Refrigeration device

A refrigeration device and refrigerant technology, which is used in household refrigeration devices, refrigerators, refrigeration components, etc., to achieve the effects of improving the refrigeration coefficient, improving performance, and reducing compression power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

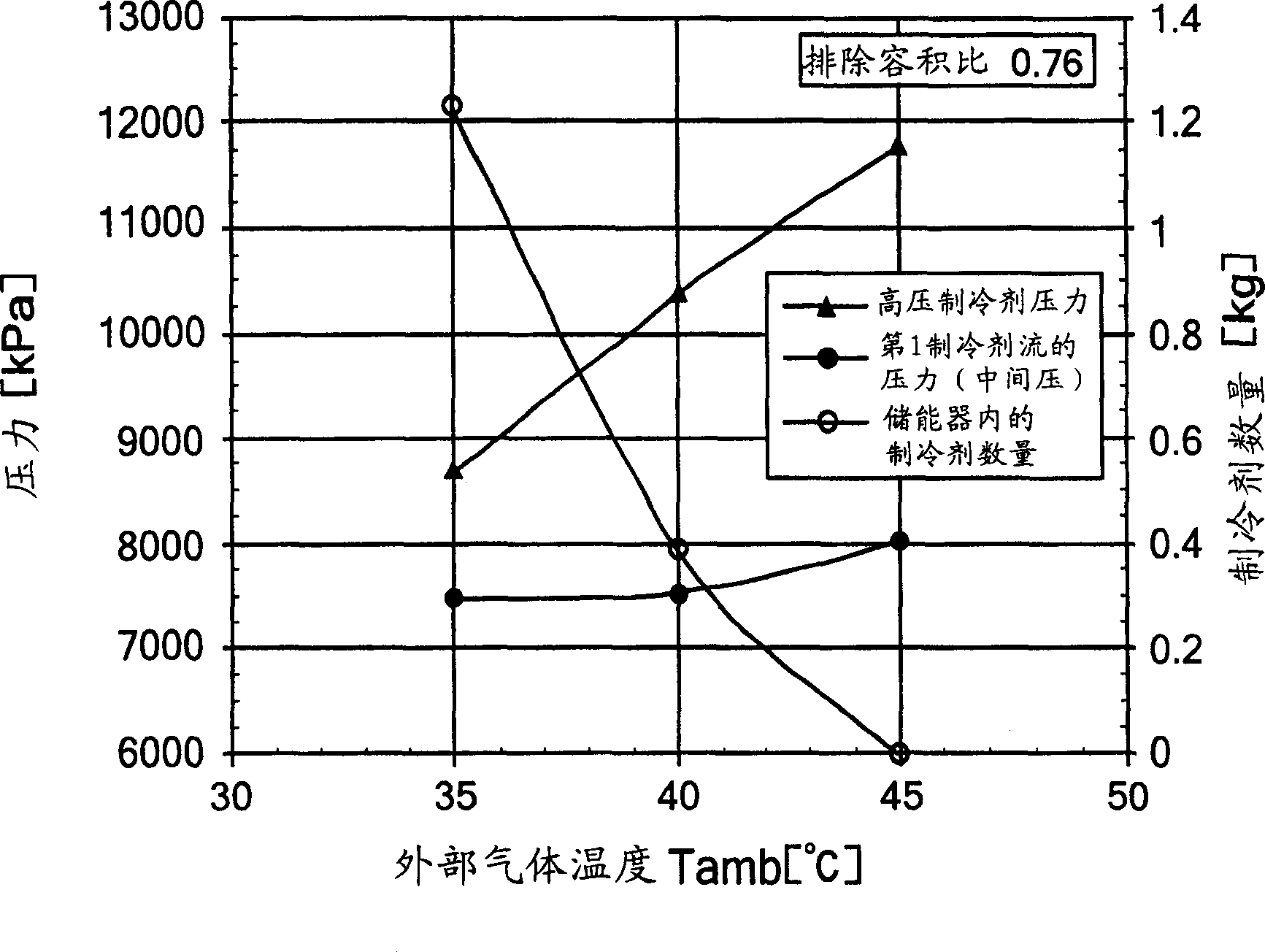

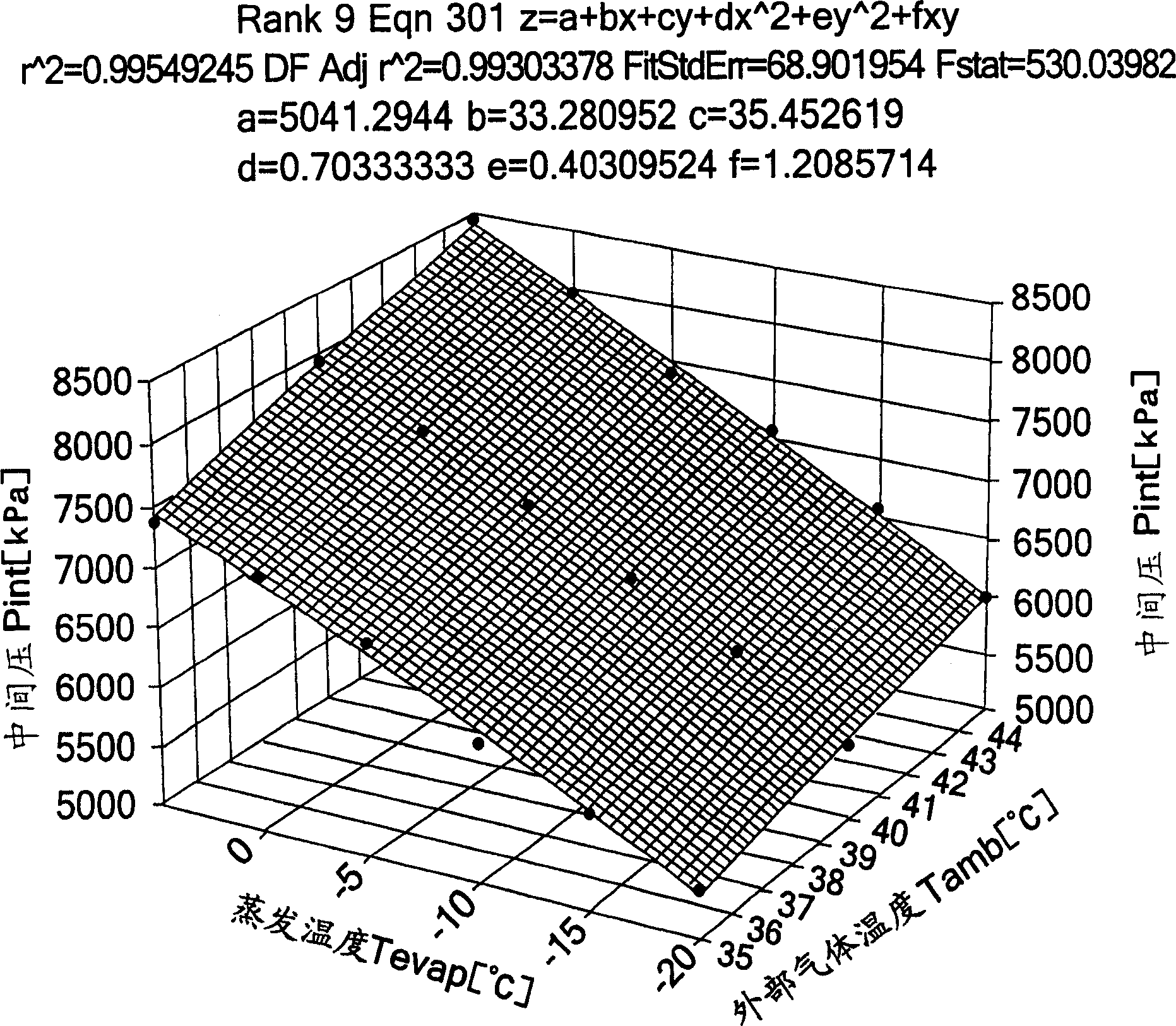

[0172] In addition, in the separate cycle of the above-mentioned embodiment, the main expansion valve 106 (main throttling device) and the auxiliary expansion valve 109 (auxiliary throttling device) are formed separately to control throttling separately, but it goes without saying that the main expansion valve 106 (main throttling device) can also be divided into two parts. Flow device and auxiliary throttling device are integrated. At this time, the high-pressure refrigerant output from the radiator 105 is not divided into a main refrigerant flow and an auxiliary refrigerant flow before the intermediate heat exchanger 107 as in the above embodiment, and all the refrigerant flows through the intermediate heat exchanger 107 For cooling, it is necessary to diverge them after passing through the intermediate heat exchanger 107 . Figure 11 It is a schematic diagram of an expansion device of an embodiment in which the above-mentioned two expansion devices are integrated.

[0173]...

Embodiment 3

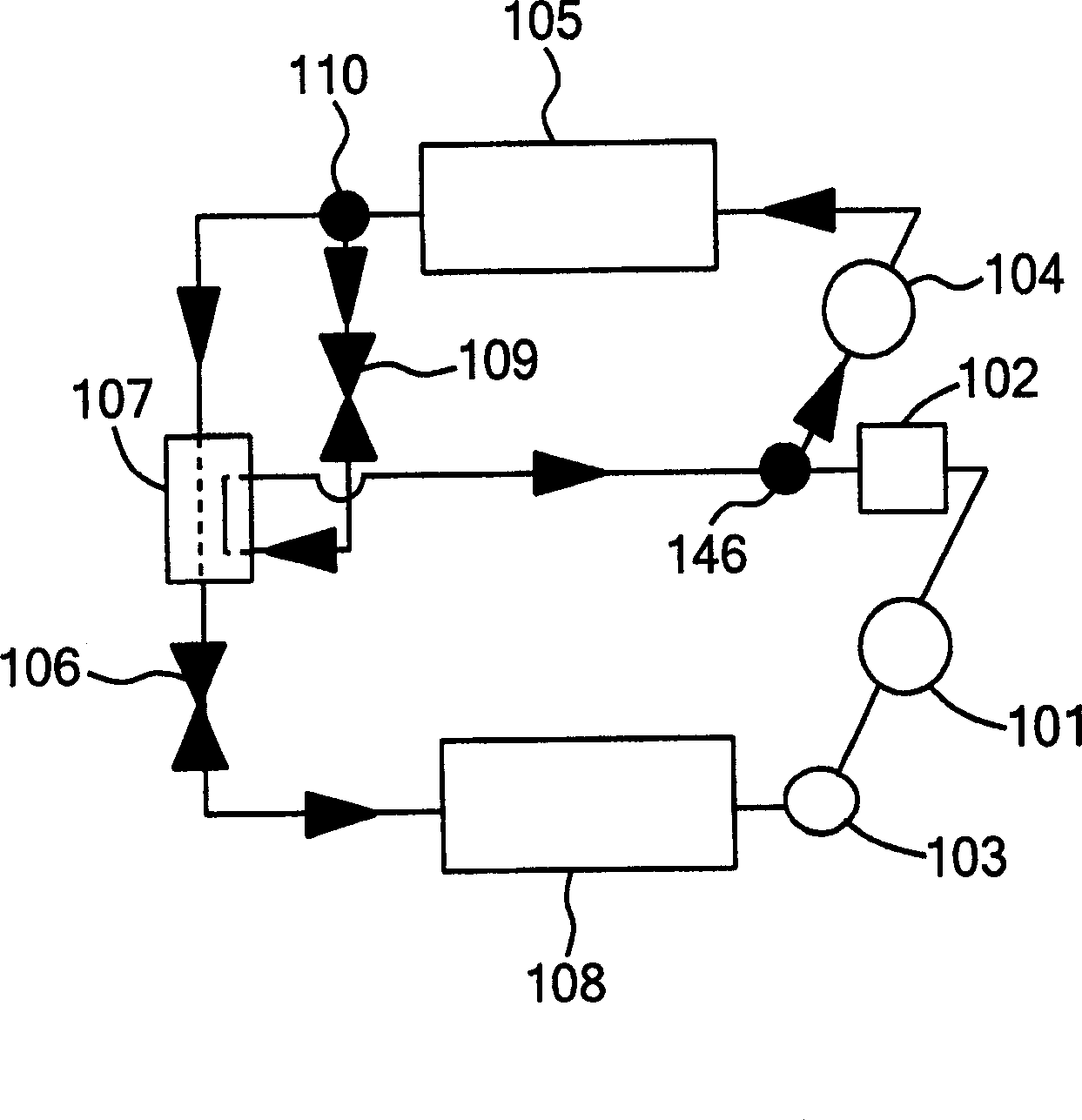

[0177] Moreover, the refrigerating device of the present invention is not limited to the device of the above-mentioned embodiment, and can also be applied to a refrigerating device in which a circuit is formed by other multiple evaporators and heat radiators. Figure 12 is a block diagram of the refrigeration device of this embodiment. Figure 12 The refrigeration unit 300 is shown as a split-cycle unit capable of mixed operation for cooling, heating and / or hot water supply. The split cycle of this embodiment consists of the low-pressure side compressor 301 and the high-pressure side compressor 302 of this occasion as the compression device; the first heat exchanger 305, the second heat exchanger 306 and the third heat exchanger as the utilization side heat exchanger. The exchanger 307; the fourth heat exchanger 308 which is a heat source side heat exchanger, etc. are comprised.

[0178] The first heat exchanger 305 and the second heat exchanger 306 are heat exchangers used f...

Embodiment 4

[0195] Figure 13 is a block diagram of a split cycle device according to another embodiment of the present invention. Two evaporators 405 and 406 capable of cooling in different temperature ranges are provided in the split circulation device 400 of this embodiment. That is, the split cycle device 400 of this embodiment consists of a low-pressure side compression device 401 constituting a compression device, an intercooler 412, a confluence device 413 as a converging device for converging two refrigerant flows, and a high-pressure side compression device that also constitutes a compression device. 402, heat radiator 403, flow splitter 404 as flow splitting device, intermediate heat exchanger 410, internal heat exchanger 415, auxiliary expansion valve 409 as auxiliary throttling device, main expansion valve 407 as main throttling device, the same The main expansion valve 408, the evaporators 405 and 406 as the main throttling means are constituted. The throttling amount of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com