Permanent magnetic suspending shaft

A technology of magnetic suspension shaft and magnetic suspension bearing, applied in the direction of bearing, shaft and bearing, mechanical equipment, etc., can solve the problems of poor reliability, high cost and large volume, and achieve the effect of stable working state, light weight and large suspension force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following content is a detailed description of the present invention in conjunction with the accompanying drawings, but should not be construed as a limitation of the present invention.

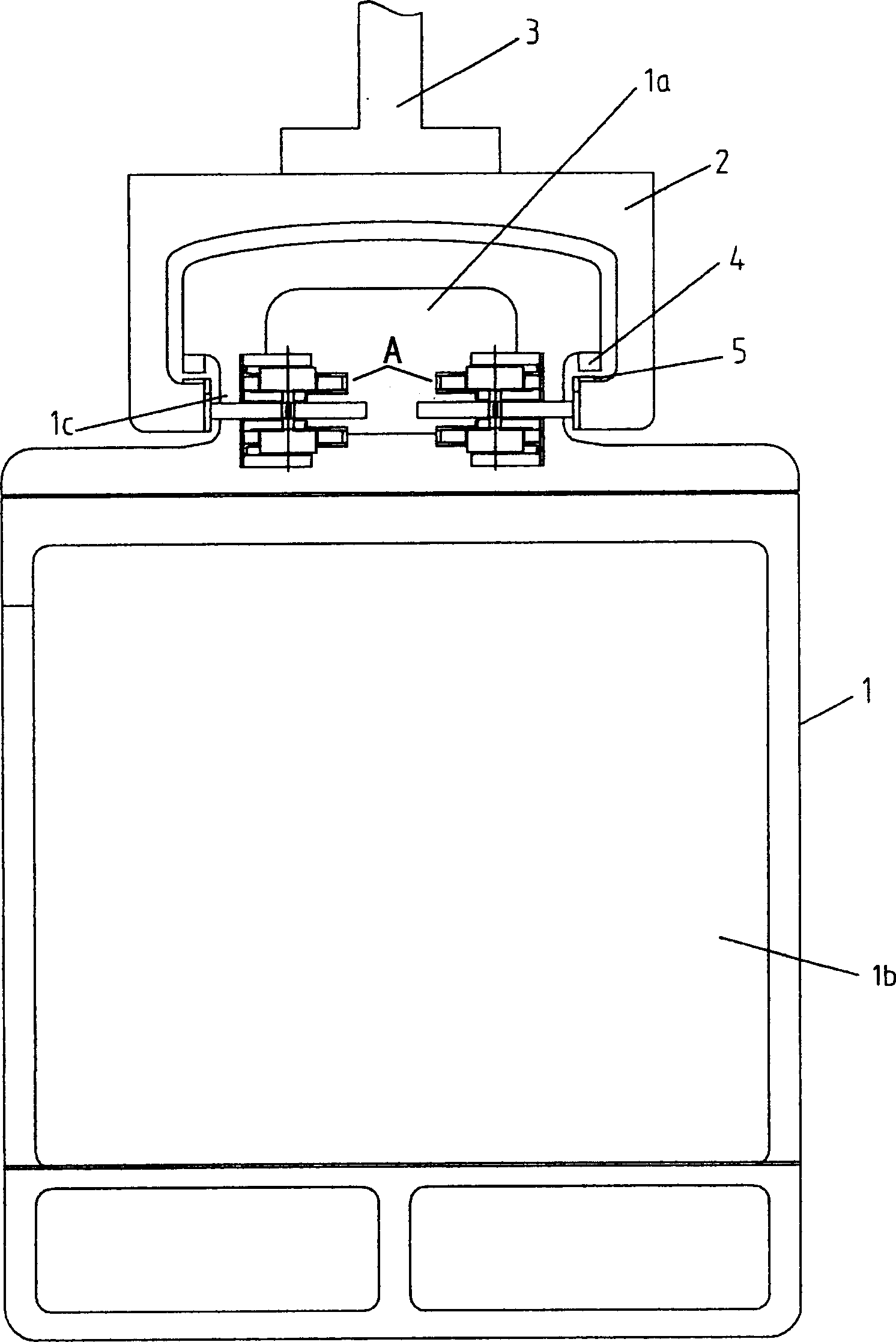

[0024] In order to facilitate the understanding of the working process of the permanent magnetic levitation shaft, please refer to figure 1 . The maglev train 1 is embedded in the bow-shaped suspension pillow 2, and the bow-shaped suspension pillow 2 is fixed below the I-beam 3. The train wing magnet 4 is corresponding to the same pole of the track magnet 5, and its magnetic field repulsive force will suspend the train. The train has an up-and-down structure, the upper part is the suspension power cabin 1a, and the lower part is the compartment 1b, and the guide wheel magnetic suspension shaft is fixed on the inner side of the suspension power cabin wall 1c, that is, the permanent magnetic suspension shaft A of the present invention.

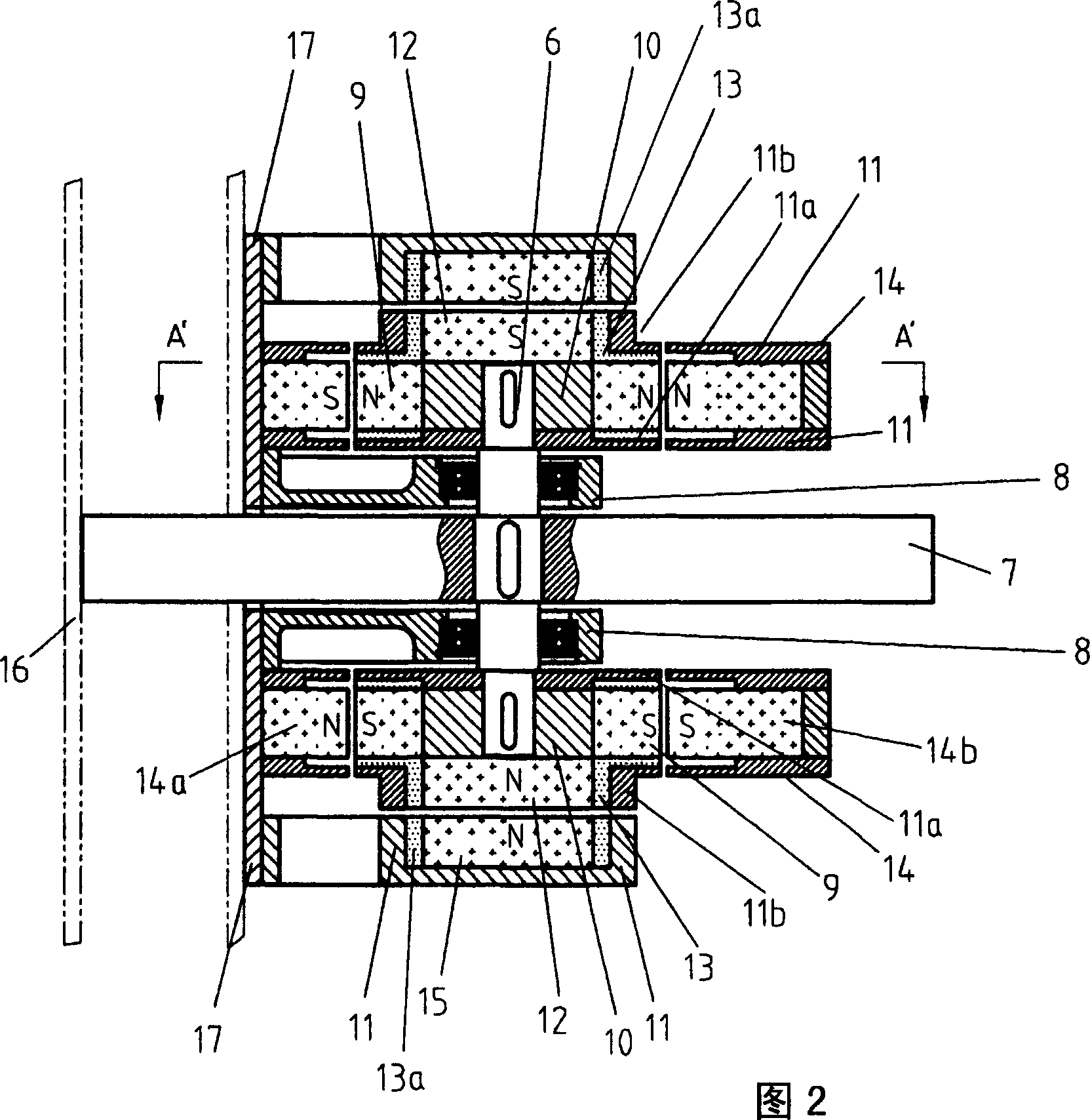

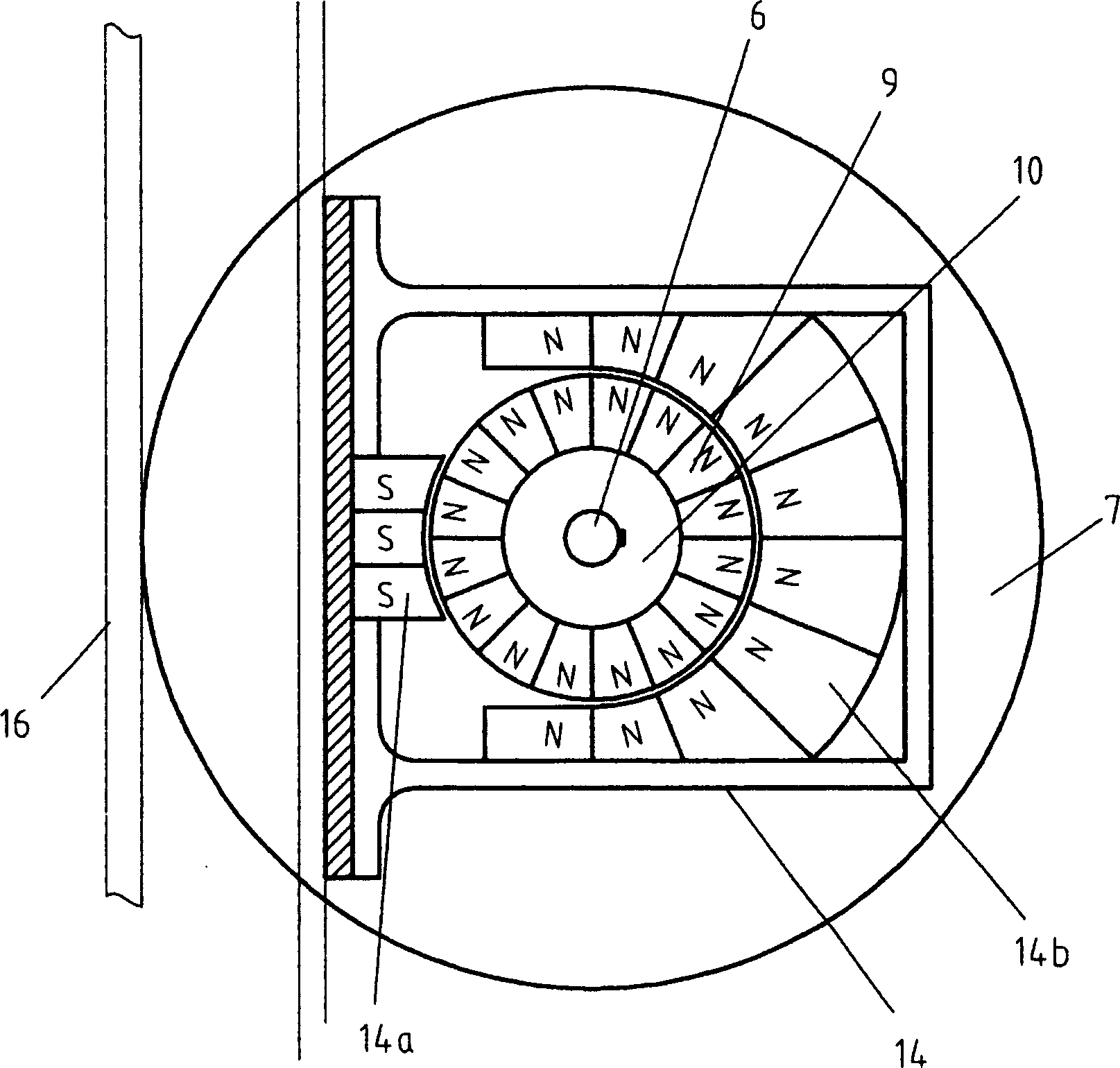

[0025] Then referring to Fig. 2,3, the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com