Organic electroluminesent panel

An electroluminescent, organic technology, applied in the field of organic electroluminescent panels, can solve problems such as peeling, strong mechanical stress, and easy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The organic electroluminescence panel of the present invention will be described in detail with reference to the diagrams, and preferred embodiments will be listed for illustration.

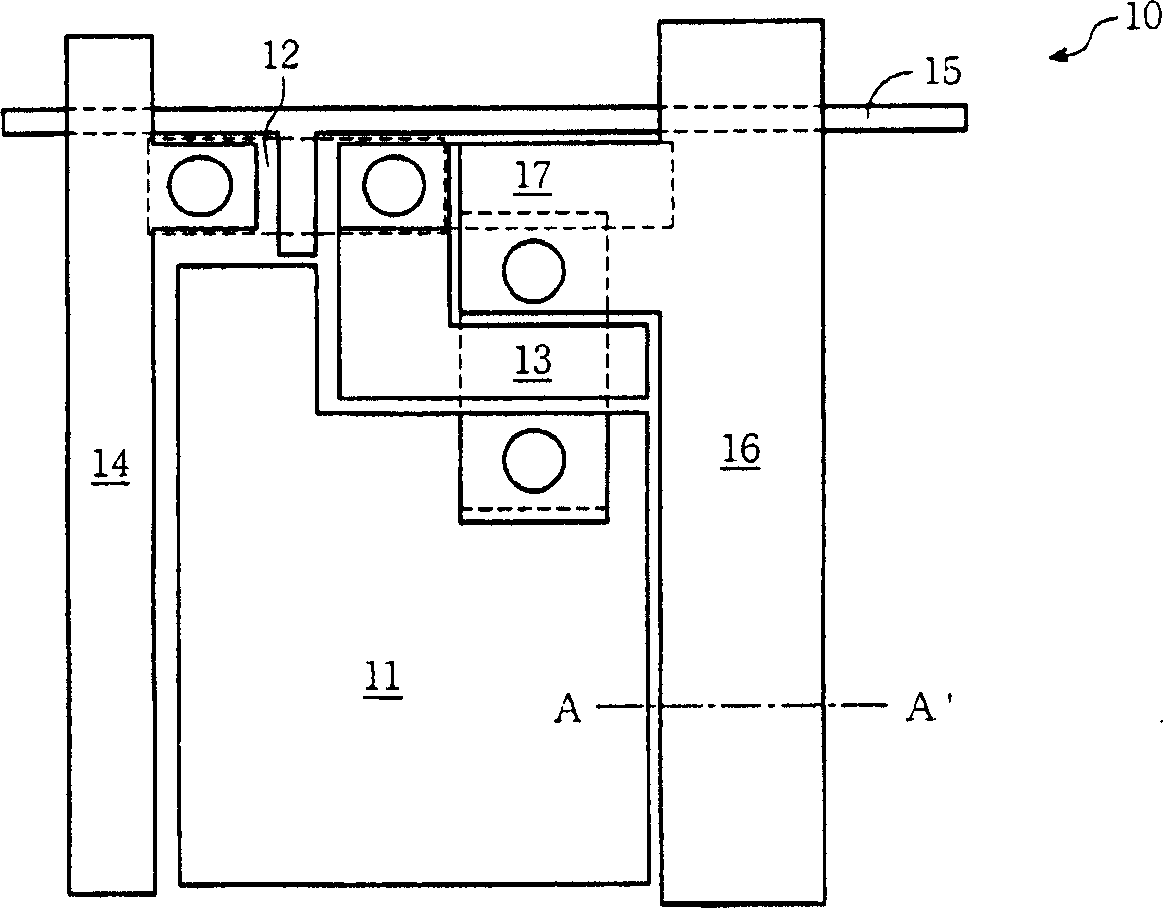

[0045] Please refer to figure 2 , is the top view of the appearance of the organic electroluminescence panel of the present invention. The organic electroluminescence panel 200 has a first substrate 210 and a second substrate 220 . There is an adhesive area 230 between the first substrate 210 and the second substrate 220 for the two substrates 210 and 220 to be pasted together. figure 2 The first substrate 210 is located below the second substrate 220 and overlapped with a flexible circuit board 240 . The second substrate 220 can serve as a packaging cover to protect the circuit structure on the first substrate 210 .

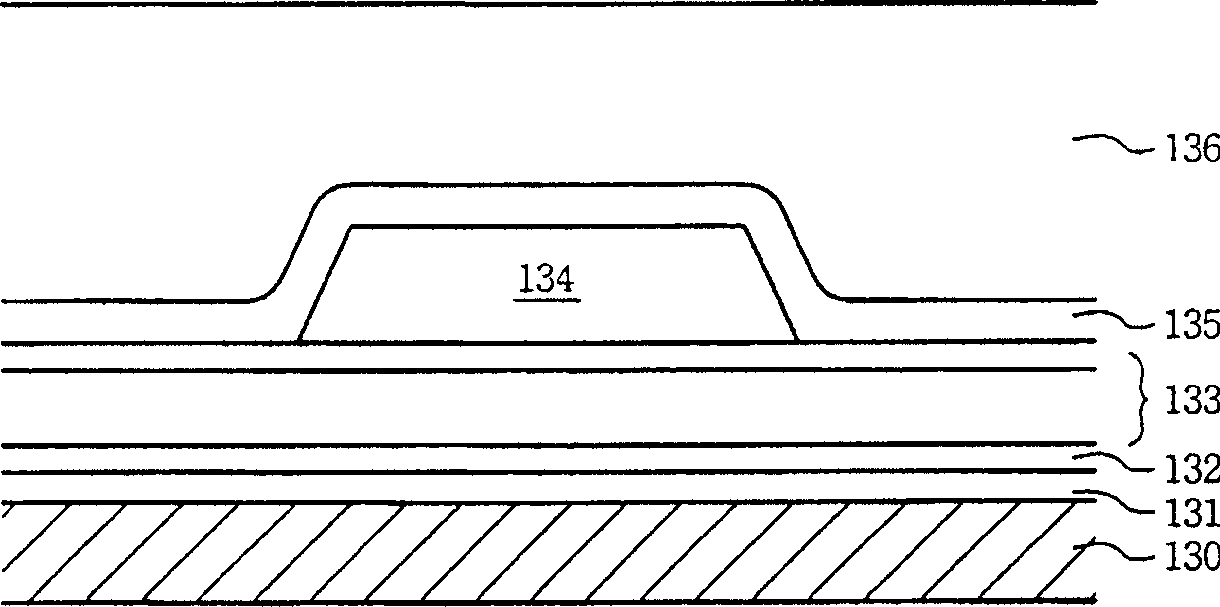

[0046] Please refer to image 3 , is a B-B sectional view of the organic electroluminescence panel 200 . A first conductive layer 212 and a pixel array 214 are dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com