Printed circuit board inspecting method and apparatus inspection logic setting method and apparatus

A substrate inspection and setting method technology, which is applied to measuring devices, optical devices, image data processing, etc., can solve the problems of difficult substrate inspection, high device cost, and large capacity, and achieve simple and high-speed processing and suppression The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

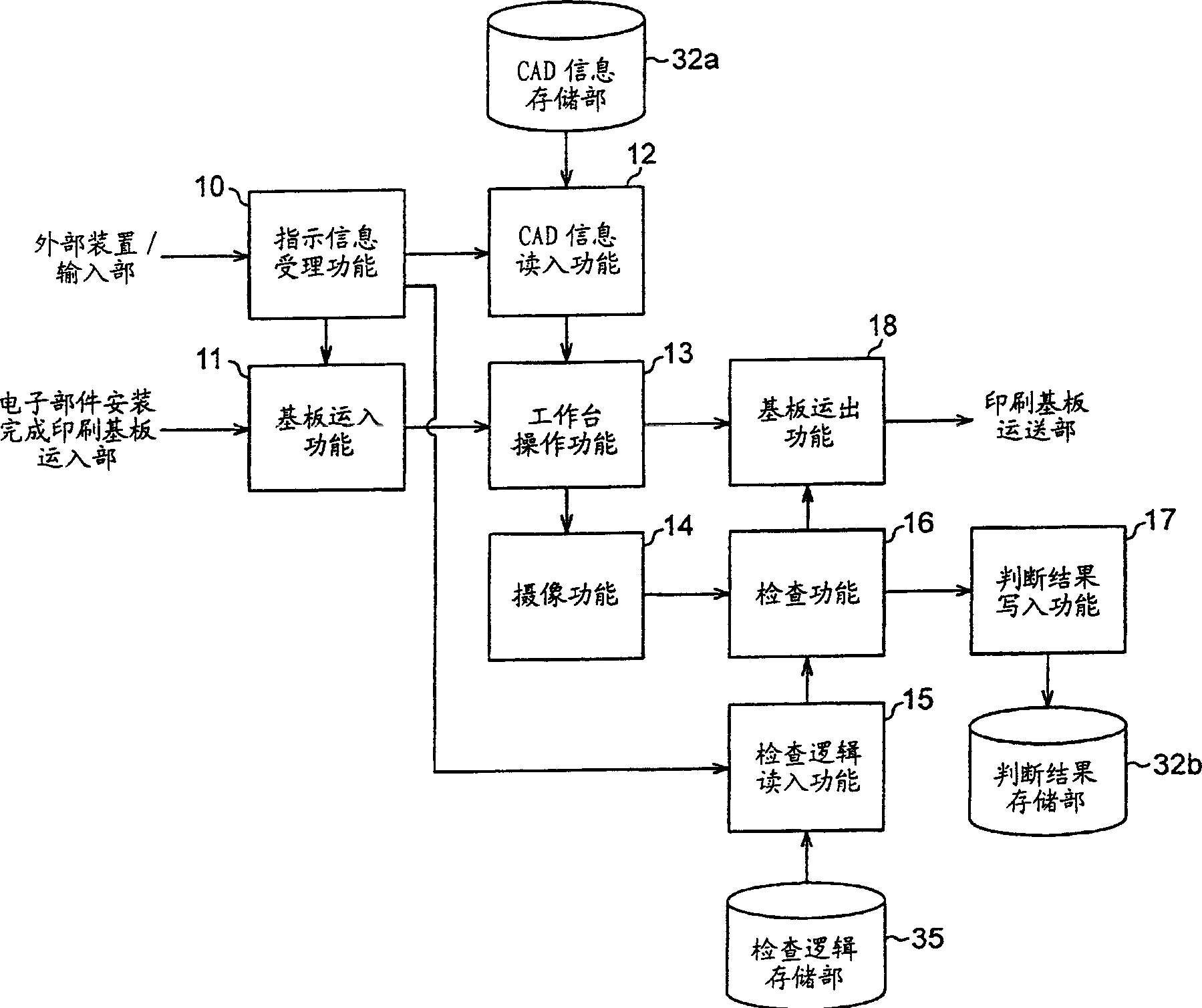

[0068] (Structure of board inspection system)

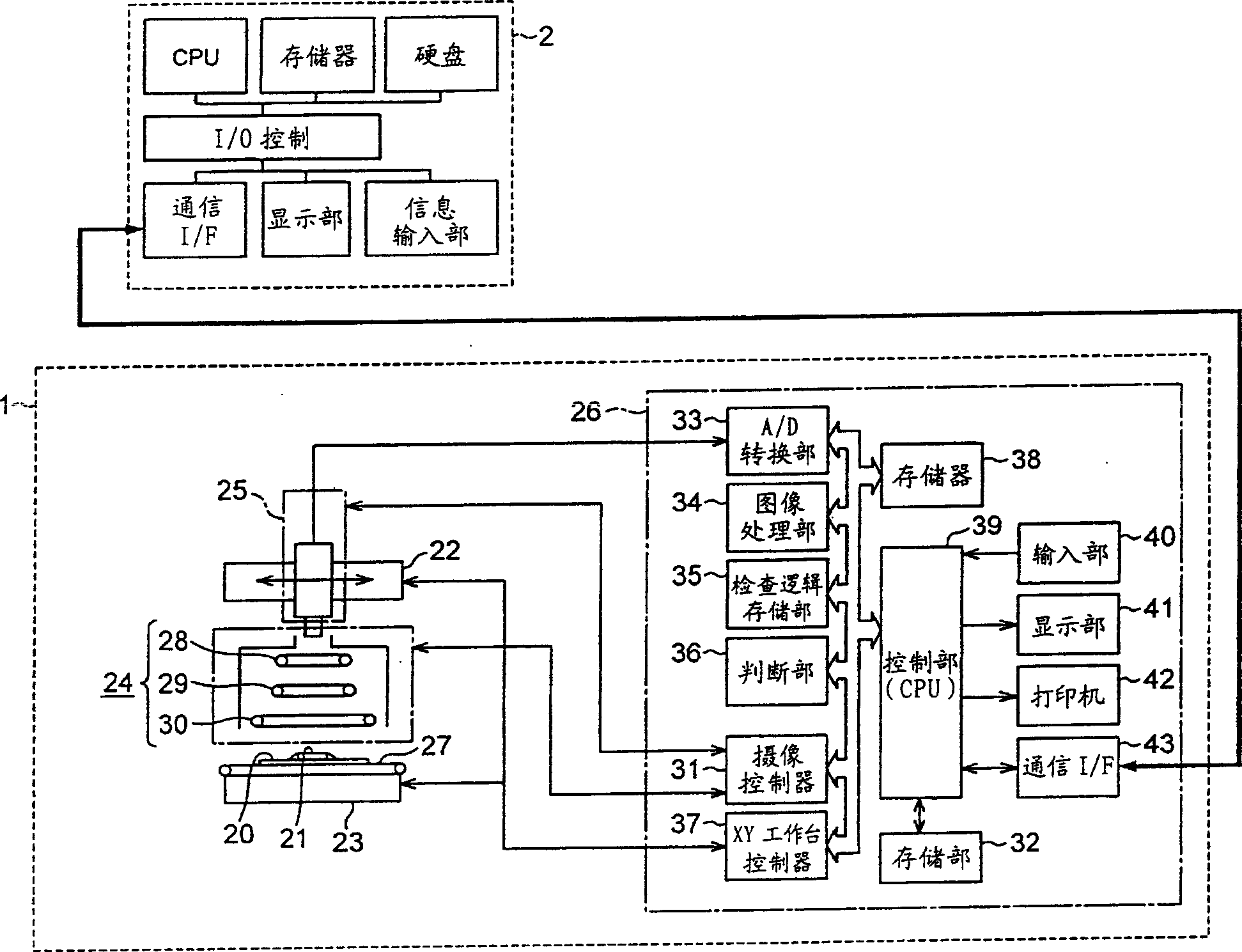

[0069] figure 1 The hardware configuration of the substrate inspection system according to the embodiment of the present invention is shown.

[0070] The substrate inspection system includes a substrate inspection device 1 that executes substrate inspection processing, and an inspection logic setting device 2 that automatically generates inspection logic used in the substrate inspection process of the substrate inspection device 1 . The substrate inspection device 1 and the inspection logic setting device 2 can be performed via a wired or wireless network, or a recording medium such as MO or DVD. image or transfer of electronic data such as parameters. In addition, in the present embodiment, the substrate inspection device 1 and the inspection logic setting device 2 are separate structures, but the substrate inspection device body may incorporate the function of the inspection logic setting device to form an integrated structu...

no. 2 approach

[0137] In the above-described first embodiment, the misalignment of the IC-based component is inspected focusing on the edge of the component main body portion. However, depending on the type of part, there may be deviation or unevenness in the color distribution of the main part of the part, making it difficult to determine the edge. For example, when characters or symbols are printed on the surface of the component body, or when the surface of the component body is deformed by heating during reflow, etc., color unevenness of the component body may occur. Therefore, in the second embodiment of the present invention, focusing on the fact that a plurality of leads are arranged linearly along the edge in IC components, the straight line connecting the plurality of leads (hereinafter referred to as " The position and angle of the lead alignment line"), thereby checking for component misalignment.

[0138] (Substrate inspection processing)

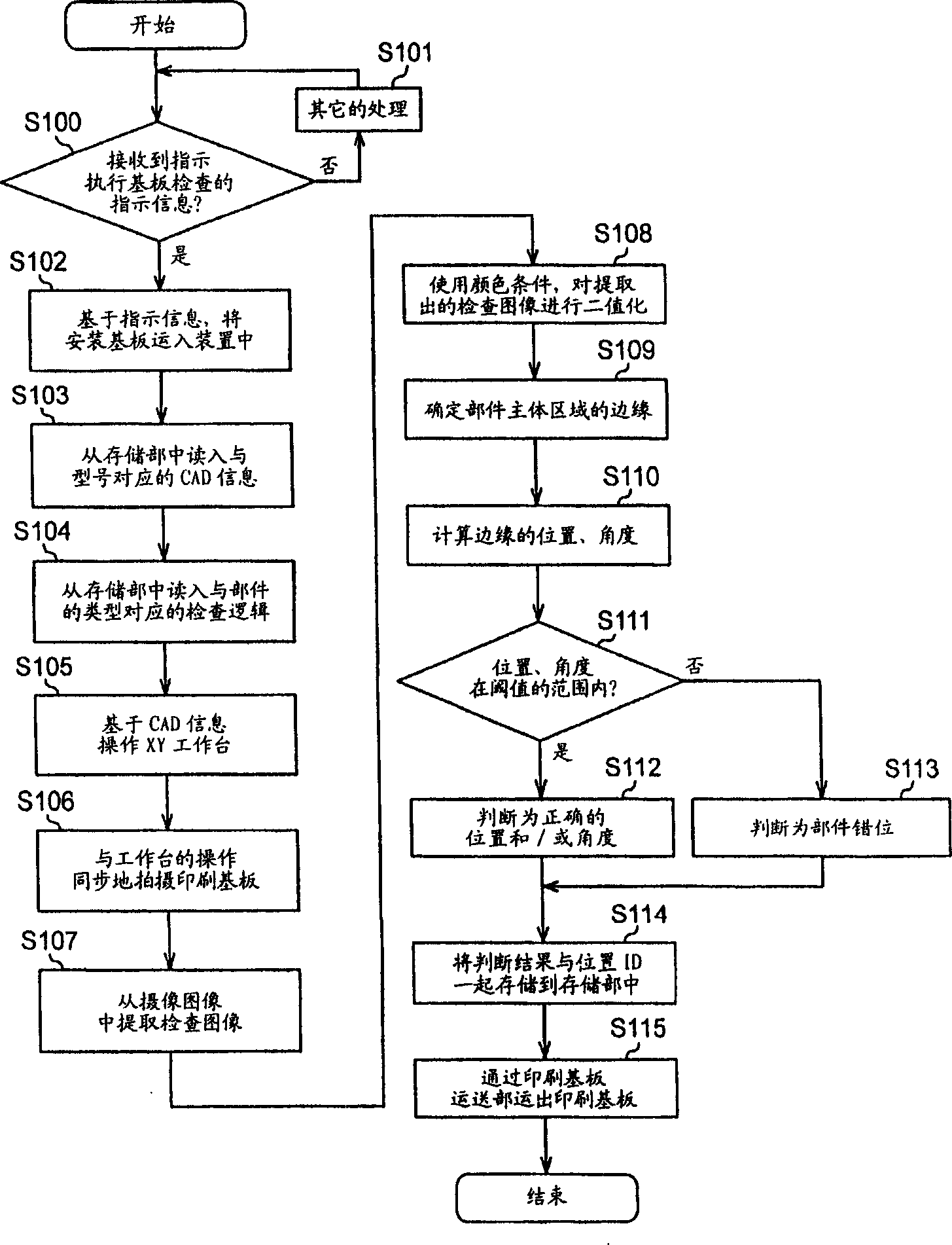

[0139] First, refer to Figure 12 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com