High-performance energy-saving boiler

A high-efficiency, energy-saving, boiler technology, applied in the field of boilers, can solve the problems of high energy consumption and low boiler heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

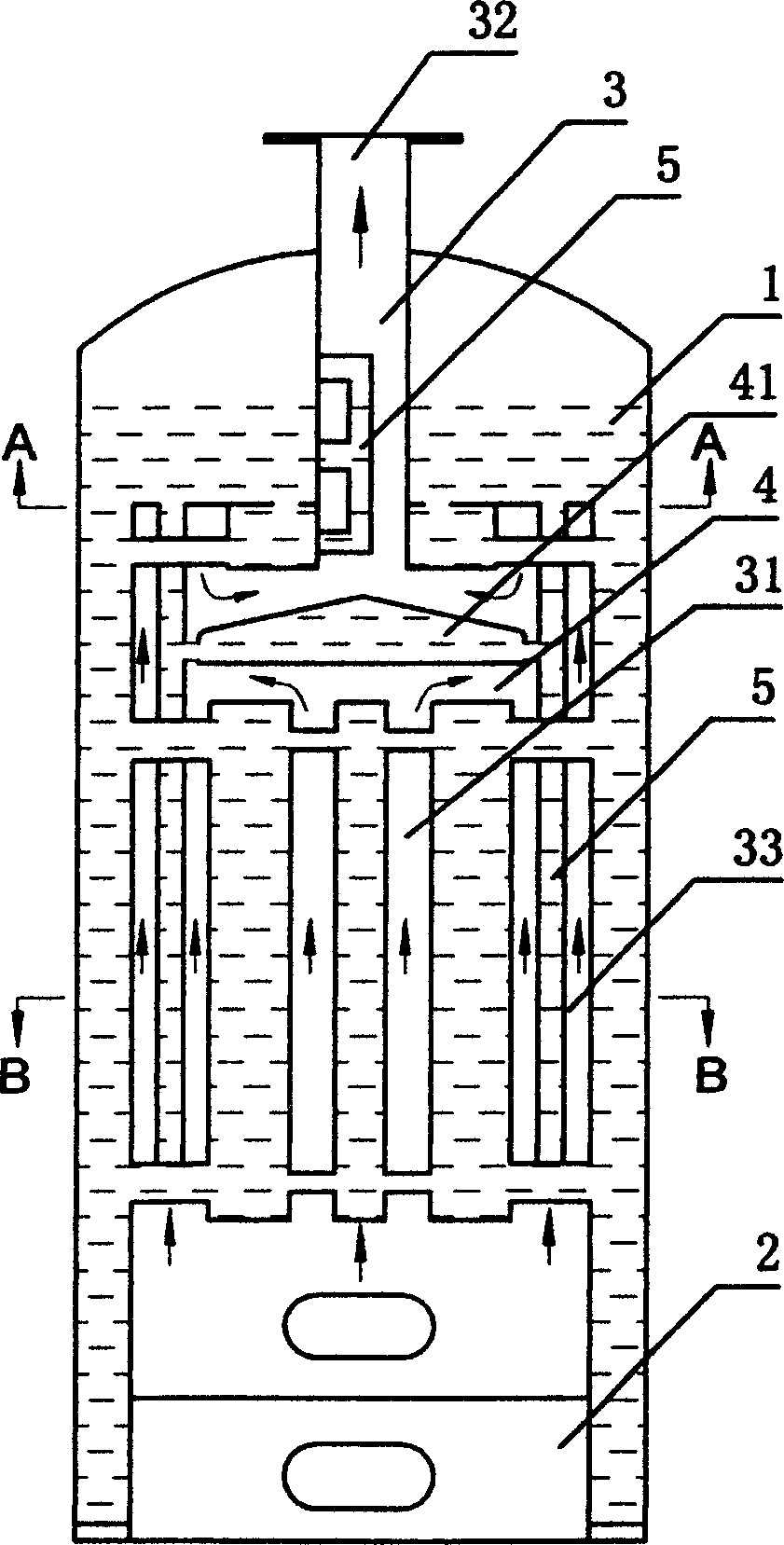

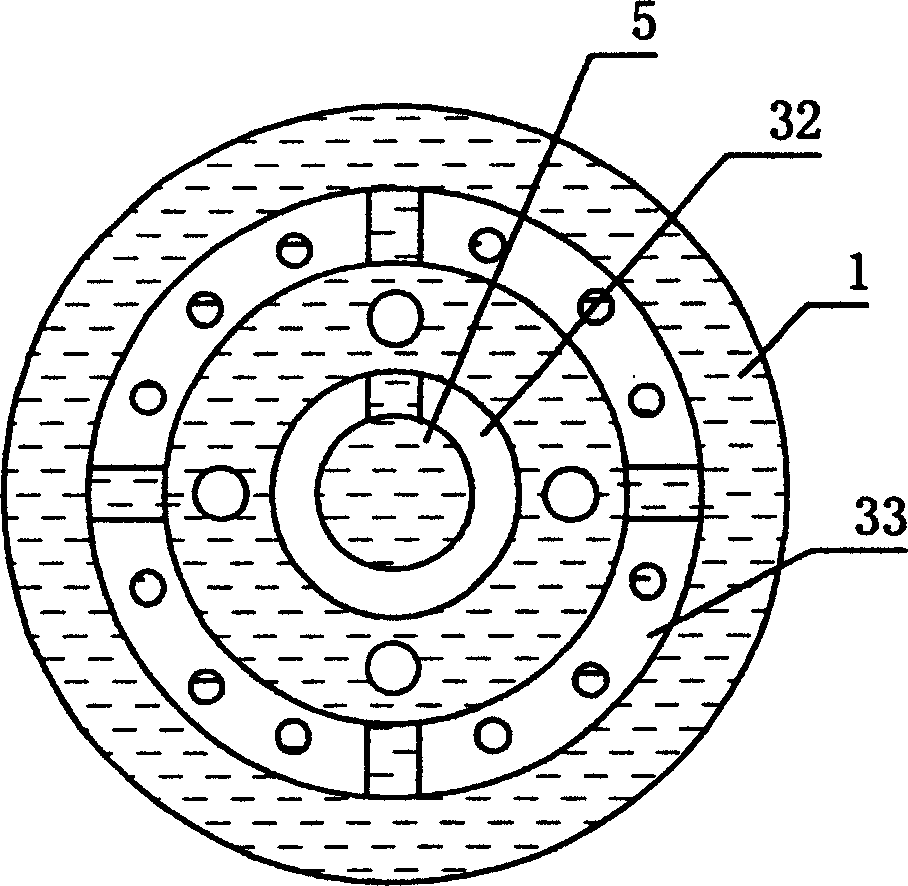

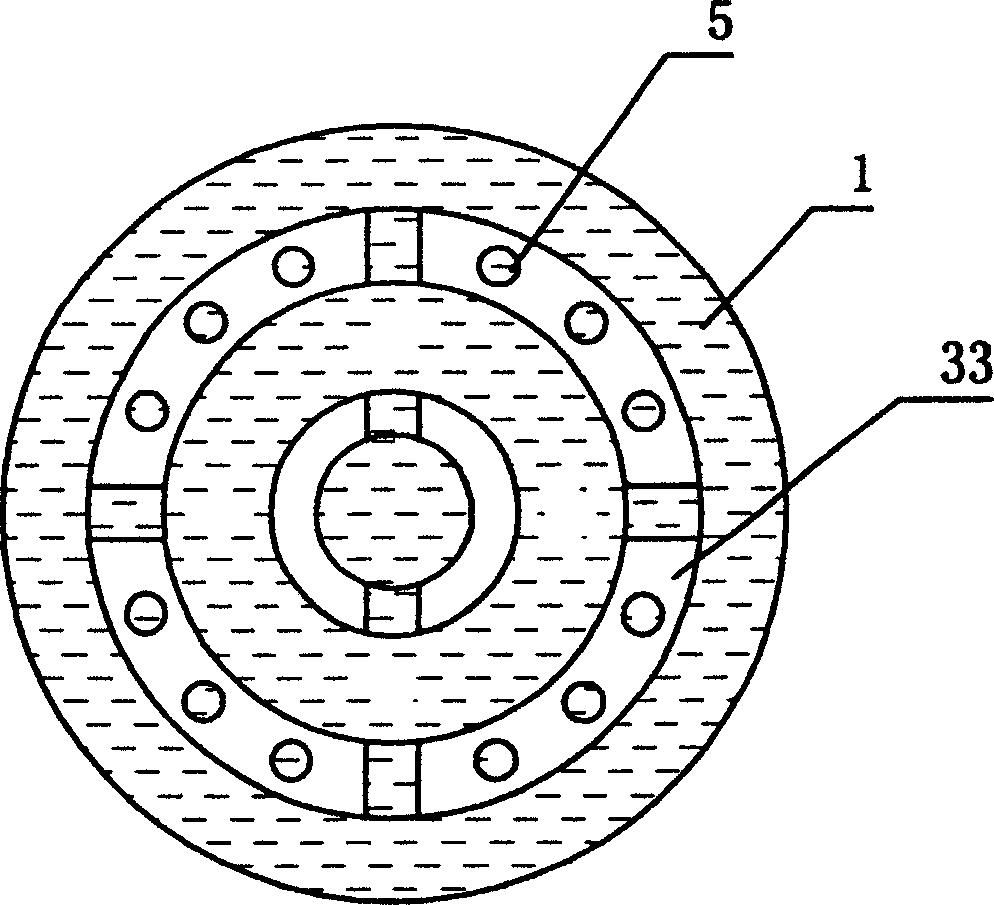

[0016] refer to figure 1 , figure 2 and image 3 , a kind of high-efficiency energy-saving boiler of the present invention is: comprise the furnace body of boiler, the outer surface of furnace body is provided with insulation layer, is provided with water jacket 1, combustion chamber 2, and ash box etc. in furnace body, passes through water jacket 1. There is a pyrotechnic channel 3 connecting the combustion chamber 2 and the outside of the top of the furnace body. The flame burned in the combustion chamber 2 passes through the pyrotechnic channel 3 and exchanges heat with the water in the water jacket 1 before being discharged from the boiler. Among them, the pyrotechnic passage 3 includes a fire passage 31 close to the end of the combustion chamber 2, and a flue passage 32 that communicates with the fire passage 31 and is away from the end of the combustion chamber 2, and the fire passage 31 is composed of at least one set of ring-shaped Combustion channel 33, such a stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com