Rare earth-doped power battery anode material and preparation method thereof

A technology for power batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low electron transfer rate and ion diffusivity, polluting environmental raw materials, unsafe batteries, etc., to achieve accurate pH adjustment, avoid The effect of spreading and maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

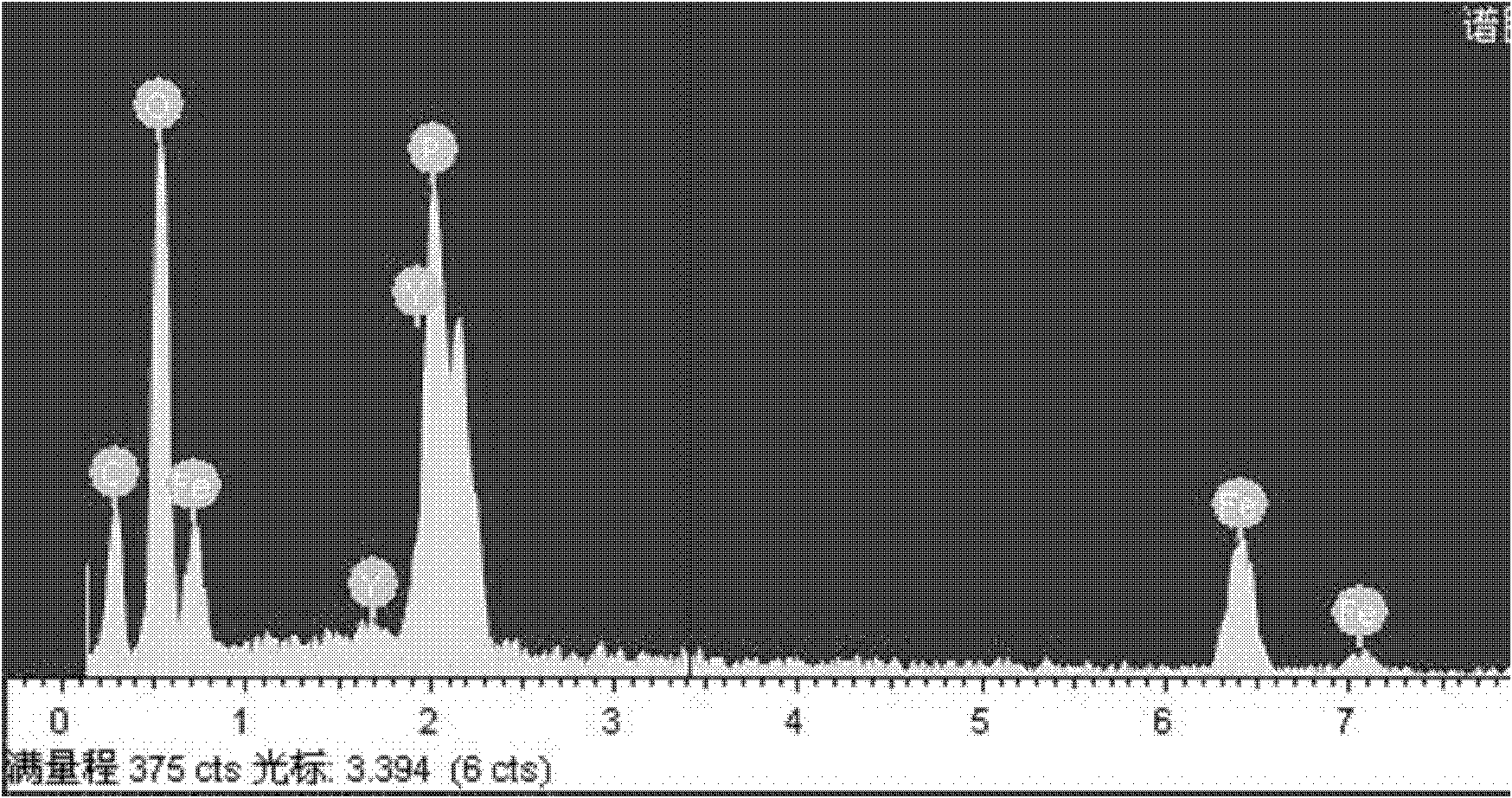

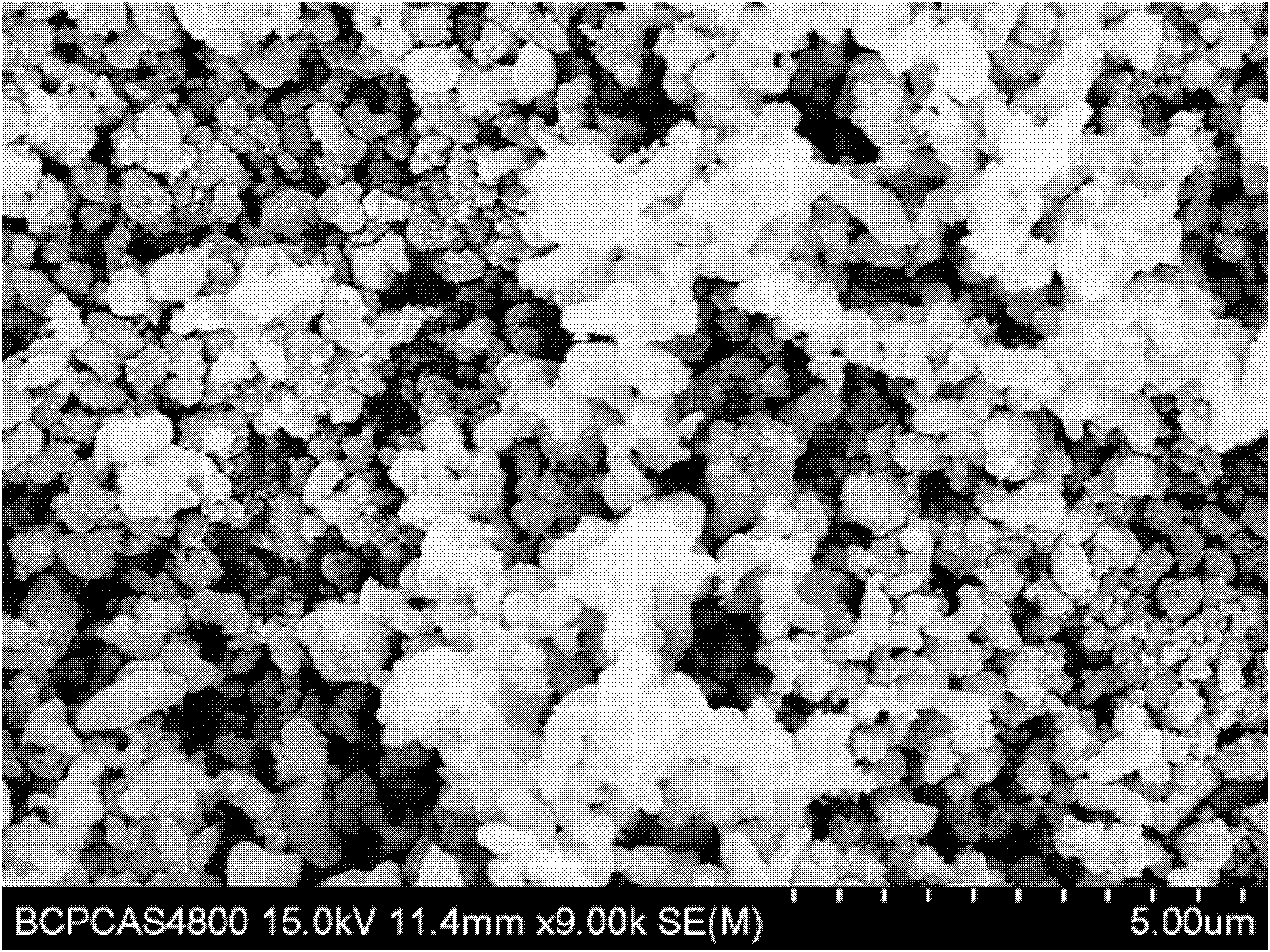

Image

Examples

Embodiment 1

[0032] 1) Mix 0.99mol LiCl, 0.99mol FeSO 4 ·7H 2 O, 1molH 3 PO 4 , 0.01mol LaCl 3 and 0.5mol urea were dissolved in 100g deionized water to obtain a uniform solution. When the solution was heated to 60°C in a water bath, the pH of the solution was adjusted to 5.0, and the solution was stirred rapidly for 10 hours and then suction filtered to obtain a precipitate. Wash it 4 times with deionized water ;

[0033] Then put the obtained precipitate into 1L of deionized water, stir rapidly for 1 hour to form a suspension, and then spray-dry the suspension at 180°C to collect the precursor;

[0034] 2) The precursor obtained by drying is filled with N 2 / H 2 Mixed gas (N 2 :H 2 =9: 1, volume ratio) in the tube furnace for sintering:

[0035] The heating rate is 3°C / min, when the temperature reaches 200°C, it is kept for 3 hours, and the flow rate of 100ml / min H 2 ; Then continue to heat up, when the temperature reaches 680 ° C, keep warm for 5 hours, then drop to room tempe...

Embodiment 2

[0037] 1) Mix 0.98mol LiBr, 0.98mol FeSO 4 ·7H 2 O, 1molH 3 PO 4 , 0.02mol YCl 3 and 0.5mol urea were dissolved in 100g deionized water to obtain a homogeneous solution, heated the solution to 60°C in a water bath, adjusted the pH of the solution to 7.0, stirred the solution rapidly for 10 hours and then filtered it with suction to obtain a precipitate and washed it 4 times with deionized water;

[0038] Then put the obtained precipitate into 1L of deionized water, stir rapidly for 1 h to form a suspension, and then spray dry at 200°C to collect the obtained precursor;

[0039] 2) The precursor obtained by drying is filled with N 2 / H 2 Mixed gas (N 2 :H 2 =3:1, volume ratio) in the tube furnace for sintering:

[0040] The heating rate is 3°C / min, when the temperature reaches 200°C, it is kept for 3 hours, and the flow rate of 100ml / min H 2 ; Then continue to heat up, when the temperature reaches 680 ° C, keep it warm for 16 hours, then drop to room temperature, and t...

Embodiment 3

[0043] 0.99mol Li 2 CO 3 , 0.99mol FeSO 4 ·7H 2 O, 1mol NH 4 h 2 PO 4 , 0.01mol CeCl 3 and 0.5mol urea were dissolved in 100g deionized water to obtain a homogeneous solution, heated the solution to 50°C in a water bath, adjusted the pH of the solution to 5.8, stirred the solution rapidly for 24 hours and then filtered it with suction to obtain a precipitate and washed it with deionized water 5 times;

[0044] Then put the obtained precipitate into 1L of deionized water, stir rapidly for 1 hour to obtain a suspension, and then freeze-dry at -20°C to collect the precursor;

[0045] 2) The precursor obtained by drying is filled with N 2 / H 2 =99:1 (volume ratio) for sintering in a tube furnace:

[0046] The heating rate is 3°C / min. When the temperature reaches 220°C, keep it warm for 5 hours, and then continue to heat up. When the temperature is below 20-280°C, the flow rate of 150ml / min H 2 ;When the temperature reaches 750°C, keep it warm for 5h, then drop to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com