Cylinder oblique arranged planetary barrel polisher driven by synchronous belt

A synchronous belt drive, planetary roller technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc. Adjustment and other problems to achieve the effect of improving polishing effect, reasonable structure and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

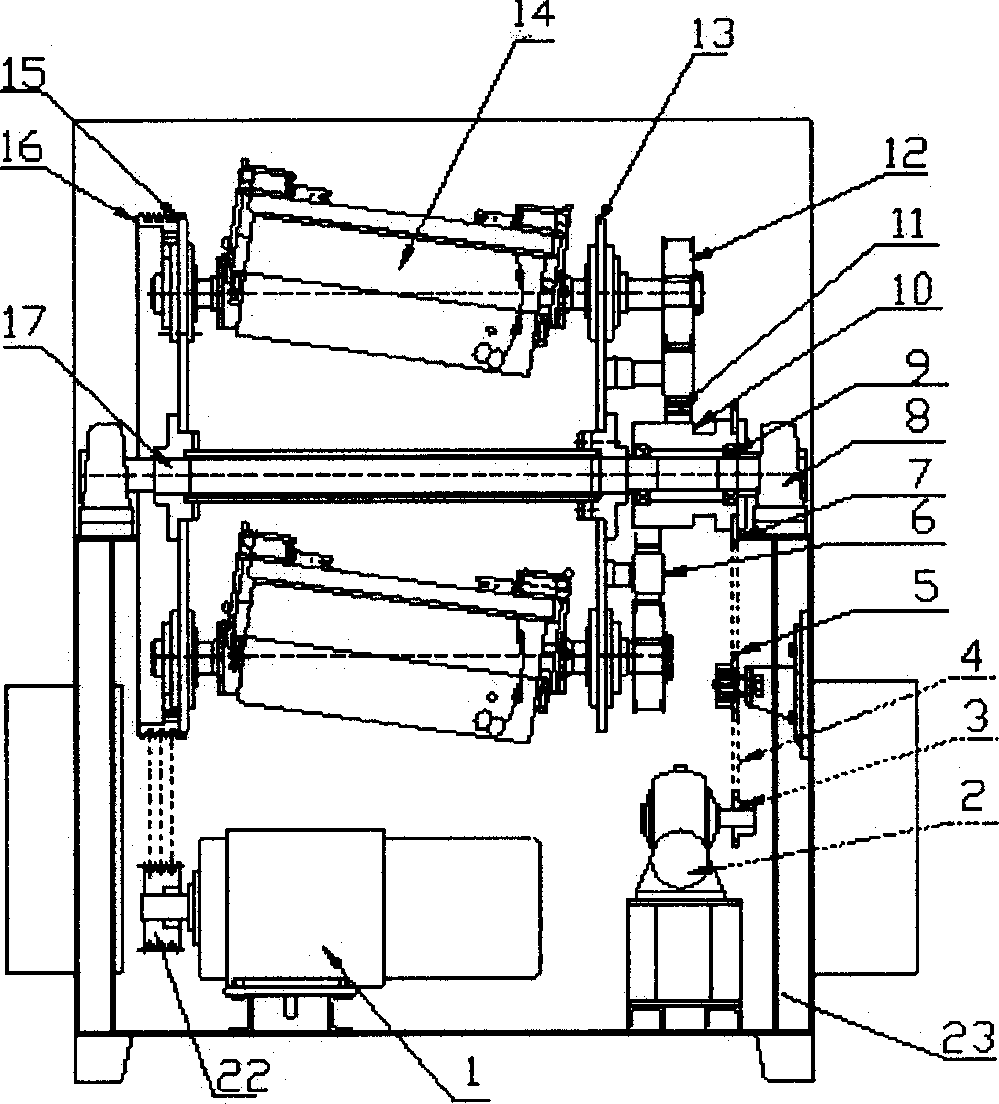

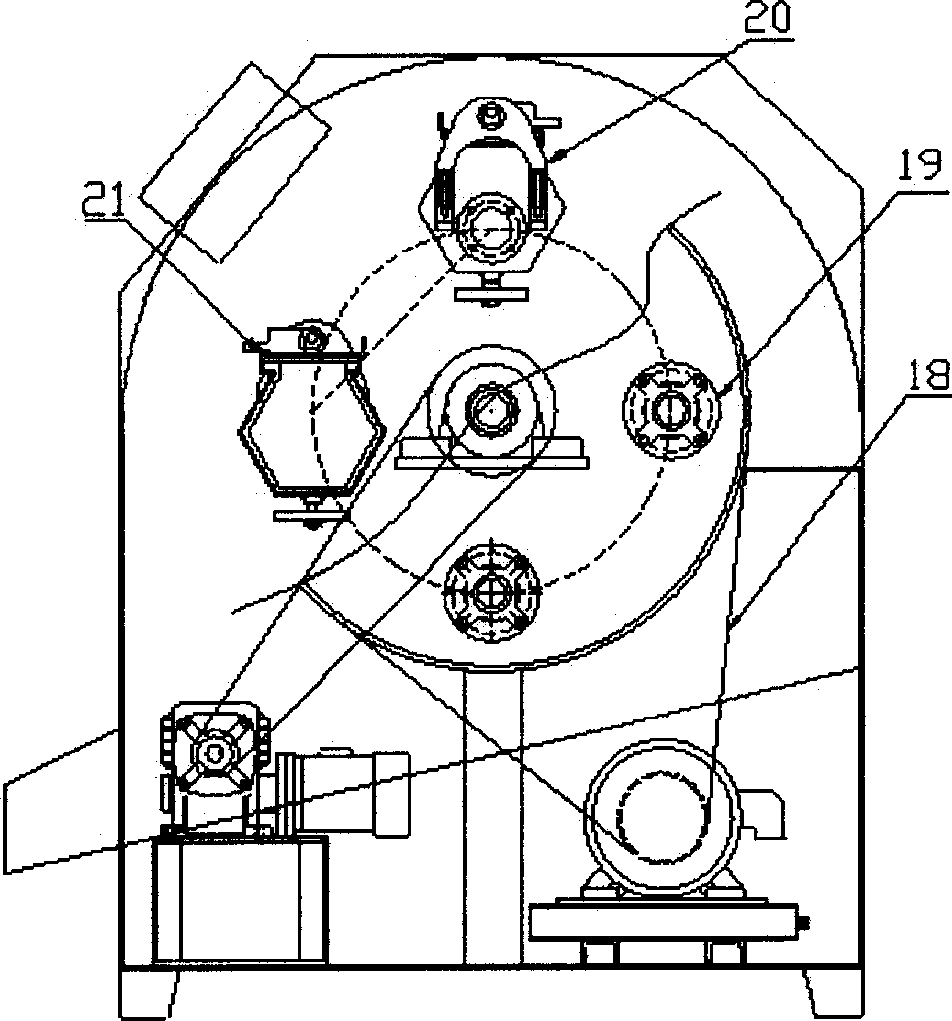

[0027] Embodiment of the present invention: the main motor 1 selects the electromagnetic brake motor YET132M 1 -6-4.0, and equipped with a frequency converter, the worm gear reducer 2 has a jogging function; the synchronous belt 11 is an arc-toothed synchronous belt, and the roller 14 is made of 4 circular sections and 4 hexagonal sections. The volume of each drum 14 is 15 liters. The cross-sectional shape of the drum is selected according to the requirements of the workpiece. For workpieces that require high surface quality and do not allow indentations, choose circular ones. For workpieces that are not easy to produce indentations when colliding Choose a hexagon, and the angle α between the geometric axis of the drum 14 and the axis of rotation is 8°; make the main shaft 17, the frame 23 and all other parts, and assemble them as follows according to the requirements of the attached drawings:

[0028] First, load onto the left wheel disc 15, the right wheel disc 13, the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com