Diffusion impact type fine atomizer nozzle

A technology of fine water mist and nozzles, which is applied in spraying devices, spraying devices, fire rescue, etc., can solve the problems of low relative momentum and achieve the effects of wide adaptability, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

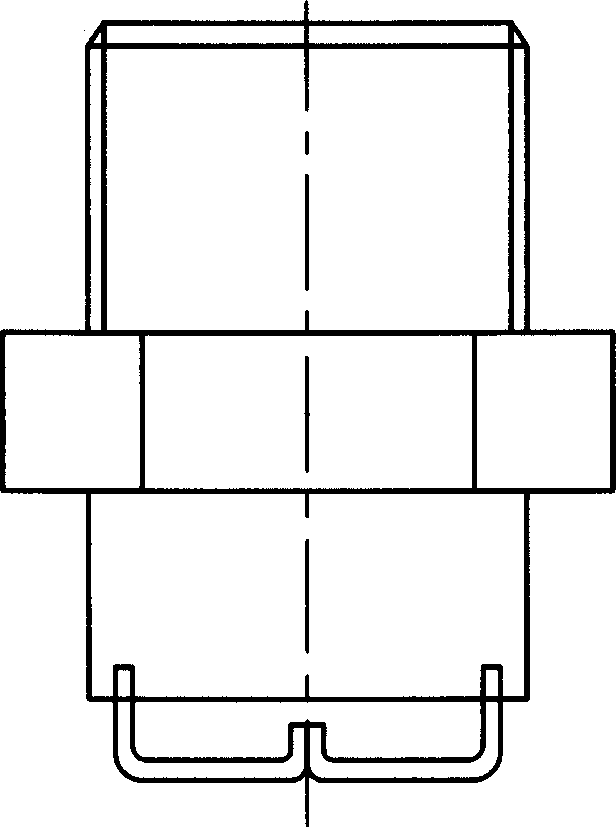

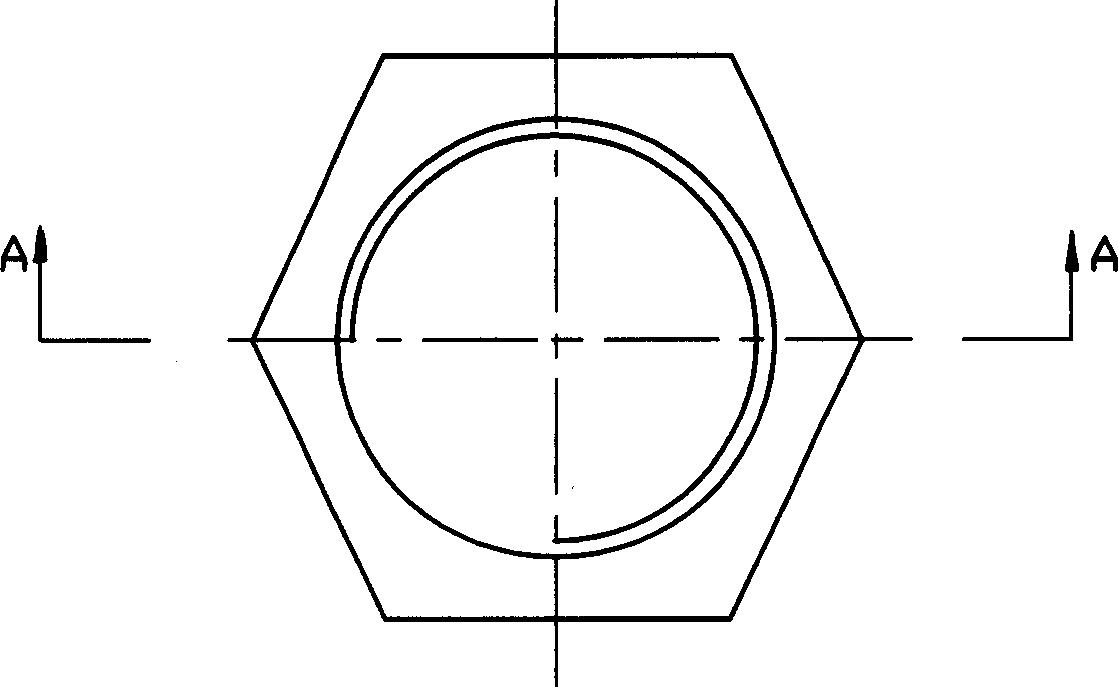

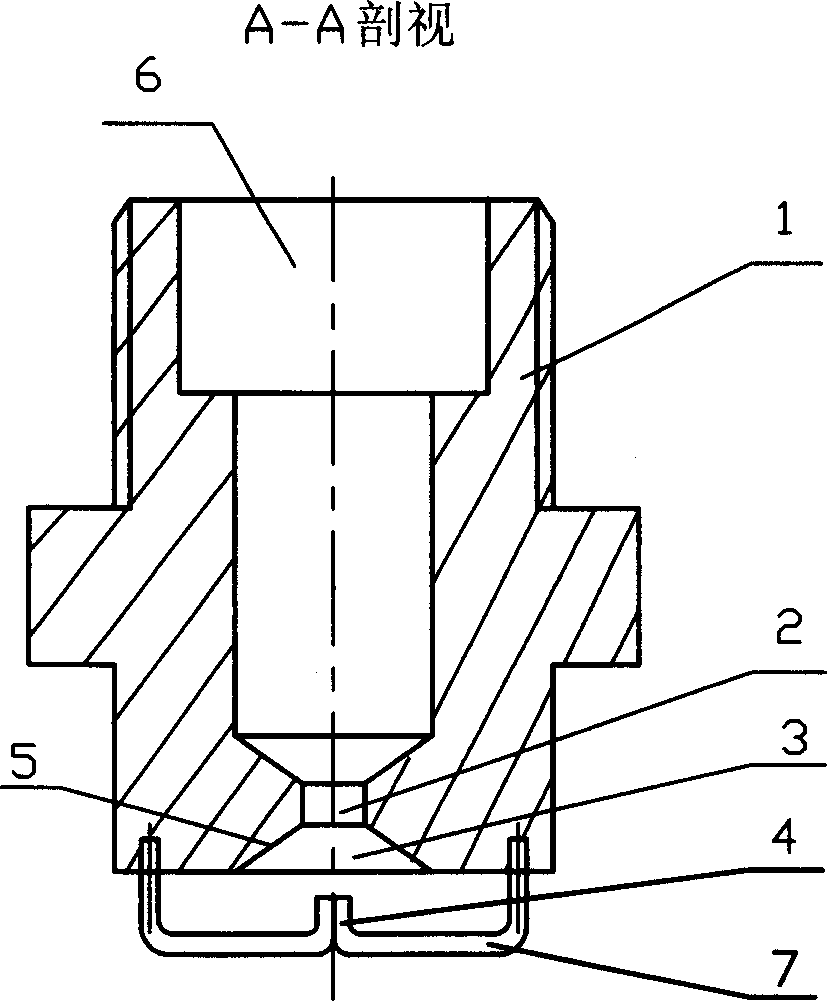

[0028] The diffusion impact type fine water mist nozzle of embodiment 1, as Figure 4 As shown, the diffuser is composed of three firing pins, the firing pins are cylindrical, the angle of the conical slope of the water outlet is 60°, the diameter of the small hole is φ2, and the distance between the highest position of the diffuser’s impact surface and the small hole outlet is 1.5mm.

Embodiment 2

[0029] The diffusion impact type fine water mist nozzle of embodiment 2, as Figure 5 As shown, the diffuser is composed of four firing pins, the firing pins are cylindrical, the angle of the conical slope of the water outlet is 90°, the diameter of the small hole is φ3, and the distance between the highest position of the diffuser’s impact surface and the small hole outlet is 2mm.

Embodiment 3

[0030] The diffusion impact type fine water mist nozzle of embodiment 3, as Image 6 As shown, the diffuser is composed of five firing pins, the firing pins are cylindrical, the angle of the conical slope of the water outlet is 120°, the diameter of the small hole is φ3.3, and the distance between the highest position of the impact surface of the diffuser and the small hole outlet 2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com