Automatic sequencing feeding machine

An automatic sorting and feeding machine technology, applied in the direction of automatic/semi-automatic lathes, turning equipment, feeding devices, etc., can solve problems such as hindering the continuity of the process, disorderly storage, and difficulty in reaching the level of automation in the factory, and achieve simple structure and applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

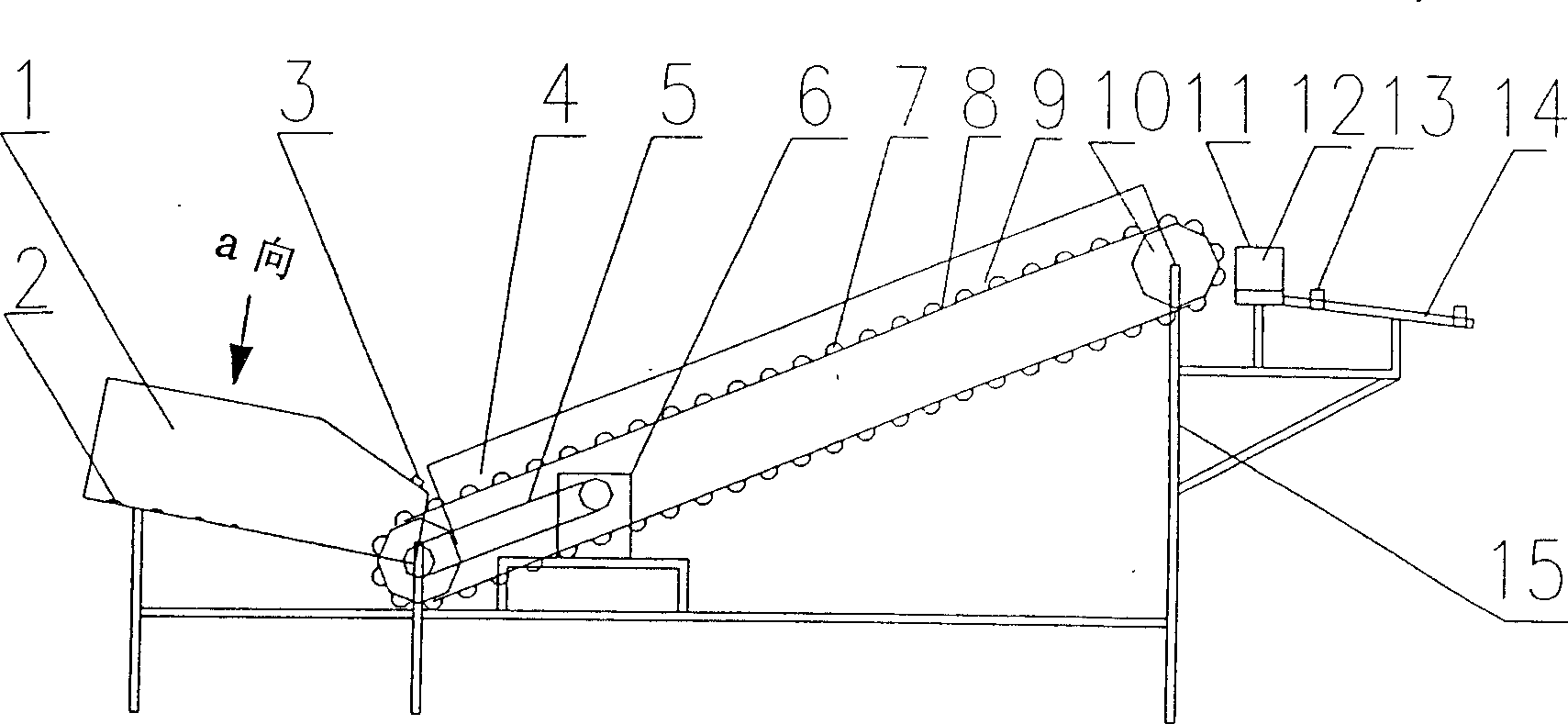

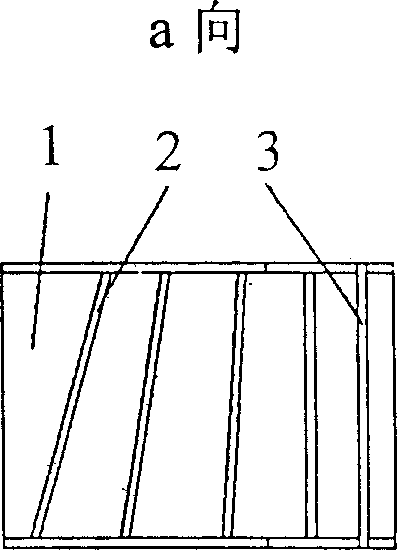

[0014] Such as figure 1 , figure 2 As shown, the present invention fixes the inner side of the lower end of the hopper mouth of the feeding hopper 1 to one end of the bottom of the lifting mechanism 4, the top of the lifting mechanism 4 is connected to the feedway part 11, and the whole machine is fixed on the support 15.

[0015] 1) The inner channel of the hopper 1 is provided with a straightening strip 2, and the inclination angle of the straightening strip 2 decreases successively from top to bottom; a stop bar 3 is provided above the outlet of the hopper 1 as a rejector to ensure that the sequence of the lifting process is consistent.

[0016] 2) The lifting mechanism 4 is provided with a chain 5, a motor 6, an arc-shaped step 7, a conveyor belt 8, a baffle plate 9 and a runner 10; wherein the arc-shaped step 7 is equidistantly located on the surface of the conveyor belt 8; the motor 6 is located at The middle of the runners 10 on both sides is fixed on the bracket 15; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com