Equilibrium reactions and gas/liquid reaction in a loop reactor

A loop reactor and reactor technology, applied in the chemical method of reacting liquid and gas medium, chemical/physical/physical chemical fixed reactor, chemical/physical/physical chemical nozzle reactor, etc., can solve Expensive and complicated equipment and process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

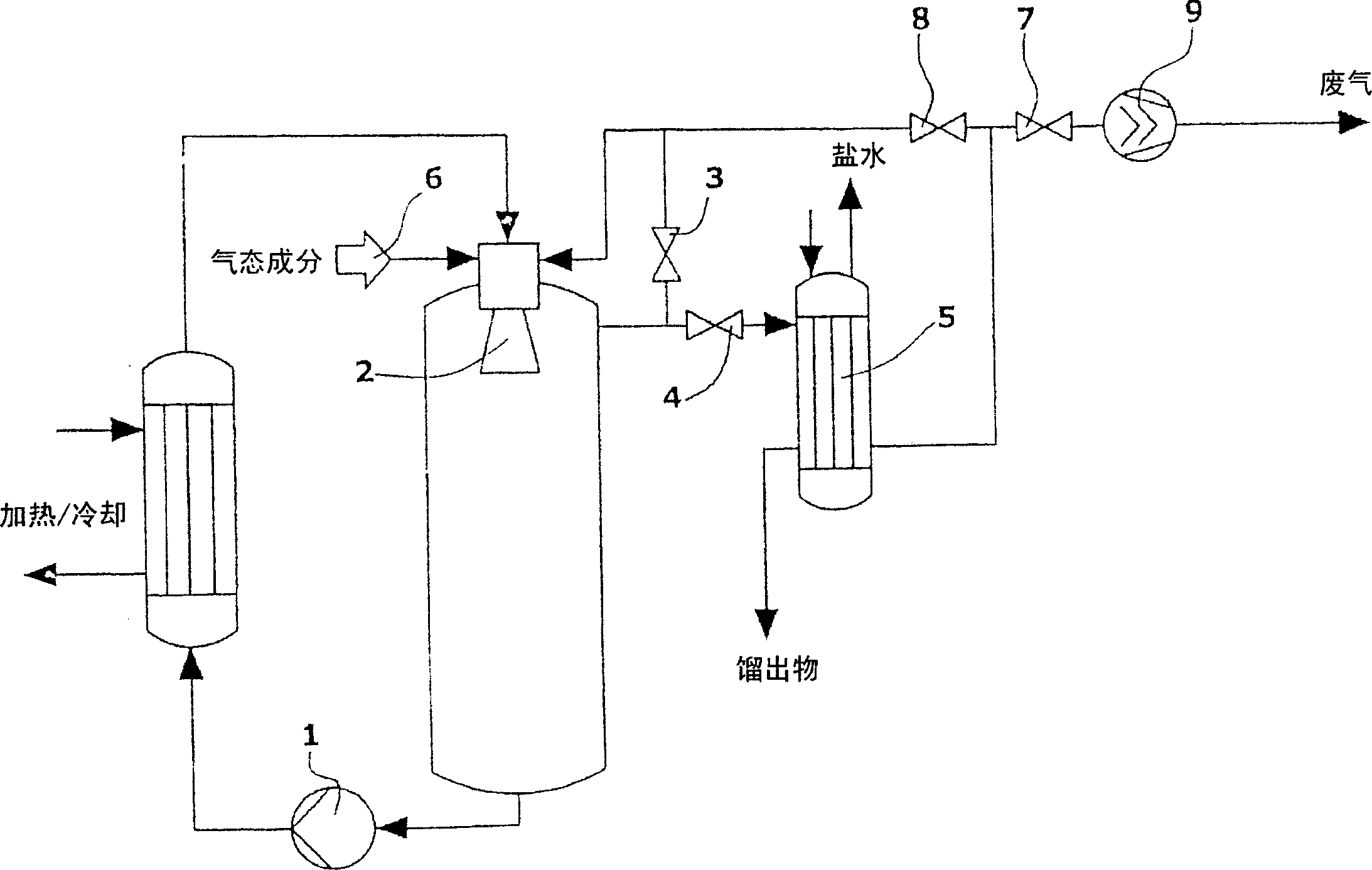

[0061] with a loop reactor of capacity 501 figure 1 In the plant shown, initially 40 kg of high boiling polyether alcohol were charged into the reactor. The polyether alcohols used are alkenyl-started polyethers of the form,

[0062] R 1 -(OC 2 h 3 Me) n -(OC 2 h 4 ) m -OH

[0063] in

[0064] R 1 is an alkenyl group having 3 carbon atoms,

[0065] n is 13 and m is 4.

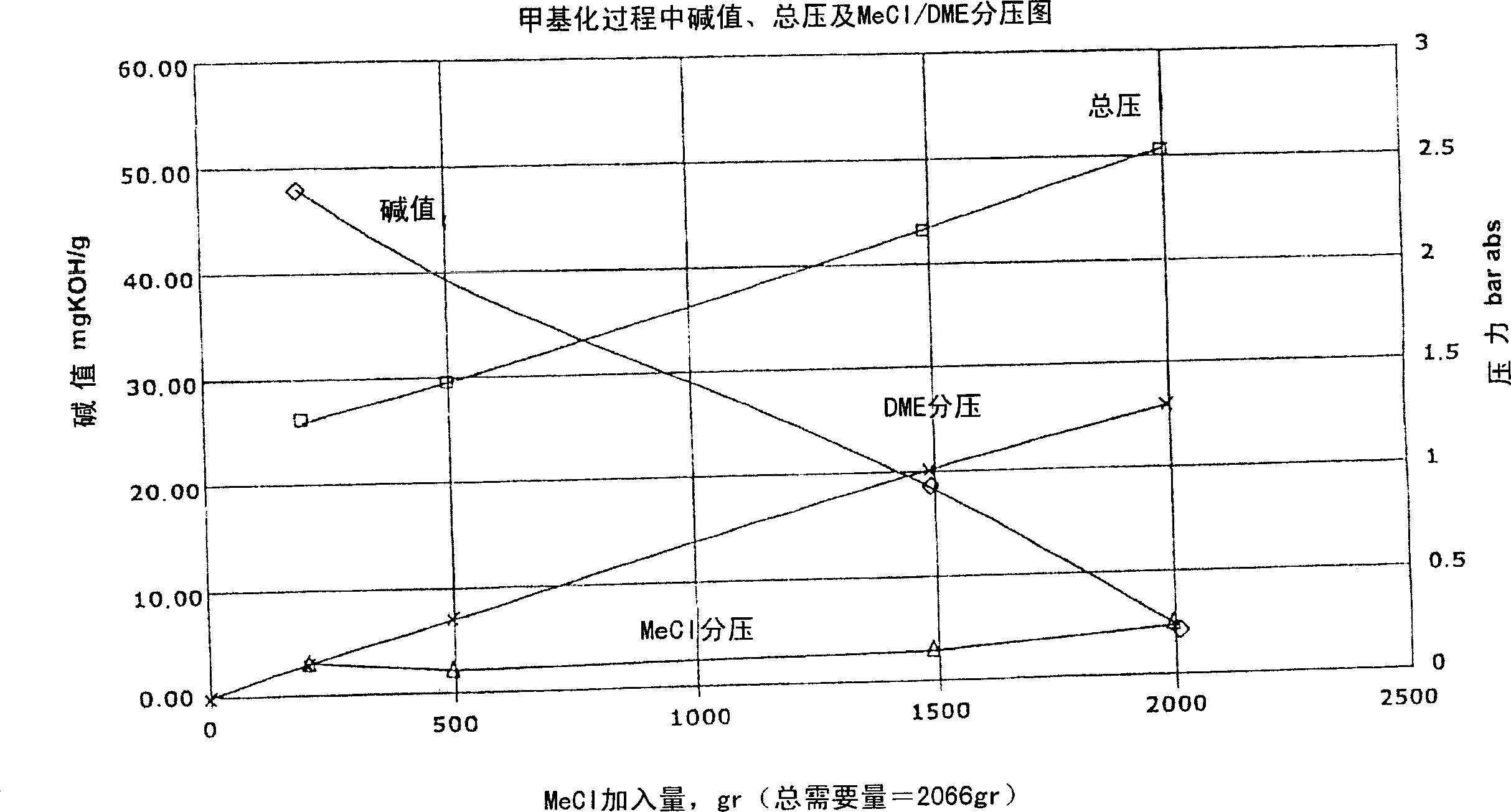

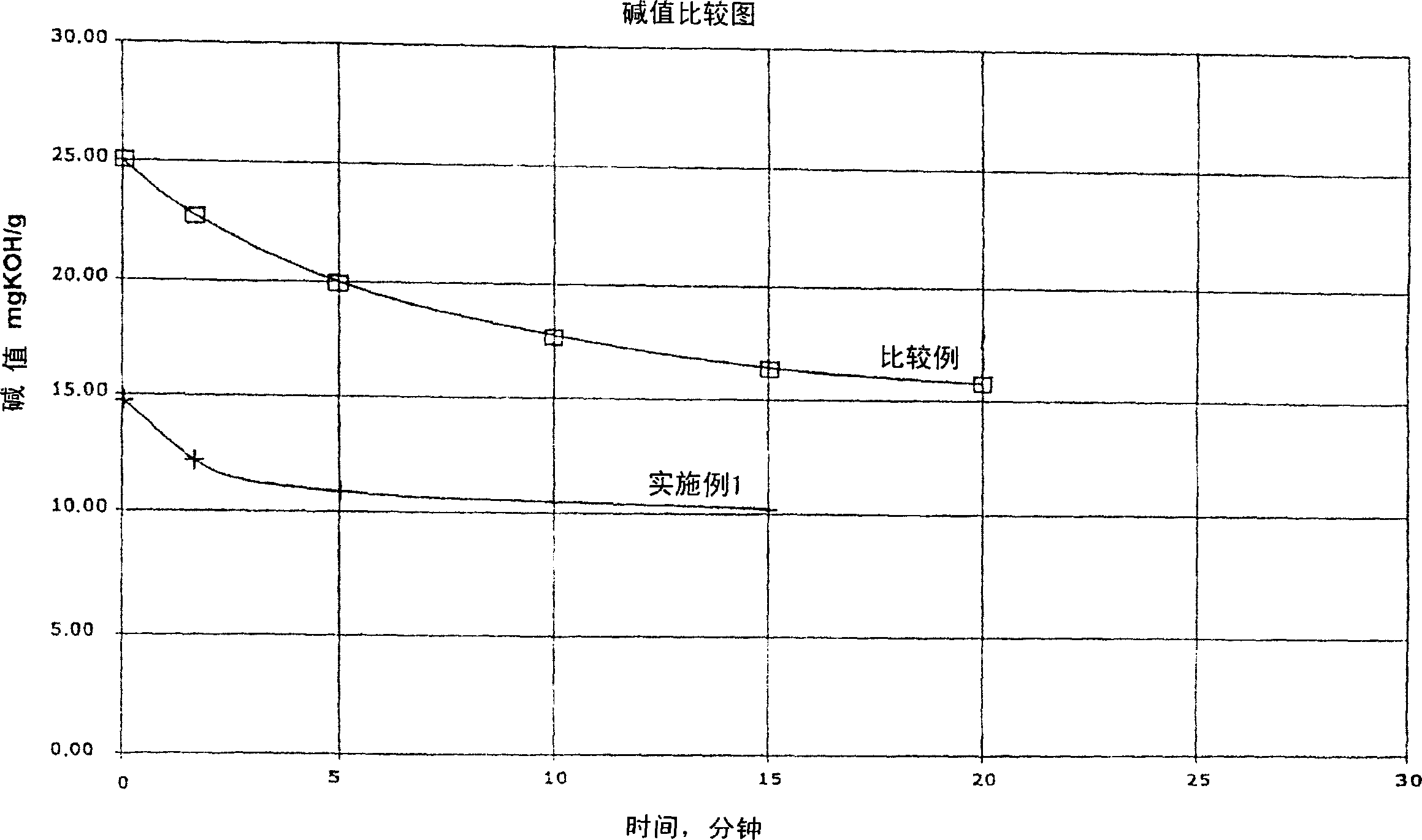

[0066] Then measure 15 kg of 30% sodium methoxide methanol solution into the polyether alcohol in the reactor. In the closed condensation loop with valve 3 closed and valve 4 open, the reactants react at 110°C according to equilibrium reaction I, during which methanol is condensed down in condenser 5 until it reaches the condensation temperature of -15°C (initial stage). The partial pressure of methanol in the gas phase was determined from the condensation temperature and the residual methanol content in the liquid phase was determined by phase equilibrium, which corresponds to the poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com