Three-dimensional integral weaving method capable of changing weaving forming direction

An integral weaving and three-dimensional technology, applied in the field of three-dimensional weaving, can solve the problems of destroying the integrity of preformed parts, waste of materials, part performance, and increase the manufacturing cost of parts, so as to improve integrity and comprehensive performance and reduce processing procedures , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

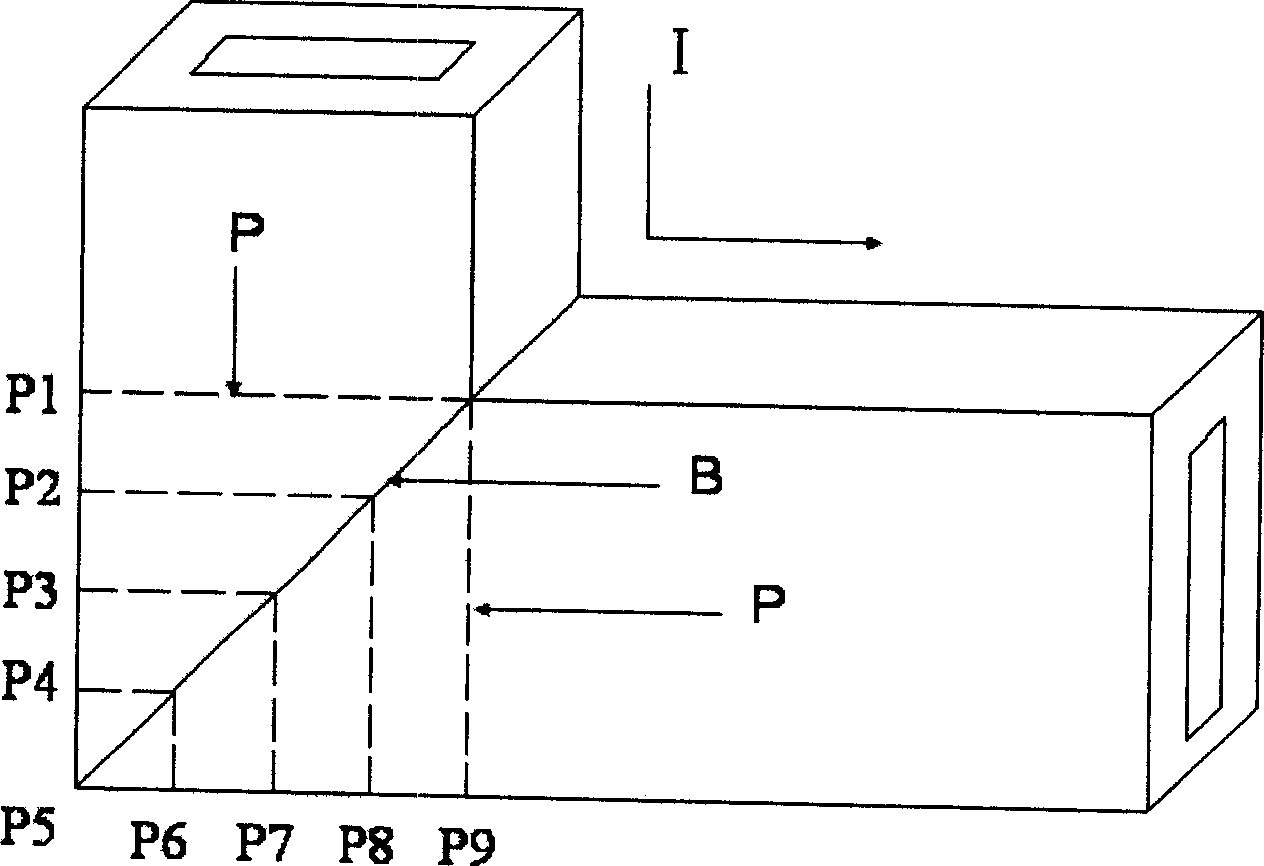

[0037] Adopt braiding method of the present invention to weave box-type right-angle joint parts (referring to figure 1 , 5 ).

[0038] The cross-sectional size of the box-shaped part is 45*45mm, and the thickness of each side is 7mm. The four-step method is used for three-dimensional and five-directional square weaving. The direction perpendicular to the cross-section of the box-shaped part is the weaving forming direction I, and the knitting yarn 3 is T300-6K carbon fiber, the weaving angle is 22°, and the number of yarns required for design weaving is 2108. The cross-sectional parts of the box-shaped parts with knot line P1 and above are woven by the traditional square weaving method, that is, all the yarns along this direction participate in the weaving. The left turning part below the knot line P1 is braided by the partial braiding method of the present invention. From P1, weave one knuckle length of all yarns to the position of P2. According to the length of the knuckl...

Embodiment 2

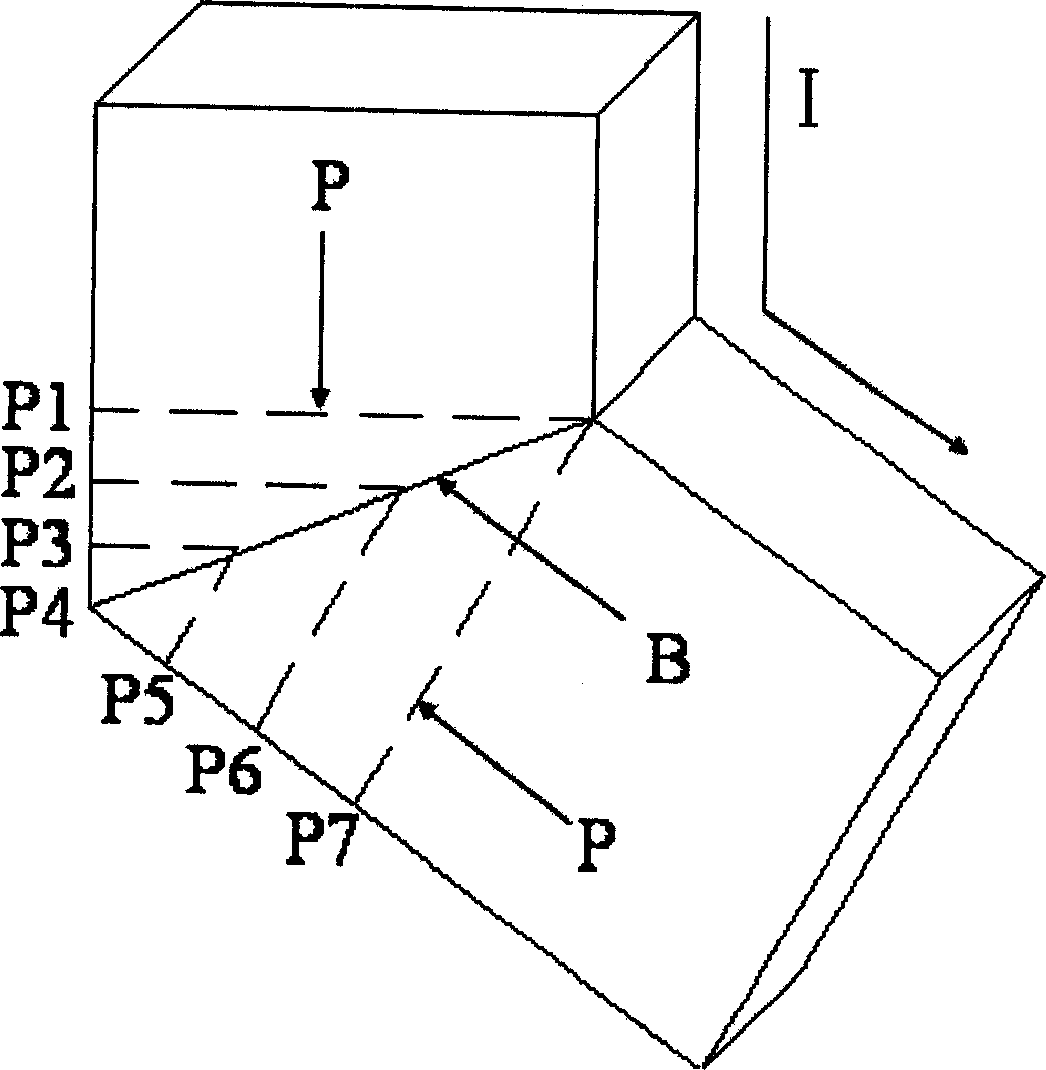

[0041] Adopt weaving method of the present invention to weave folded bar parts (referring to figure 2 ).

[0042] The cross-section of the folding rod is rectangular, the size is 35*8mm, the weaving adopts three-dimensional five-way structure, square weaving, the weaving yarn 3 is T300-12K carbon fiber, the weaving angle is 30°, and the number of yarns required for the design weaving is 296 root. The local weaving of the bending part is divided into two groups of 6 times (P1-P3, P5-P7). All the yarns at P1 participate in weaving, weave a flower node length to P2, and reduce the number of yarns participating in weaving to 188; weave a flower node length to P3 place, then reduce the number of yarns participating in weaving to 54; weave a flower node length and stop (P4 place); turn the part of the finished part to the folding rod system The angle required by the piece makes the unwoven part perpendicular to the braiding machine chassis 2. The knitting after bending starts fr...

Embodiment 3

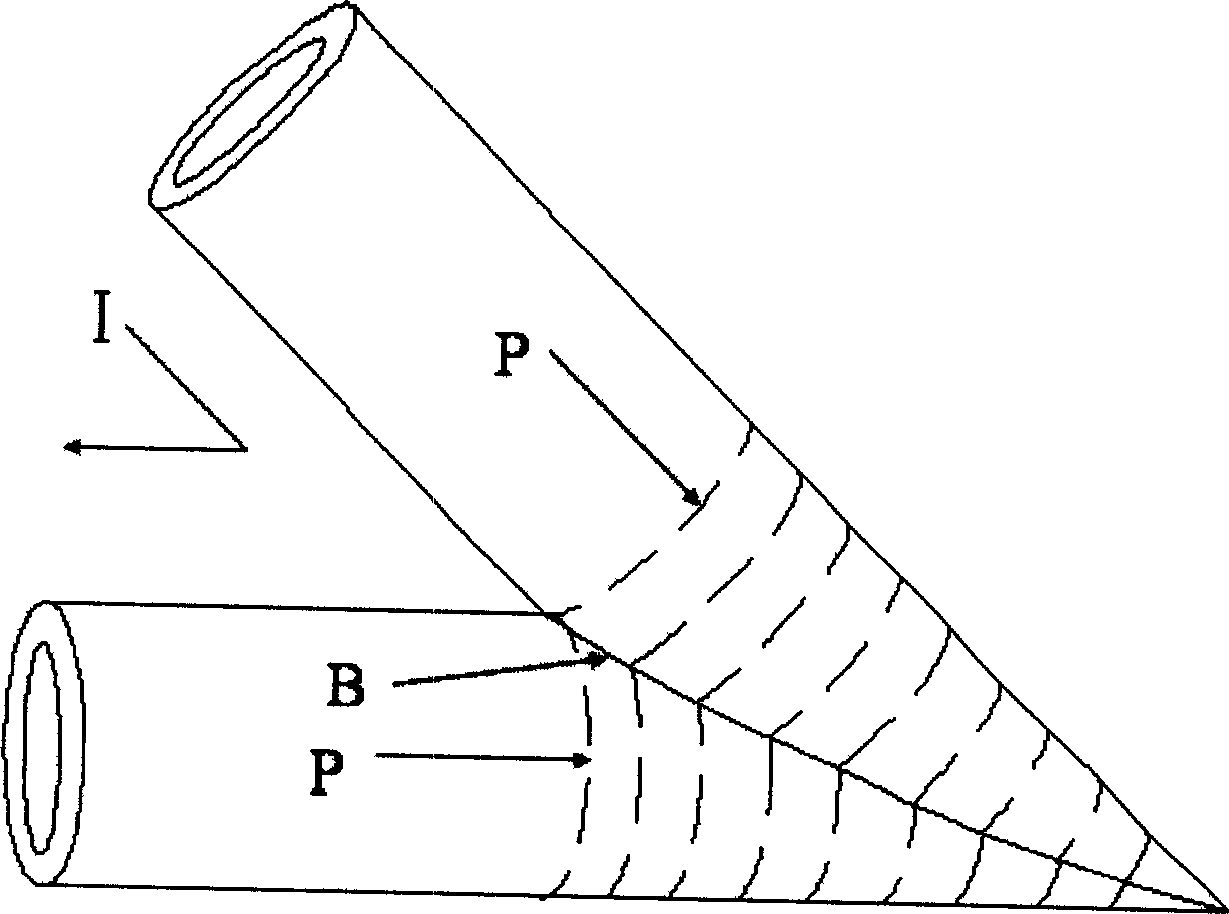

[0044] Adopt braiding method of the present invention to weave oblique circular pipe joint parts (see image 3 , 6 ),

[0045] The shape and structure of the two round pipes of the oblique round pipe joint are symmetrical, the inner diameter is 22mm, the outer diameter is 26mm, and the space included angle is 45°. The four-step three-dimensional five-directional structure circular weaving method is adopted, and the weaving yarn is 540tex glass fiber. , the braiding angle is 34°, the flower node length is 4.8mm, and the number of yarns required for the design weaving is 350. Taking the cross-sectional direction of the vertical round tube as the forming direction I, first weave the equal section part of the round tube to the knot line P with the traditional weaving method; secondly, according to the geometric dimensions of the turning part of the round tube, take the length of the knot as the pitch , design the knuckle line, calculate the length of the knuckle line and the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com