Method for the determination of the caco3 content in a washing liquid

一种洗涤液、含量的技术,应用在分离方法、化学方法分析、化学仪器和方法等方向,能够解决pH值精度影响、影响可靠性、难以实现准确用量的监控等问题,达到准确混合、pH值精确的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

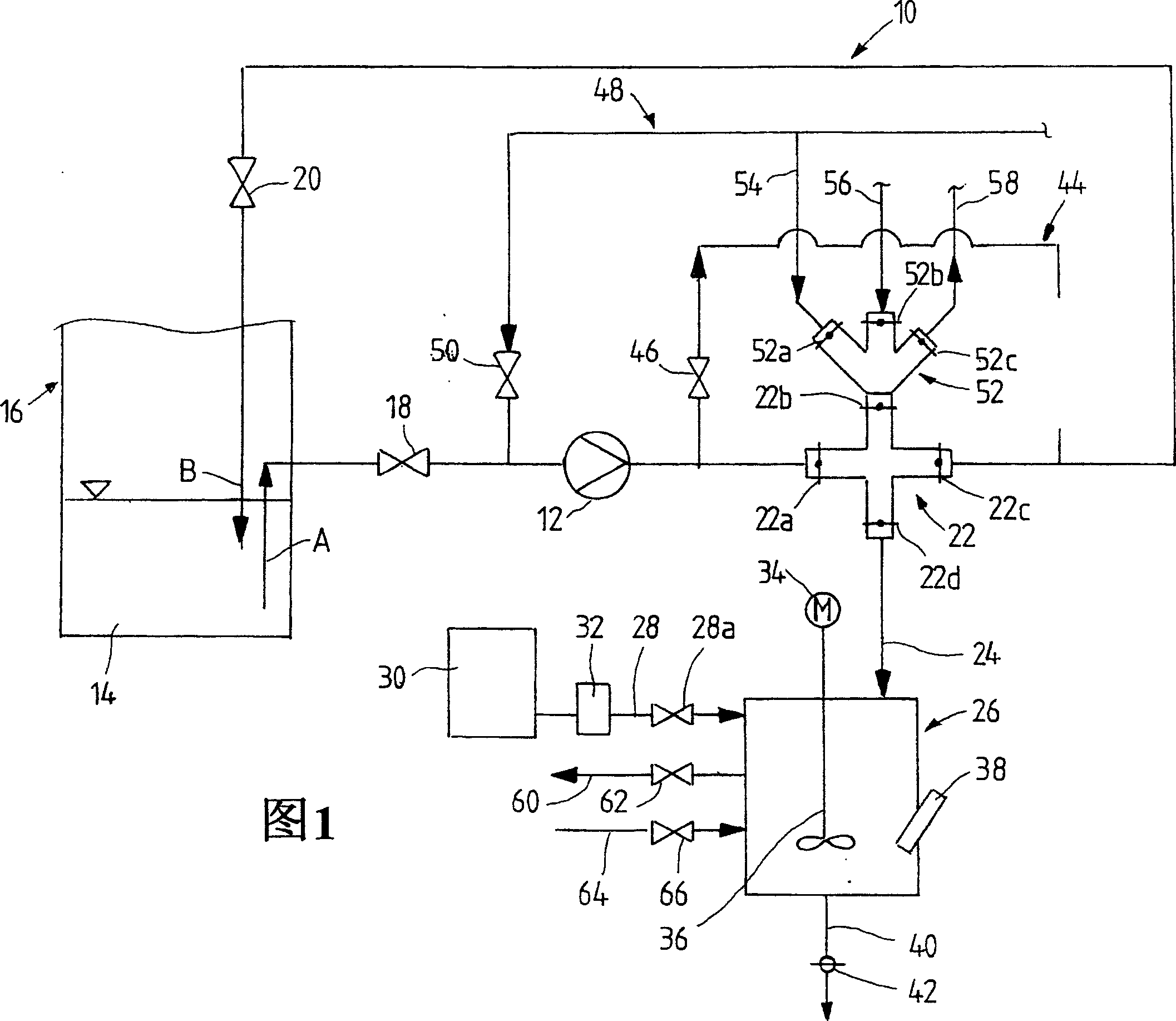

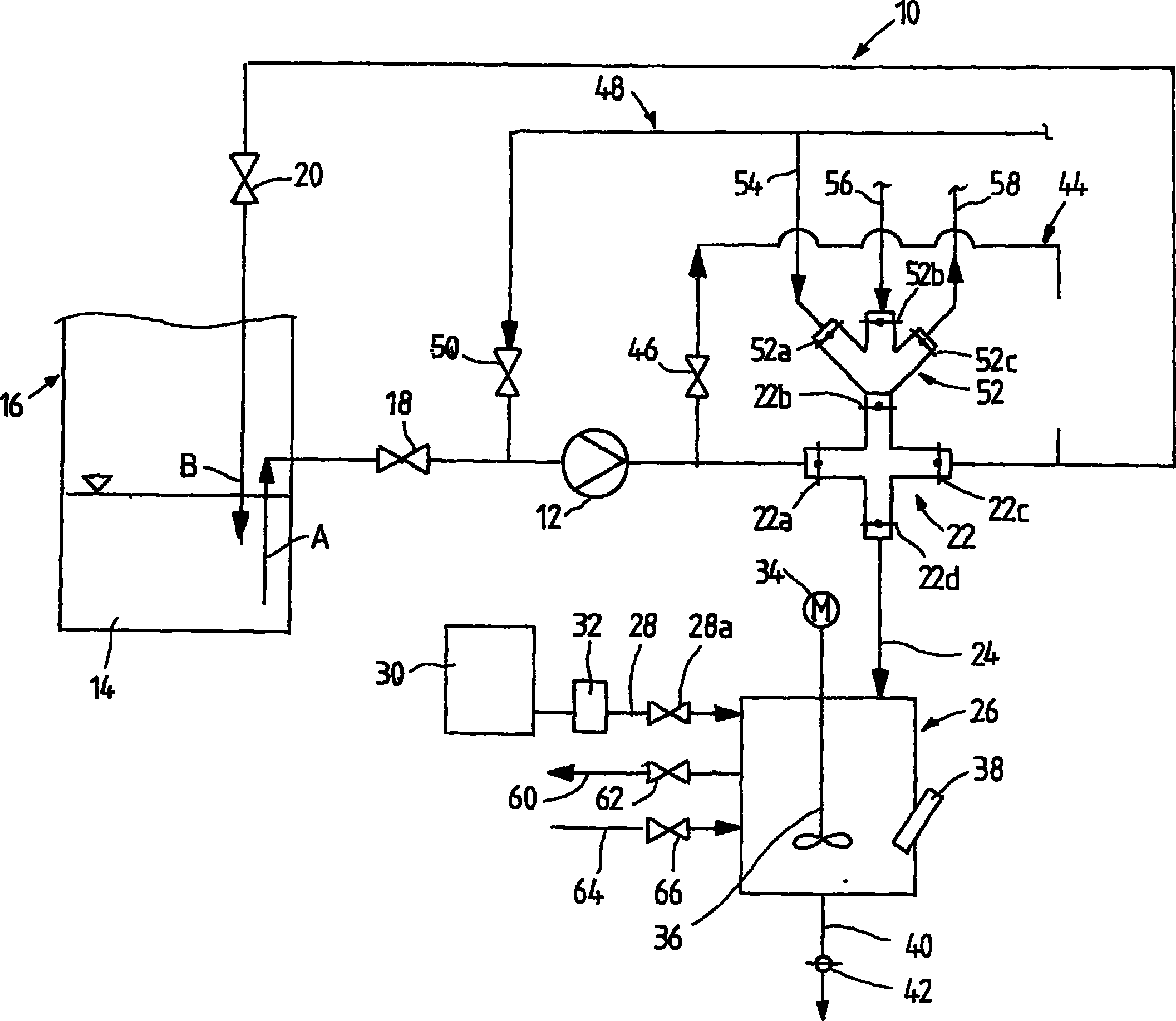

[0028] The shown arrangement comprises a closed loop line 10 through which washing liquid is pumped by means of a pump 12 from a washing liquid sump 14 of a washing column 16 which is only partially shown in the figure. Herein, the washing liquid that has been extracted from said washing liquid tank 14 is returned to said washing liquid tank 14 after flowing through closed circulation line 10, which is indicated by arrows A and B. The closed loop line 10 also includes throttle valves 18 and 20 which alternately allow or prevent passage of scrubbing liquid.

[0029] Downstream of said pump 12, a sample collector 22 is arranged in the closed circuit line, which allows a predetermined test volume of washing liquid to be separated from said closed circuit line. The sample collector 22 is connected by a tube 24 to a measuring cell 26 which can be fed into the test volume of washing liquid separated from said sample collector 22 . Furthermore, the pipe 28, which can be opened and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com