Metal catalytic reactor

A catalyst and metal technology, applied in chemical instruments and methods, physical/chemical process catalysts, machines/engines, etc., can solve the problems of insufficient installation strength of the honeycomb sandwich body 4, shortened brazing length, etc., and achieve cost and weight reduction. , The effect of reducing thermal stress and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

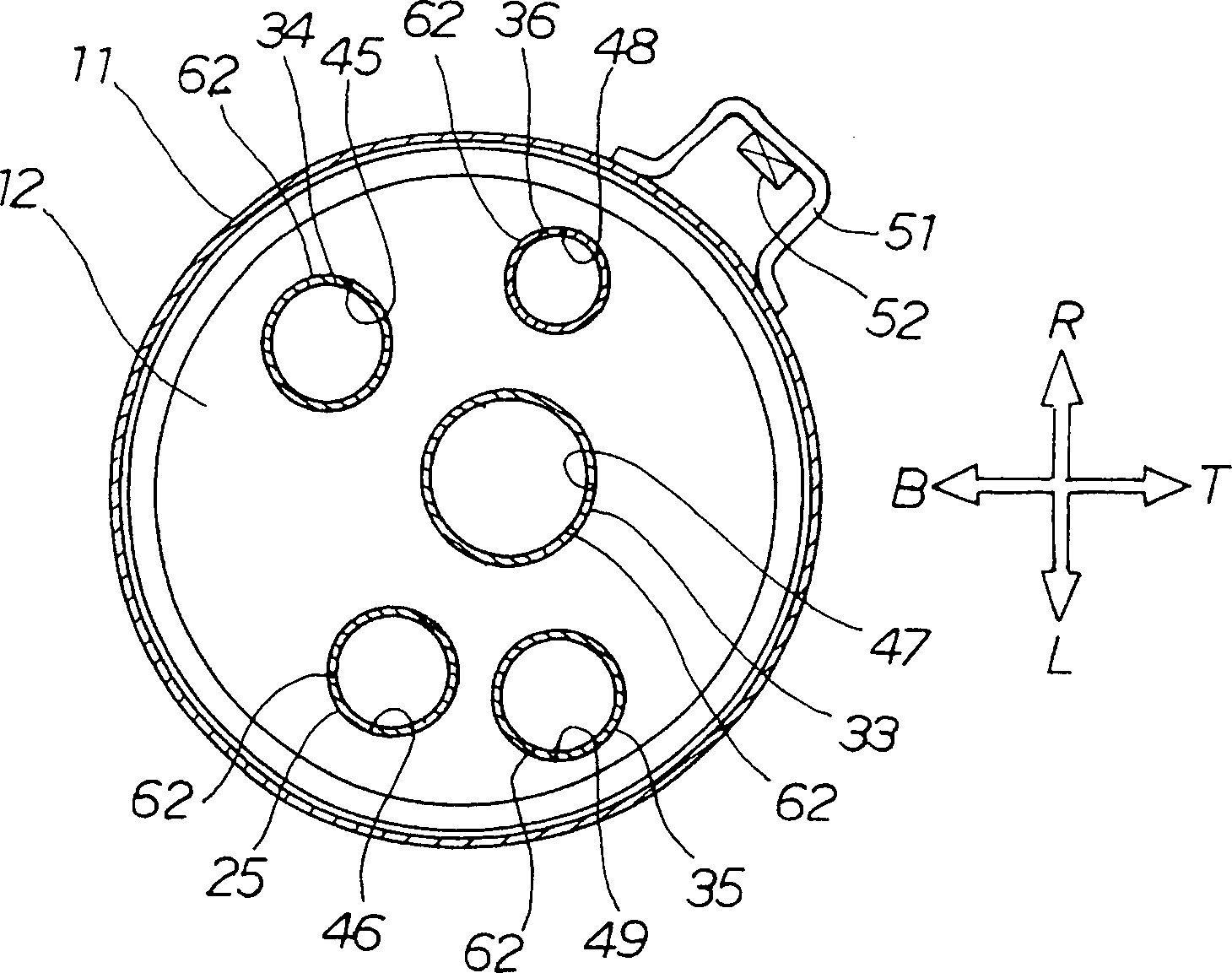

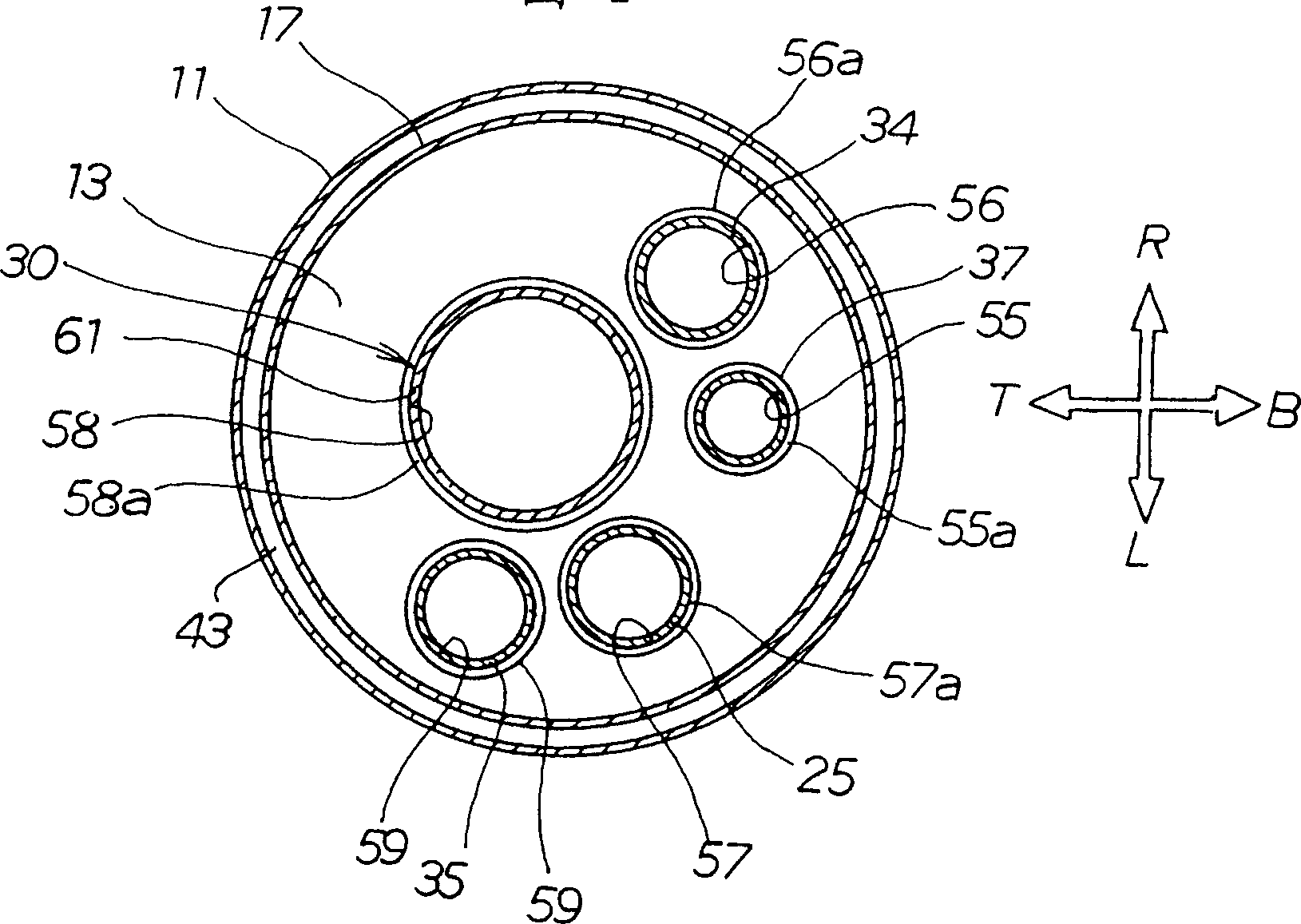

[0045] In the following descriptions, "front", "rear", "left", "right", "up", and "down" refer to the directions from the muffler, Fr indicates the front, and Rr indicates the rear , L means left side, R means right side, T means up, B means down. In addition, the drawings are diagrams viewed along the direction of symbols.

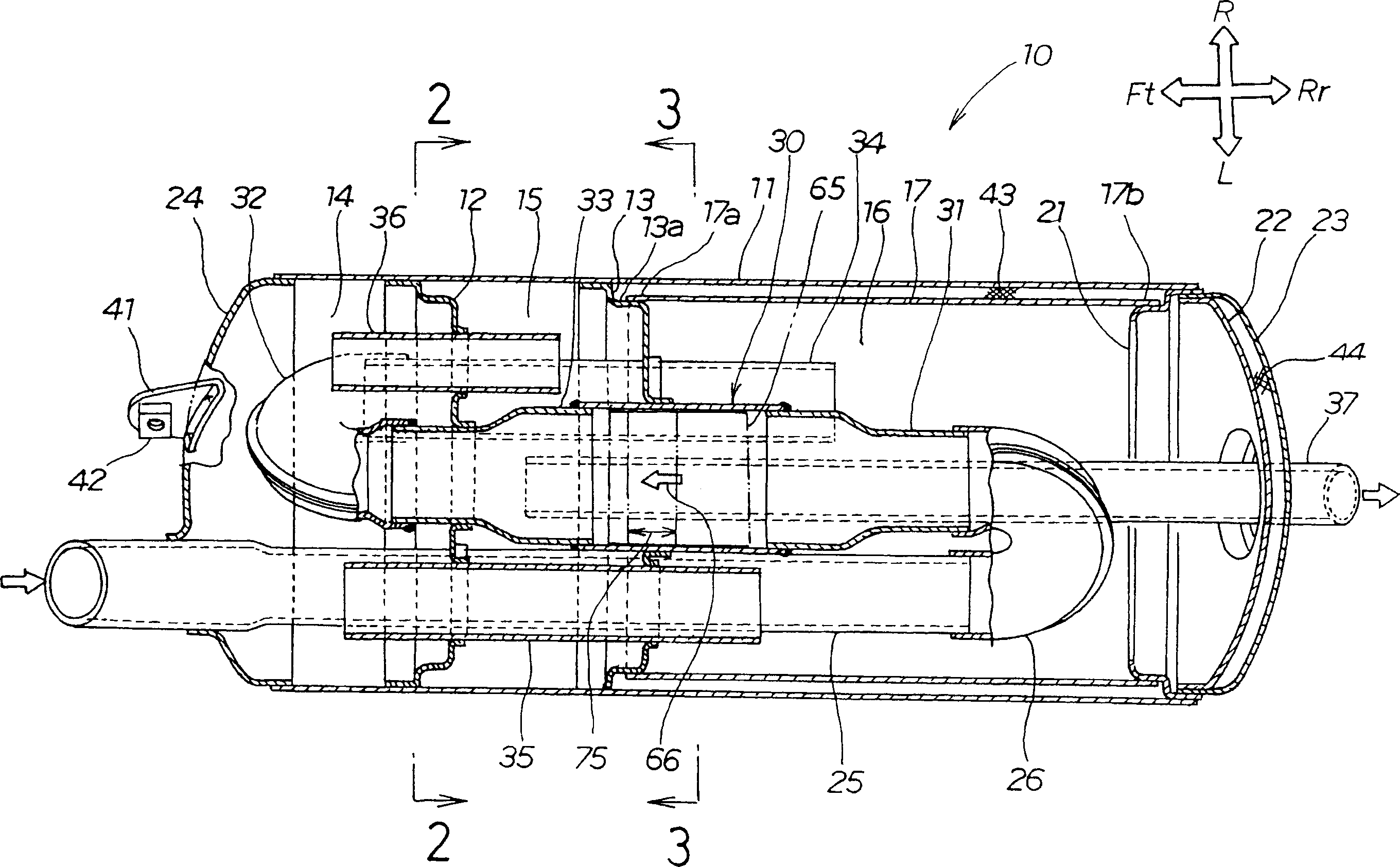

[0046] figure 1 It is a cross-sectional view of a muffler equipped with a metal catalytic converter of the present invention. The muffler 10 has: a cylindrical outer shell 11; The first partition 12 and the second partition 13 arranged behind the first partition 12 form a front chamber 14, a middle chamber 15, and a rear chamber 16 in the outer casing 11, which are arranged behind the second partition 13. side, and one end 17a is held by the circumferential shoulder 13a of the second partition 13; the annular ring member 21, which holds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com