A composite insulator and method for preparing same

A technology of composite insulators and insulating jackets, applied in the direction of insulators, suspension/strain insulators, electrical components, etc., to achieve the effect of improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

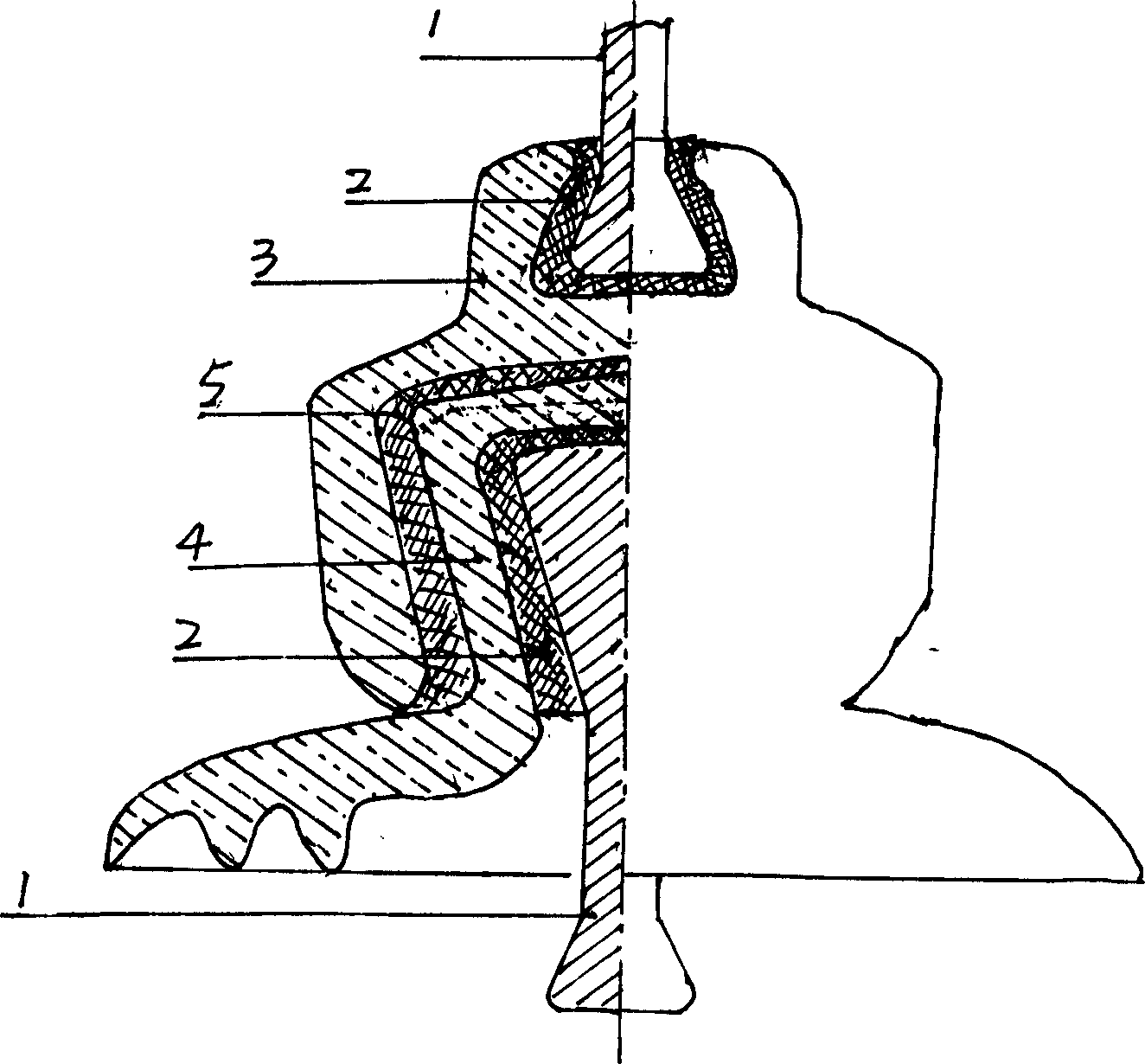

[0008] Referring to the accompanying drawings, the insulator of the present invention is composed of three independent parts: an umbrella plate 4 , an insulating jacket 3 and a connector 1 . The junction between the upper part of the umbrella plate 4 and the insulating jacket 3 has a conical structure on the inner and outer walls, the inner wall of the insulating jacket that is socketed with it is a conical structure, and the outer wall of the connecting piece that is socketed on the inside is a conical structure. The other end of the connecting piece also has a conical structure, and the upper part of the insulating jacket mated with it is also provided with an inner conical groove structure. After the conical structures are matched, the joints of all the conical structures are filled with filling materials, and the connection between the components is formed through the filling materials. And this kind of connection will continuously improve its own bonding force through its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com