Multi-roller steel plate-flattening machine

A technology of straightening machine and steel plate, which is applied in the field of key finishing equipment---steel plate multi-roll straightening machine, can solve the problems of difficult steel plate thickness straightening accuracy requirements and large size, and achieve the effect of large thickness range, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation will be described below in conjunction with the accompanying drawings.

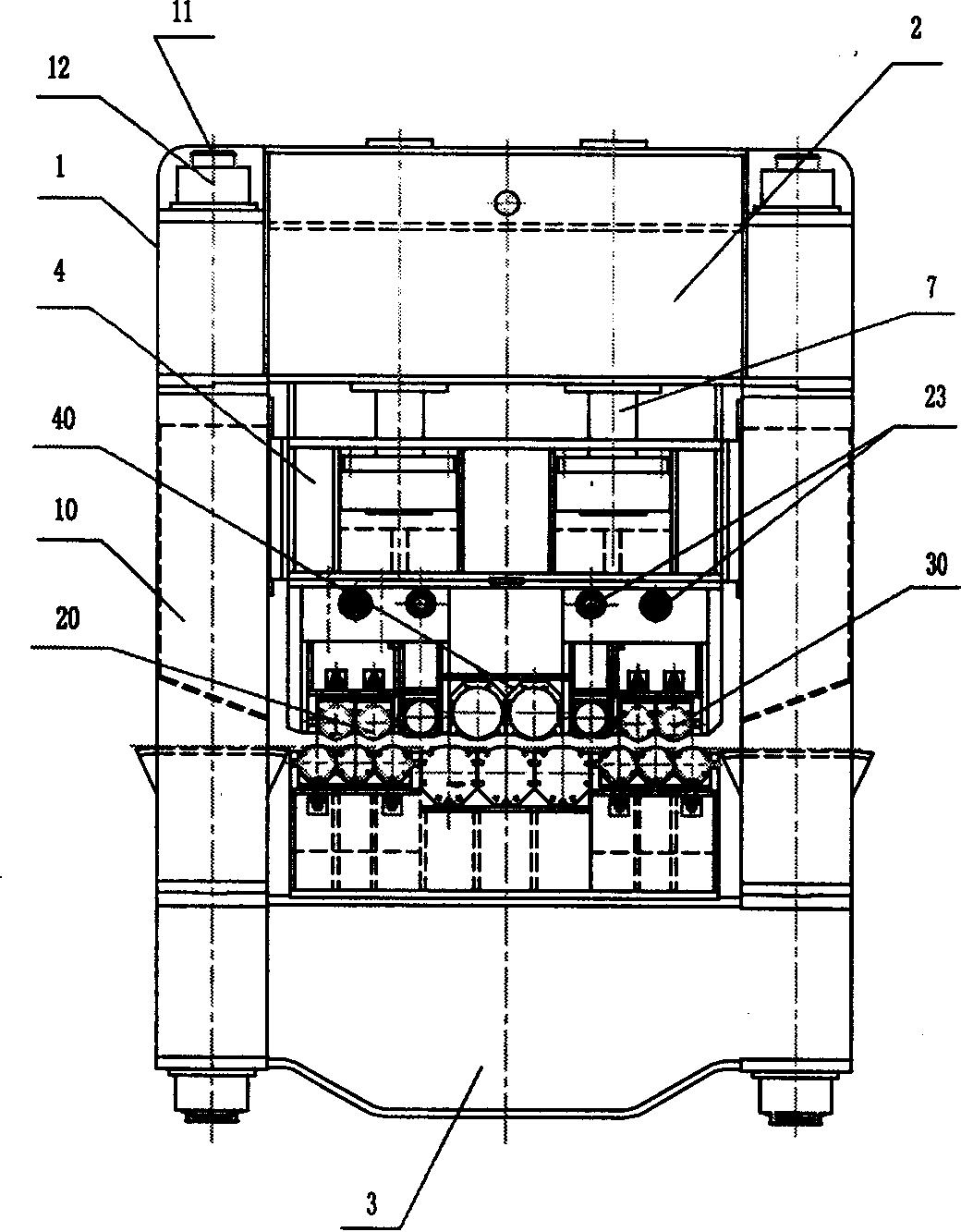

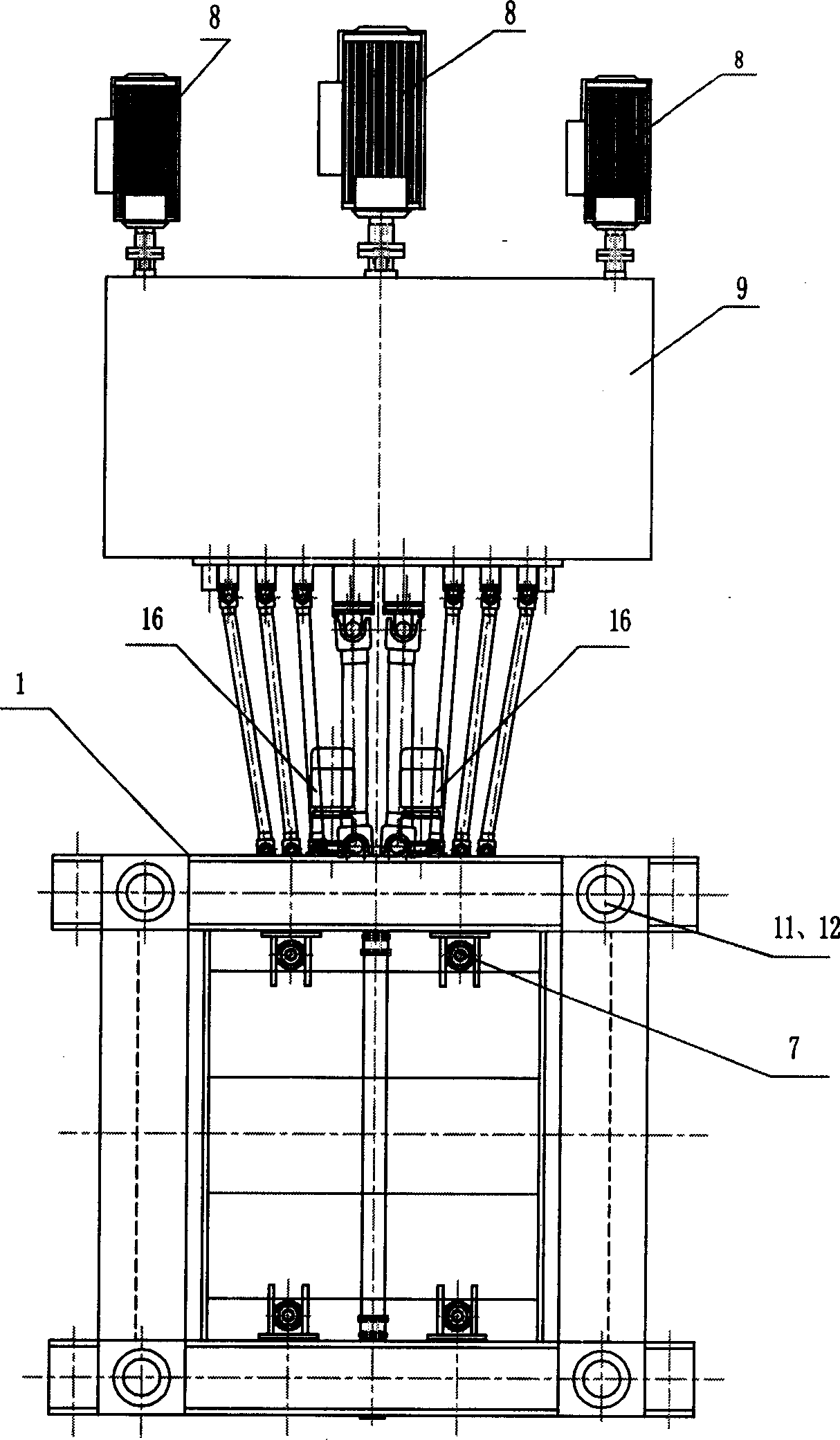

[0022] figure 1 and figure 2 Shown, be the steel plate multi-roll leveling machine of the seventeen rolls of concrete design of the present invention. It includes a frame 1, an upper beam 2, a lower beam 3, a movable beam 4, a work roll 5 and a support roll 6 device set on the movable beam and the lower beam, and a pressing mechanism 7 on the movable beam and the frame. As shown, the working Roller drive motor 8, reducer 9, etc. Frame is made of column 10, preloaded screw rod 11, nut 12, and upper beam and lower beam.

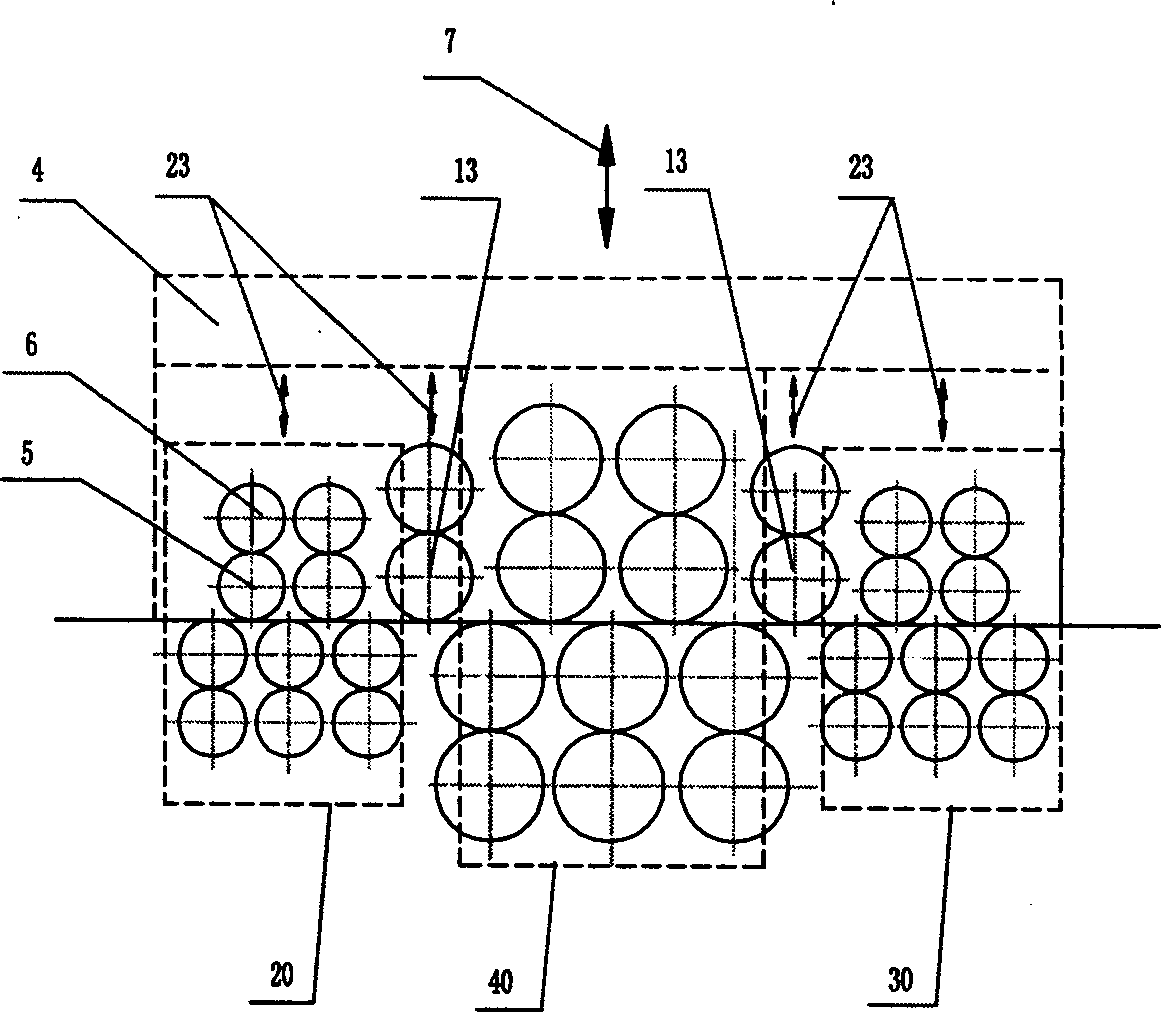

[0023] image 3 As shown, the distribution diagram of the straightening rolls of the seventeen-roll steel plate multi-roll straightening machine. The work roll and back-up roll device is divided into three parts, namely the inlet part 20, the outlet part 30, and the middle part 40; the three parts are installed under the movable beam; The mechanism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com