Application of carbonaceous calcium mud rook in cement raw material

A technology for cement raw materials and calcium mud, applied in the field of cement, can solve the problems of increased cement cost, increased power consumption and coal consumption, increased investment, etc., and achieves the effects of reducing coal consumption, saving energy, and being easy to calcine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Dosing according to the stated proportion: take 45% of limestone, 50% of carbonaceous calcium mudstone, and 5% of steel slag; mix the above raw materials according to the stated proportion, grind and calcinate to obtain clinker, and the follow-up process is the same as the traditional cement production process.

Embodiment 2

[0045] Dosing according to the stated ratio: take 55% of limestone, 40% of carbonaceous calcium mudstone, and 3.5% of steel slag; mix the above raw materials according to the stated proportion, grind and calcinate to obtain clinker, and the follow-up process is the same as the traditional cement production process.

Embodiment 3

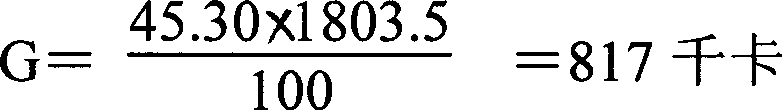

[0047]Dosing according to the stated ratio: take 51.20% of limestone, 45.30% of carbonaceous calcium mudstone, and 4.5% of steel slag; mix the above raw materials according to the stated proportion, grind and calcinate to obtain clinker, and the follow-up process is the same as the traditional cement production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com