Grid control signal generation apparatus and method for liquid crystal display

A liquid crystal display, gate control technology, applied to static indicators, instruments, etc., to achieve the effect of reducing the number of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

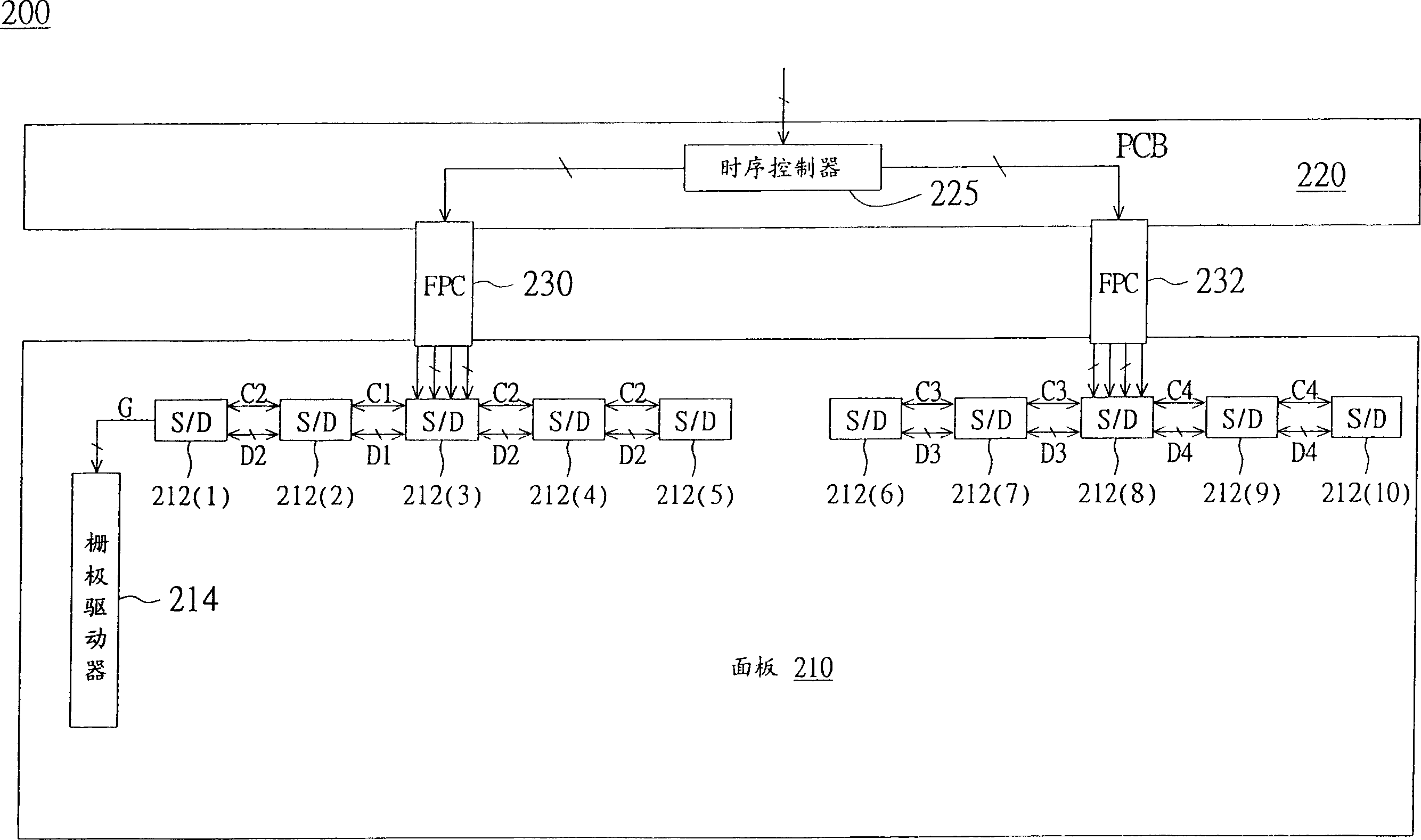

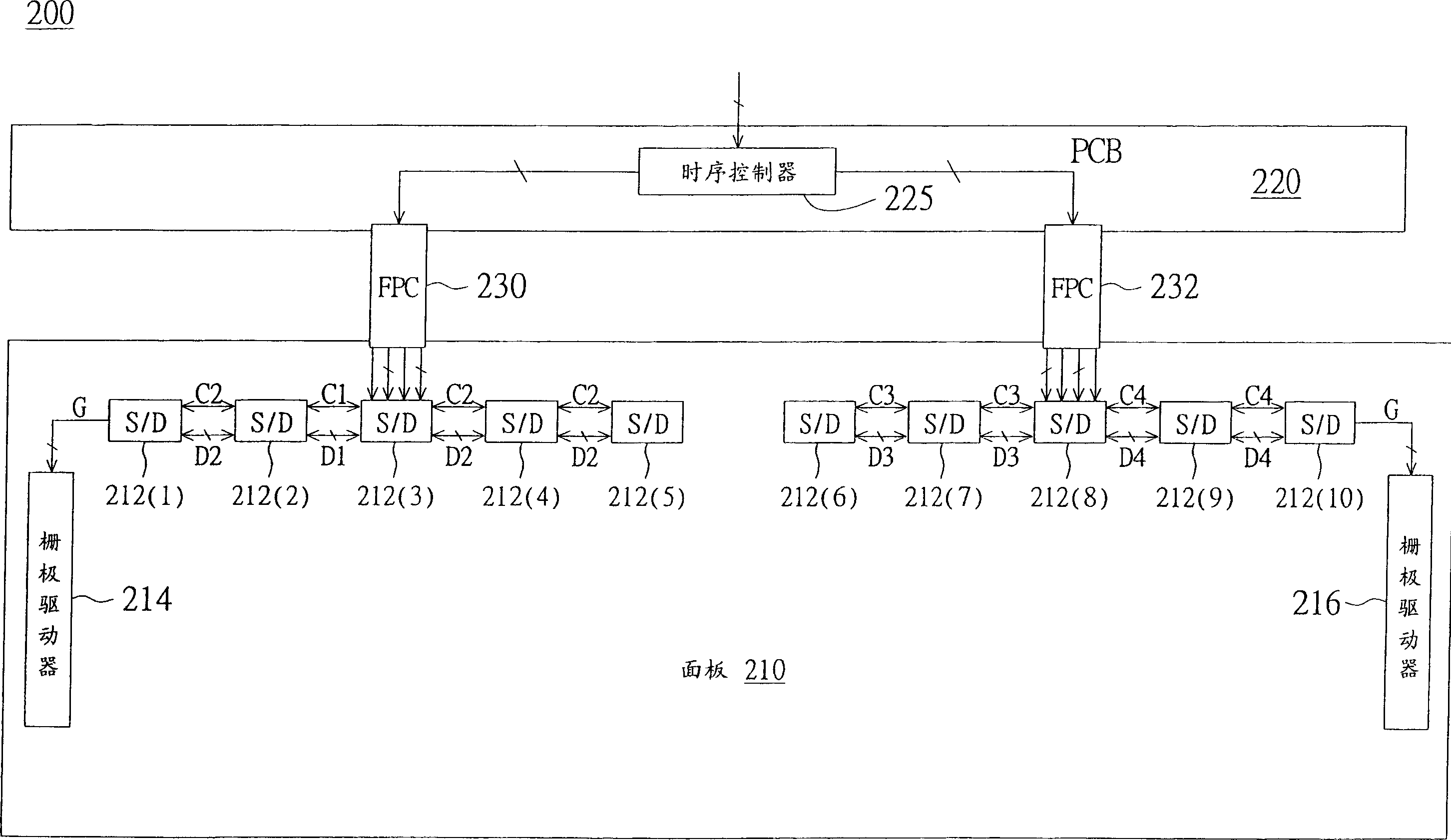

[0050] Please refer to Figure 2A , which shows a schematic diagram of a liquid crystal display using Chip On Glass (COG) package according to a preferred embodiment of the present invention. The liquid crystal display 200 includes: a panel 210, a plurality of source drivers (Source Driver, S / D) 212(1)-211(10), at least one gate driver (Gate Driver) 214, a printed circuit board 220 and a flexible circuit board 230 and 232. The source driver 212 and the gate driver 214 are disposed on the glass substrate of the panel 210 . The timing controller 225 is arranged on the printed circuit board 220 to receive image data and control signals, and then transmit them to the source drivers 212(3) and 212(8) through flexible circuit boards (FPC) 230 and 232 after processing. The source drivers 212(3) and 212(8) respectively transmit the received image data and source control signals to the adjacent source drivers 212(1), 212(2), 212(4) through the wires on the glass substrate. ), 212(5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com