Safe ultrasonic cleaning machine with inflammable cleaning agent

A cleaning machine, ultrasonic technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of lack of safety hazards, failure to install flame retardant and explosion suppression devices, failure to deal with automatic fire extinguishing devices, etc. , to achieve the effect of low cleaning cost, high cleaning efficiency and low equipment operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

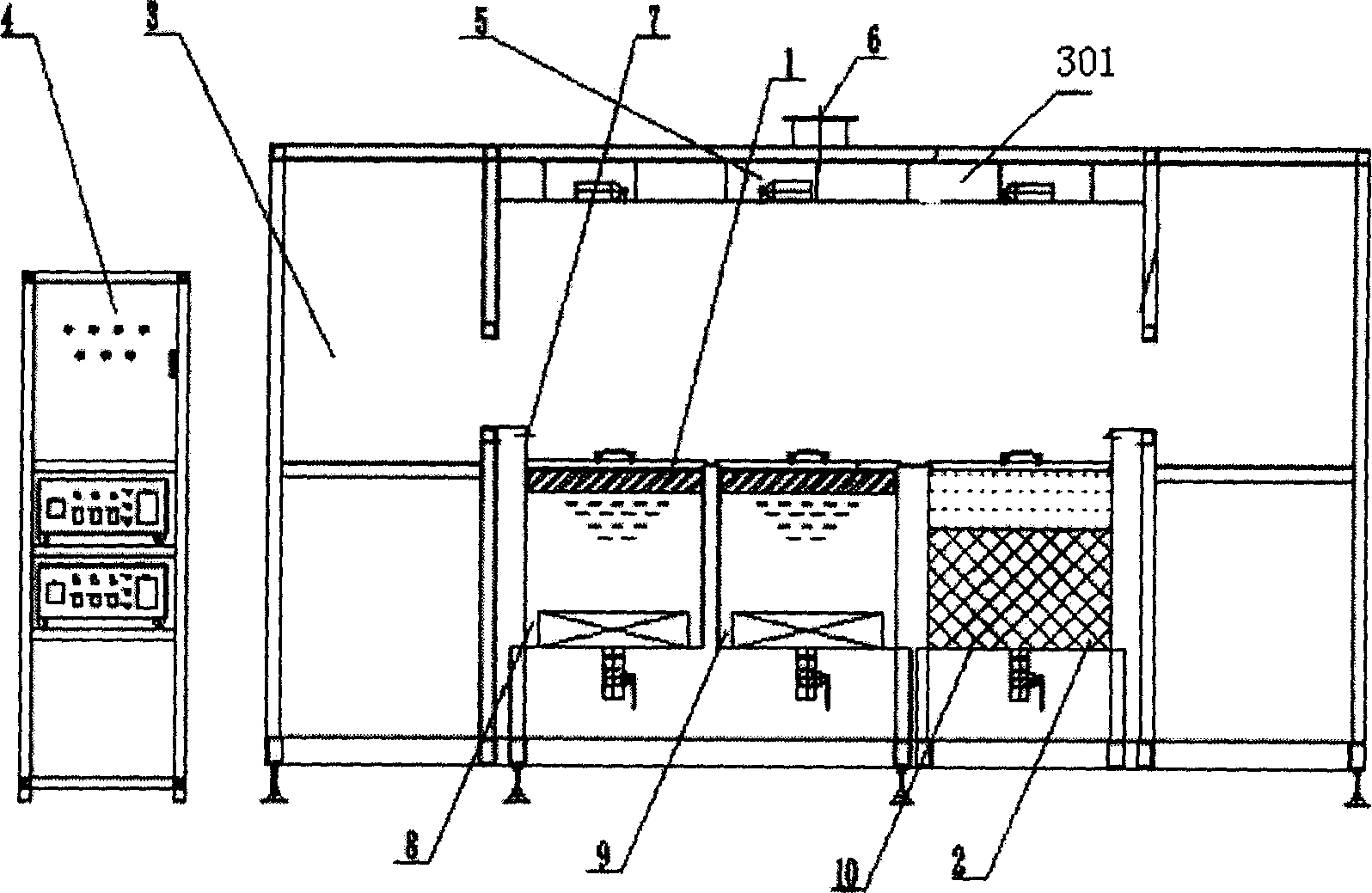

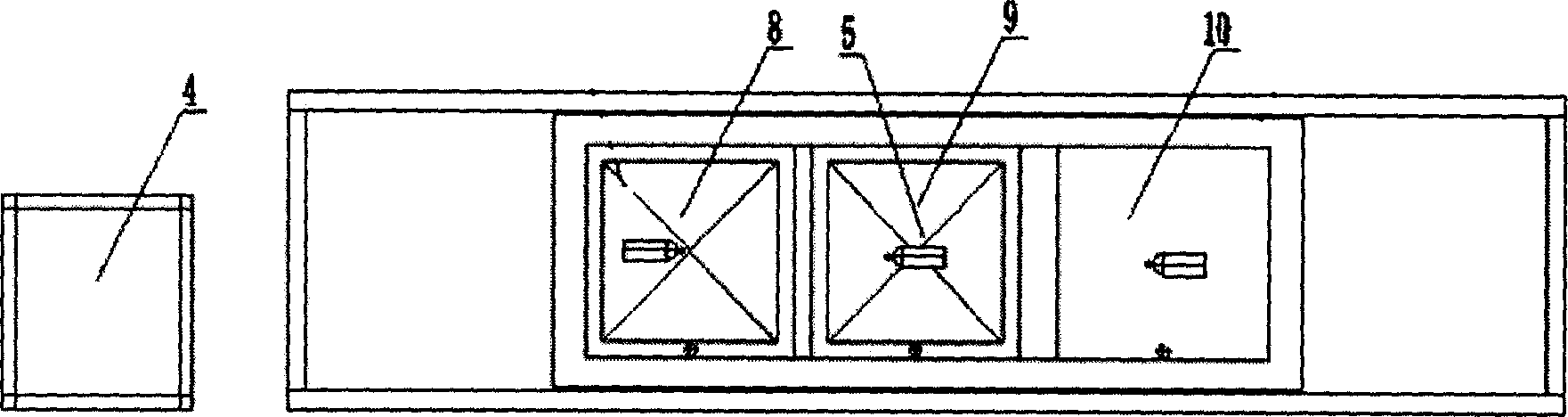

[0022] The present invention is further elaborated below in conjunction with accompanying drawing and embodiment:

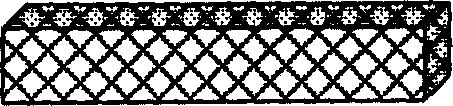

[0023] Such as figure 1 As shown, a safe ultrasonic cleaning machine using a flammable cleaning agent includes a main body 3, an electric control device 4, two ultrasonic cleaning tanks 8 in the main body 3, a steam cleaning tank 10 and a condensation device 301 on the top . The flame retardant and explosion suppression plate 1 is about 2mm away from the inner tank wall, and has a thickness of 80mm.

[0024] When using ultrasonic cleaning tank (1) 8 to ultrasonically clean the object, first immerse the cleaning basket containing the object in the cleaning agent, then cover the cleaning basket with the flame-retardant explosion suppression plate 1, place it on the liquid surface of the cleaning agent, and then start ultrasonic After cleaning, take out the flame-retardant and explosion-suppressing plate 1, and then take out the cleaning basket.

[0025] When usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com