Preparing method of ultra low sulfur diesel fuel possessing modified color quality

A technology of ultra-low sulfur diesel oil, properties, applied in the treatment of hydrocarbon oil, petroleum industry, liquid carbon-containing fuels, etc., can solve the problem of increasing sulfur content, unable to achieve sulfur content equal to or less than 10ppm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

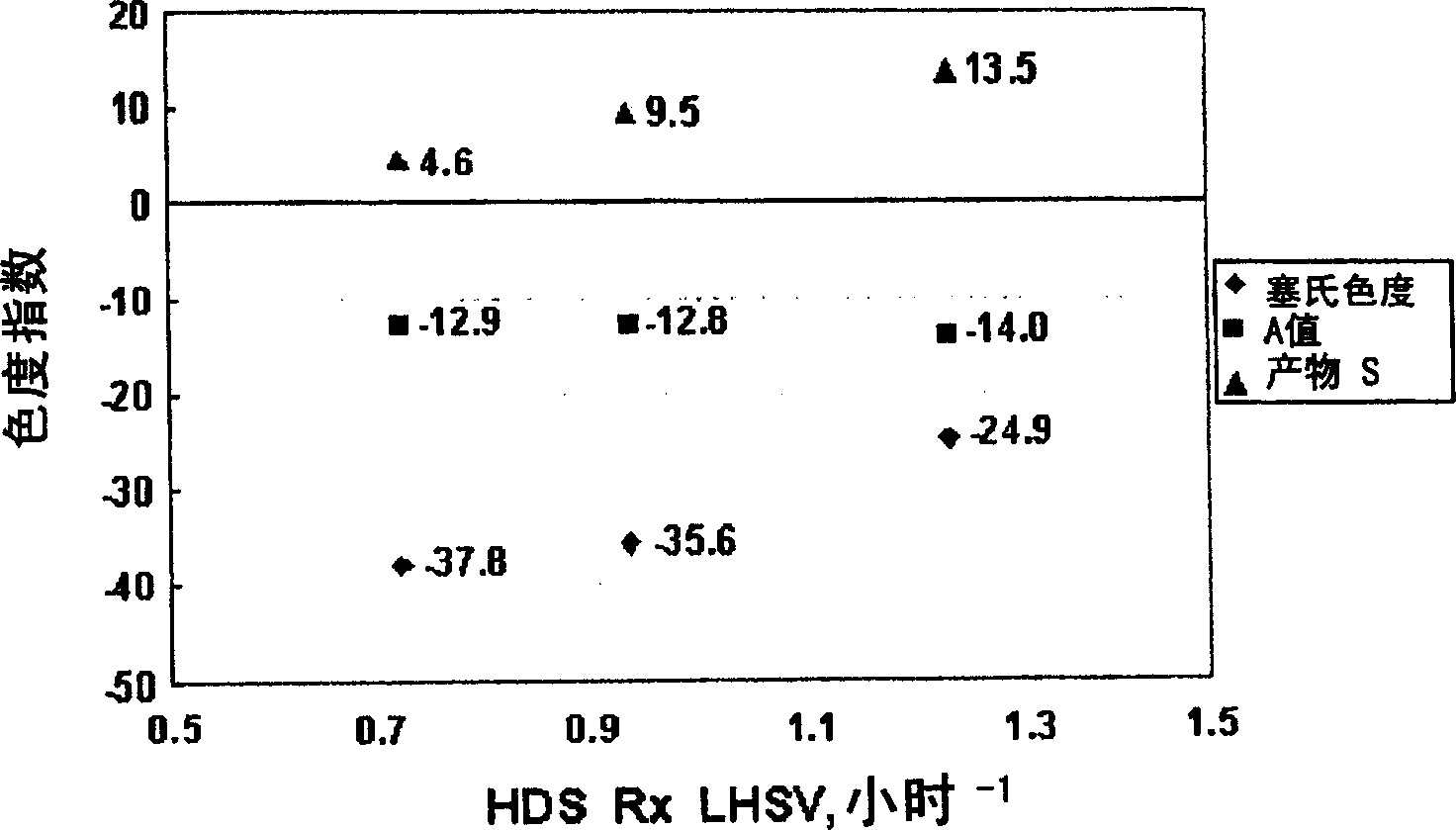

[0055] image 3The sulfur content and color index of the deep HDS product are shown as a function of LHSV at a fixed temperature of 370°C. As shown in the graph, as the LHSV decreases, the sulfur content in the product decreases to equal to or less than 5 ppm, but the color properties further deteriorate.

Embodiment 2

[0057] Changes in sulfur content before and after hydrotreatment for color improvement (LHSV: 5, reaction temperature: 260° C.) were compared according to deep HDS conditions. Figure 4 Shown is the change in sulfur content as a function of LHSV of the desulfurization reaction before and after hydrotreatment at a fixed temperature (370°C). in addition, Figure 5 is shown at fixed LHSV (0.94 hr -1 ), the change of sulfur content with the reaction temperature of HDS before and after hydrotreatment.

[0058] Depend on Figure 4 It can be seen that as the LHSV decreases in HDS conditions, the sulfur content in the fluid to be fed to the hydrotreating reactor decreases. However, the sulfur content increases again during hydrotreatment. When applying hydrotreatment to improve color properties, it was confirmed that LHSV changes in HDS have little effect on the sulfur content in the final product.

[0059] according to Figure 5 , when the reaction temperature in the deep HDS c...

Embodiment 3

[0063] By observing whether any kind of sulfur compounds increase during hydrotreating, it is possible to detect whether the increase in sulfur compounds is due to measurement error or the formation of other sulfur compounds. For this purpose, sulfur species were analyzed by gas chromatography, Figure 6 Chromatograms of three samples are shown. From Figure 6 As can be seen, it is confirmed that the increase in sulfur content during hydrotreating is due to the formation of new sulfur compounds and not due to measurement errors.

[0064] The chromatogram of a sample of 360R2-1 (S: 22 ppm) desulfurized at 360°C followed by hydrotreating agrees with the chromatogram of sulfur compounds in the product desulfurized by conventional methods. Peaks C and D show the refractory sulfur compounds 4-methylthiophene (dibenzothiophene) and 4,6-dimethylthiophene.

[0065] The 385R1-1 (S: 7 ppm) sample corresponds to the feed for hydrotreatment after the desulfurization reaction at 385°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com