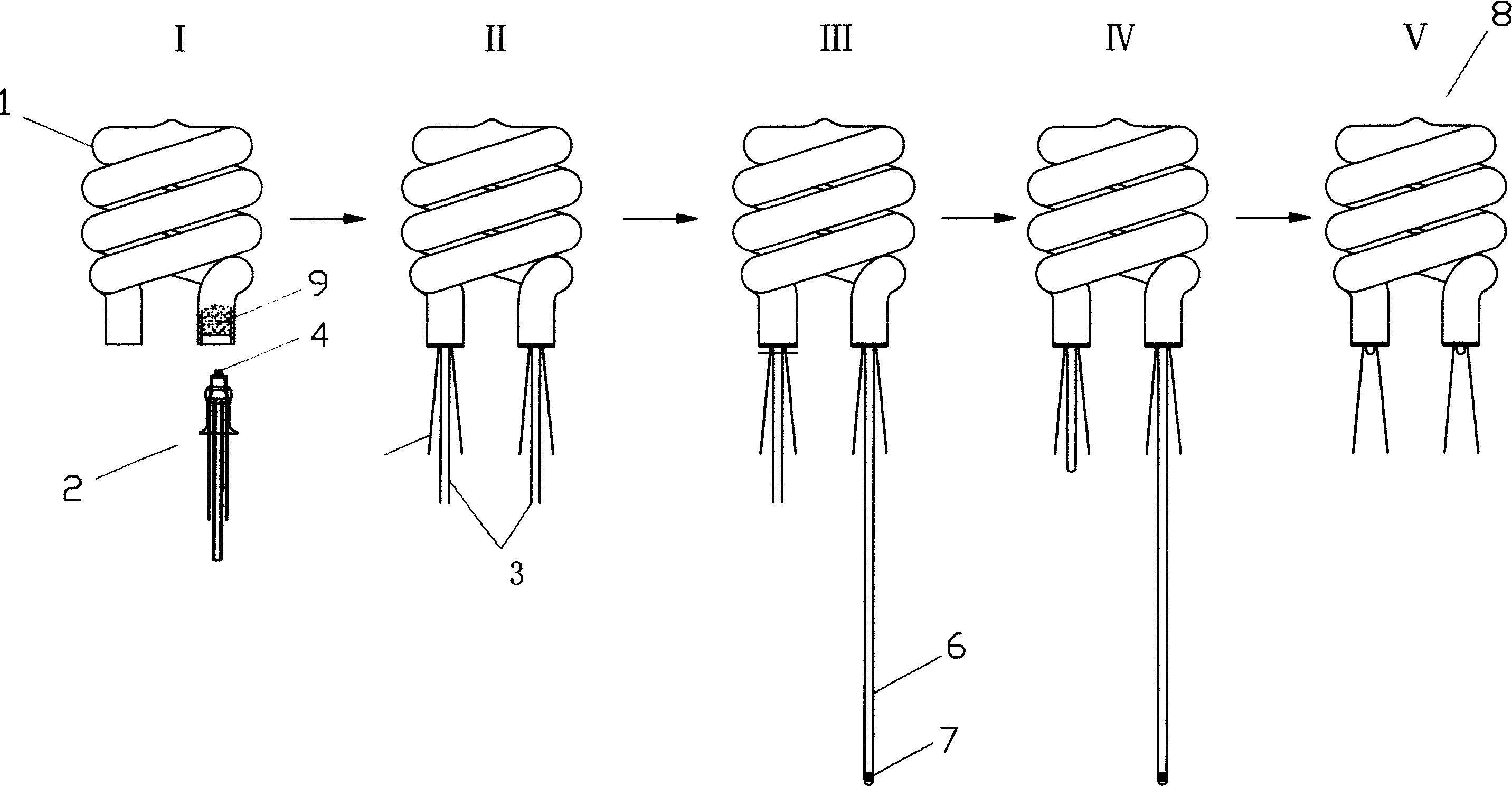

A technology for lamp tubes and cover lamps, which is applied in the manufacturing process of compact fluorescent tubes to achieve the effects of simple operation, improved luminous flux maintenance rate, and optimal saturated vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

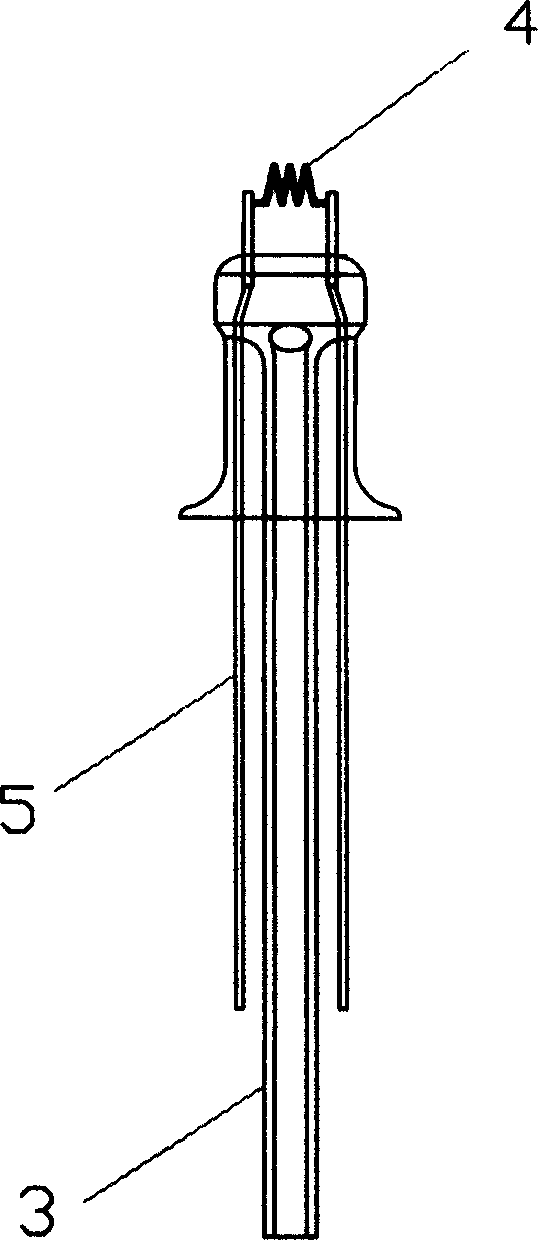

Embodiment 1

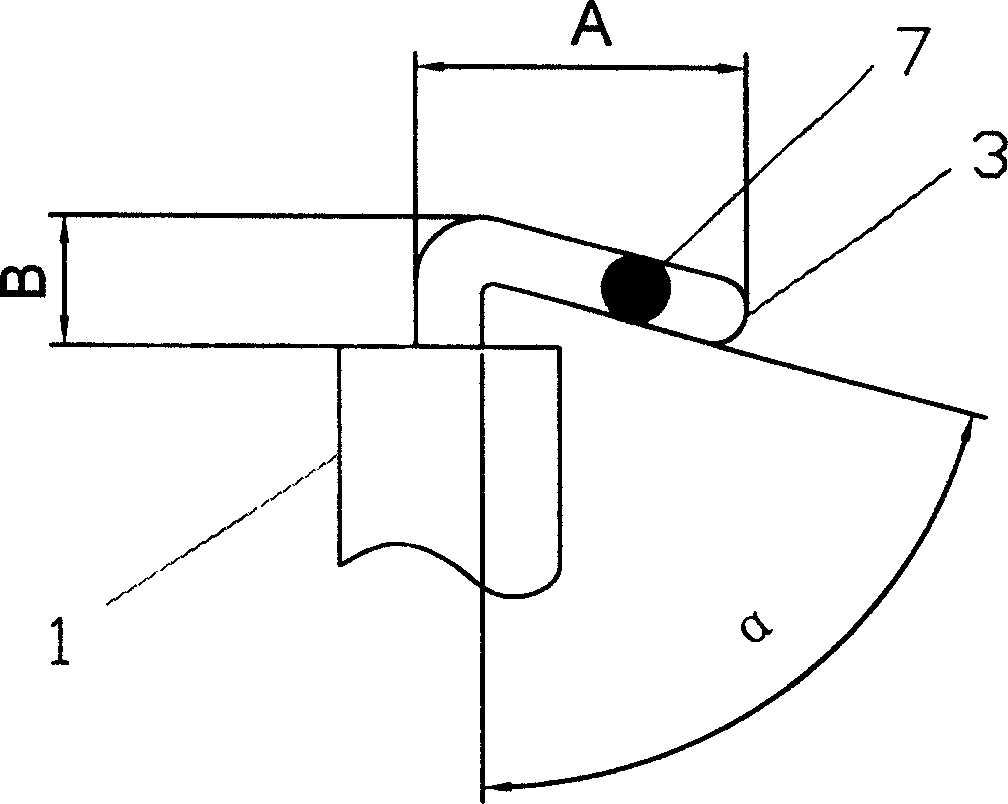

[0036] refer to image 3 , the fluorescent lamp tube of the present invention is improved in the prior art. Take the capillary tube that has been sealed, and first bend the exhaust tube once so that the height B is 5mm, the length A is 20mm, and the angle α is 60°, and then press The normal process is splicing, exhaust, scraping and post-processing. When scraping, the amalgam is positioned at the bent section to make R40, 23W energy-saving lamp tubes. The average initial luminous flux is 1400Lm, the average luminous flux maintenance rate is 83% after 4000 hours, and the service life reaches 10000 hours.

Embodiment 2

[0038] refer to Figure 4 , take the capillary pipe that has been sealed, and bend the exhaust pipe twice into a "Z" shape. The height B of the first bend is 2mm, the length A is 30mm, and the angle α is 90°. The length of the bend is that the length C is 2mm; then connect the fork, exhaust, lower the foot and post-process according to the normal process, and when the foot is lowered, position the amalgam at the second bending section to make R40, 23W energy-saving lamp tubes . The average initial luminous flux is 1350Lm, the average luminous flux maintenance rate is 84% after 4000 hours, and the service life reaches 10000 hours.

Embodiment 3

[0040] refer to Figure 4 , take the capillary that has been sealed, and first bend the exhaust pipe twice into a "Z" shape, where the height B of the first bend is 20mm, the length A is 5mm, and the angle α is 80°, the second bend The length of the bend is that the length C is 25mm; then the fork connection, exhaust, lower legs and post-processing are performed according to the normal process to make R40, 23W energy-saving lamp tubes. The average initial luminous flux is 1380Lm, the average luminous flux maintenance rate is 82% after 4000 hours, and the service life reaches 10000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com