Full-operating mode underwater anode block welding image detecting system

A detection system and underwater camera technology, applied in closed-circuit television systems, photography, optics, etc., can solve problems such as low imaging resolution and short camera operation time, and achieve low cost, real-time observation data, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

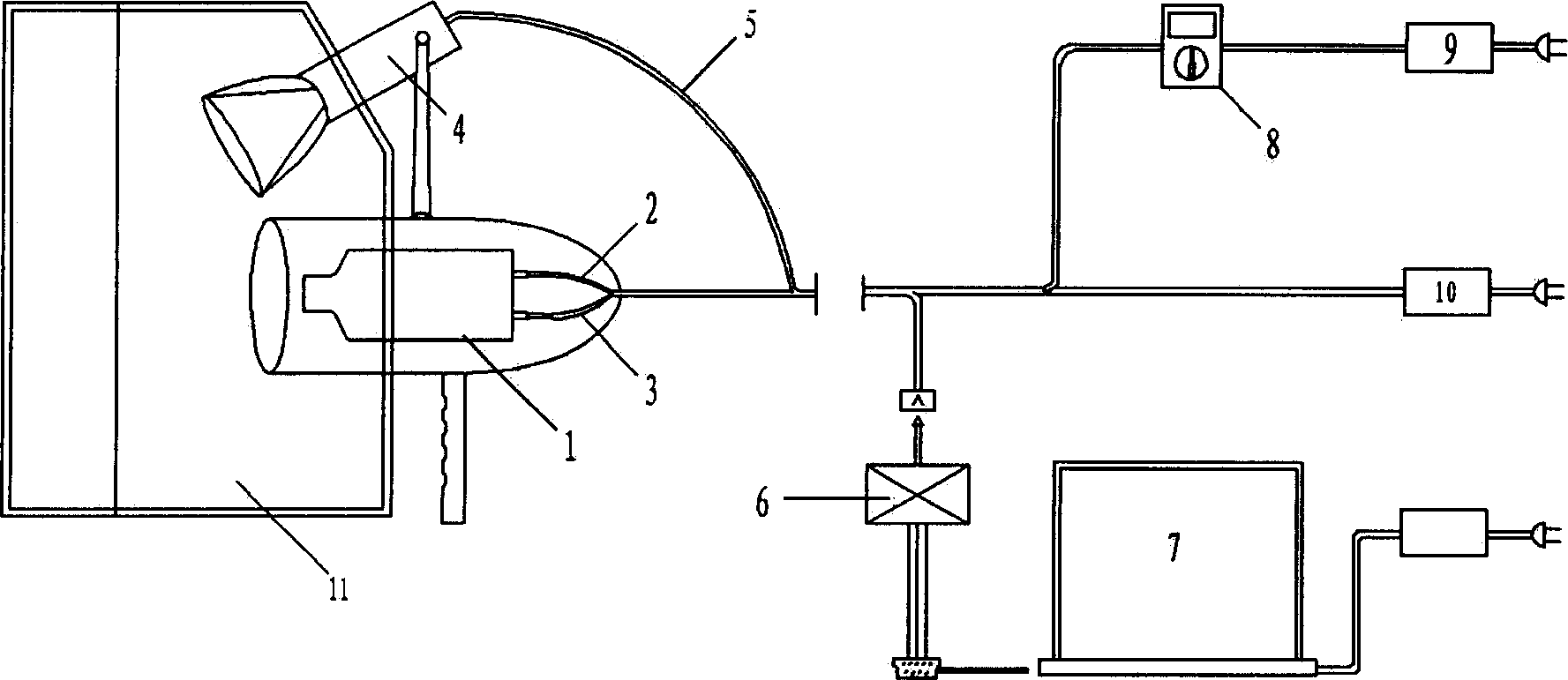

[0016] Such as figure 1 As shown, the full working condition underwater anode block welding camera detection system includes five subsystems, namely underwater camera system, data transmission system, image display system, muddy water camera auxiliary system, and underwater lighting system.

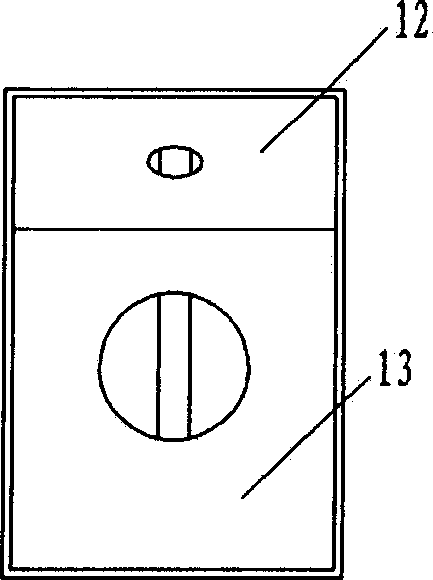

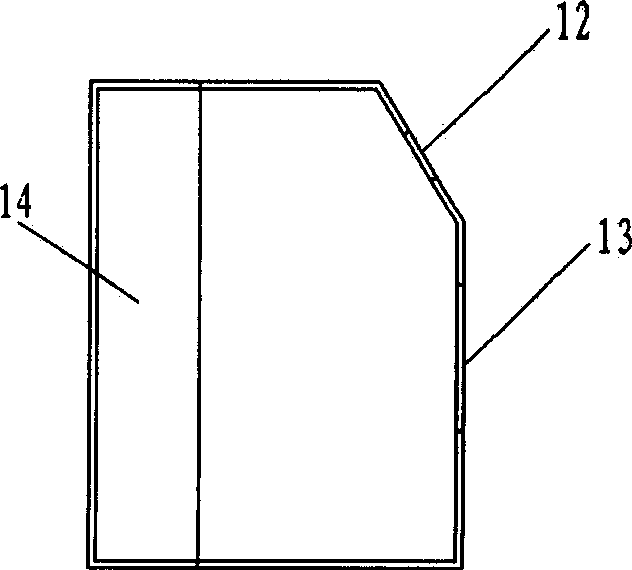

[0017] The underwater camera system consists of a 650-line color camera 1 with a copper waterproof cover, a 30w / 12v switching power supply 10, and a camera power cord 2;

[0018] The muddy water camera auxiliary system is composed of a plexiglass camera cover 11;

[0019] The data transmission system is made up of data transmission line 3 and A / D converter 6;

[0020] The image display system includes a computer 7 and professional camera real-time display and processing software;

[0021] The underwater lighting system consists of a 100w / 12v strong spotlight 4 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com