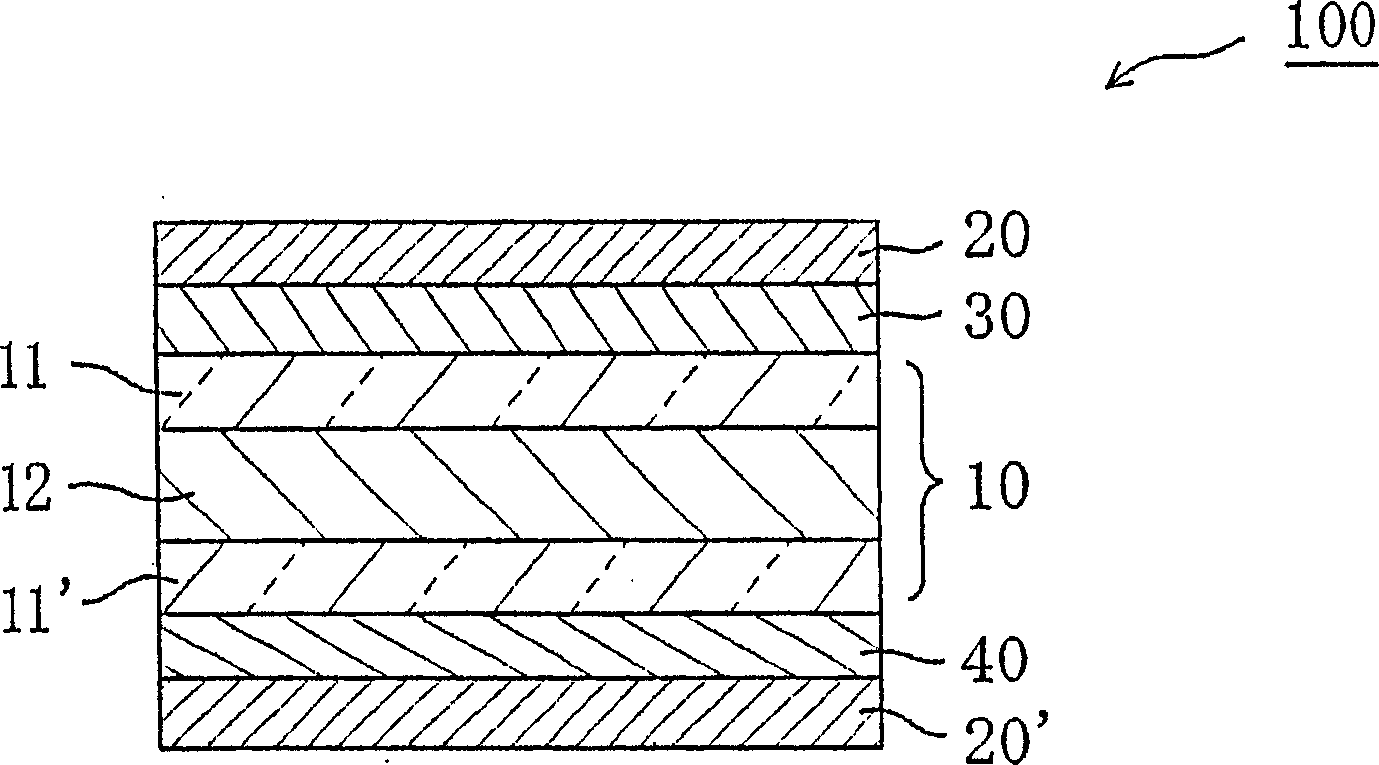

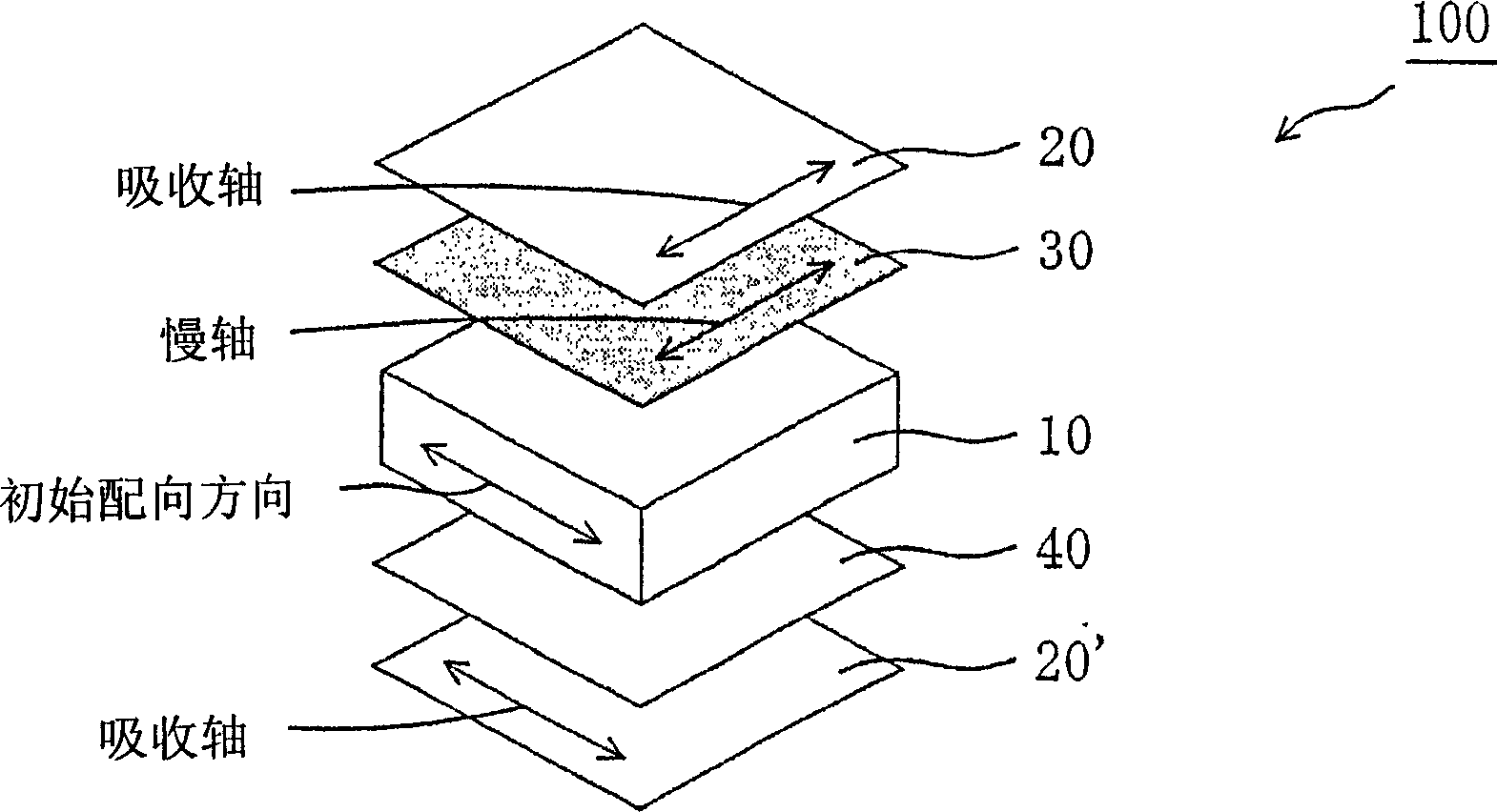

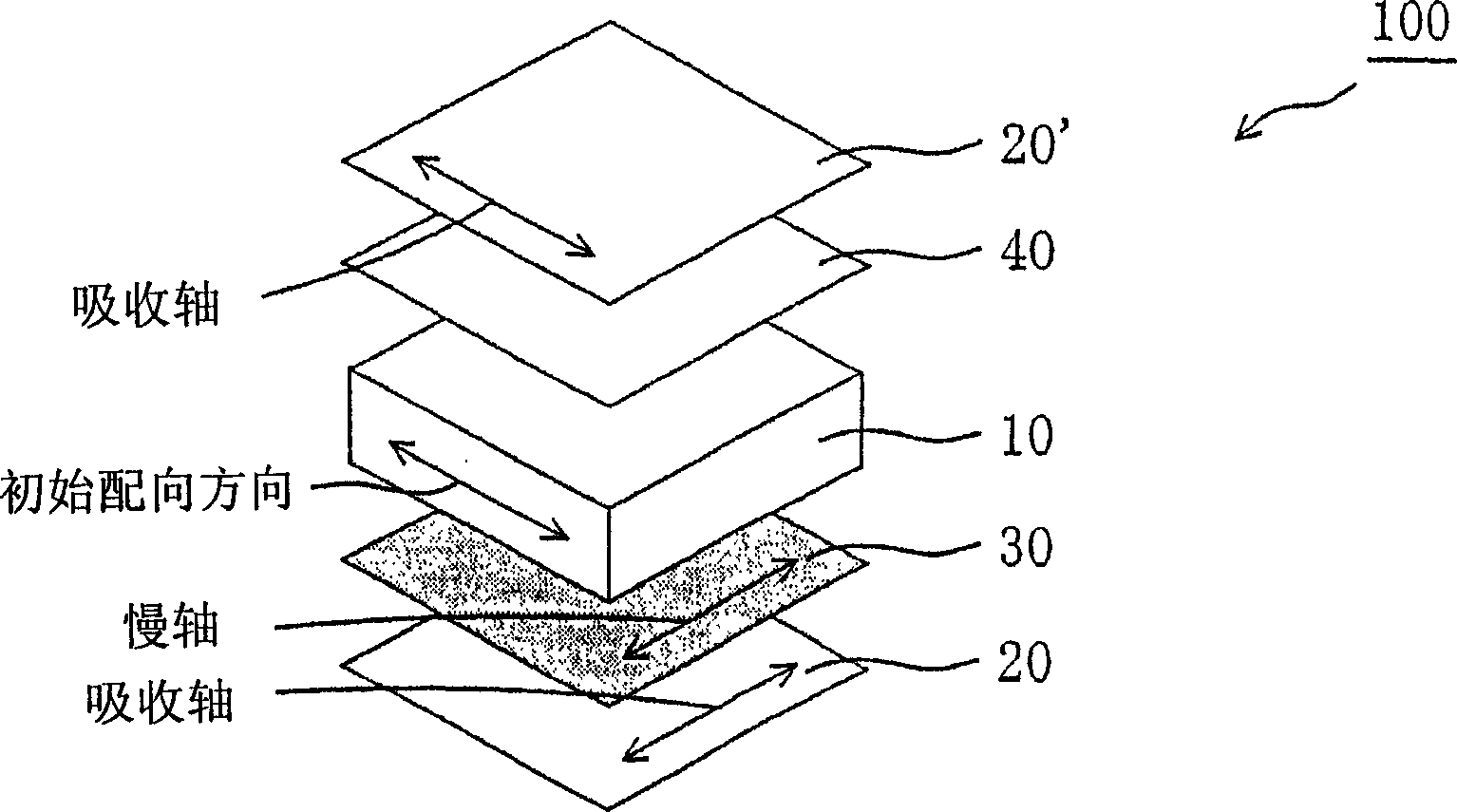

Liquid crystal panel and liquid crystal display apparatus

A liquid crystal panel and liquid crystal unit technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of uneven phase difference, unobtained phase difference film, film rupture, etc., to prevent unevenness and long-term display performance The effect of maintaining and enhancing contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0256] A biaxially stretched polypropylene film "TORAYFAN B02873" (trade name, thickness 60 μm, available from Toray Industrial Co., Ltd.) having the properties shown in Table 1 was passed through an acrylic pressure-sensitive adhesive layer (thickness 15 μm). ) was attached to both sides of a norbornene-based resin film "ZEONORZF14-100" (trade name, thickness 100 µm, available from Zeon Corporation). Then, using a roll stretching machine, the resulting product was stretched 1.38 times in an air-circulating constant temperature heating furnace at 146° C. (the temperature at a distance of 3 cm from the rear surface of the film, temperature fluctuation ± 1° C.), while fixing the thickness of the film. longitudinal direction, thereby manufacturing retardation film A. Table 2 shows the properties of the obtained retardation film. The norbornene-based film had a glass transition temperature (Tg) of 136° C., an internal retardation value of 5.0 nm before stretching, and a retardati...

preparation Embodiment 2

[0260] Retardation film B was manufactured in the same manner as in Preparation Example 1, except that the stretching temperature was changed from 146° C. to 148° C., and the draw ratio was changed from 1.38 times to 1.40 times. Table 2 shows the stretching conditions and properties of the obtained retardation film B.

preparation Embodiment 3

[0262] Retardation film C was produced in the same manner as in Example 1, except that the stretching temperature was changed from 146° C. to 148° C., and the draw ratio was changed from 1.38 times to 1.35 times. Table 2 shows the stretching conditions and properties of the obtained retardation film C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stretch temperature | aaaaa | aaaaa |

| Stretch temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com