Induction melting cold crucible with full suspension and strong stirring ability

A technology of induction melting and cold crucible, applied in the direction of crucible furnace, stirring device, furnace, etc., can solve the problems of affecting alloy uniformity, waste, weak electromagnetic stirring ability, etc., and achieve the goal of reducing product quality, reducing energy consumption, and preventing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that the present disclosure can be more thoroughly understood and the scope of the present disclosure can be fully conveyed to those skilled in the art.

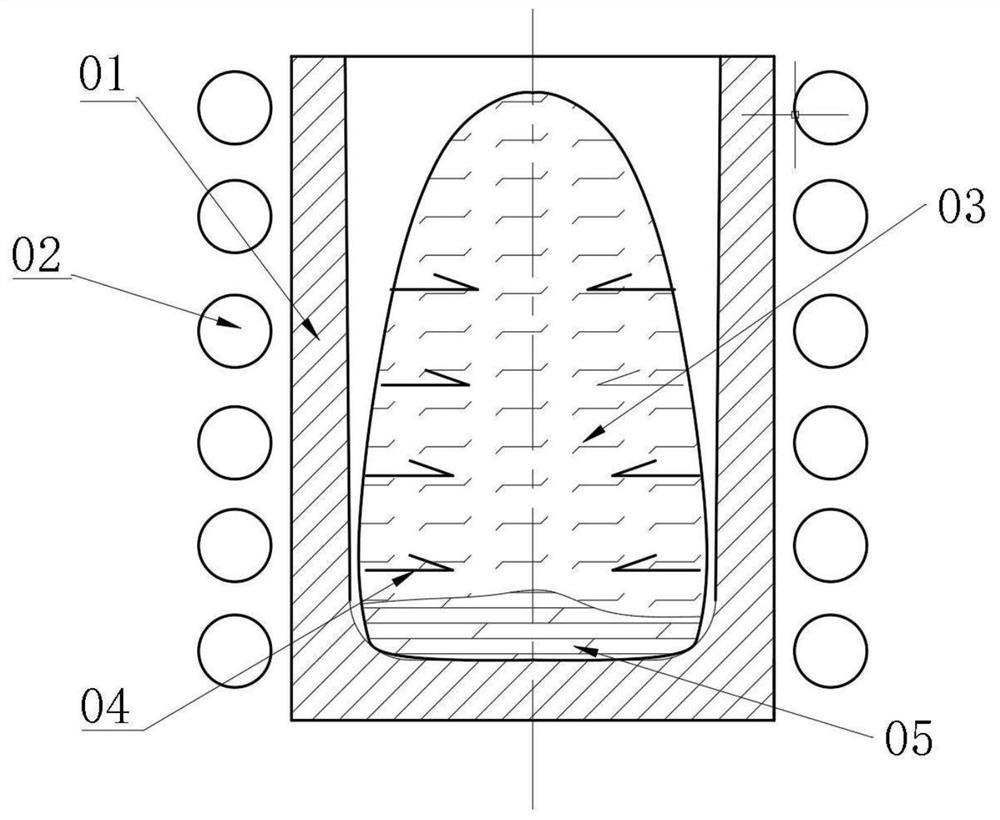

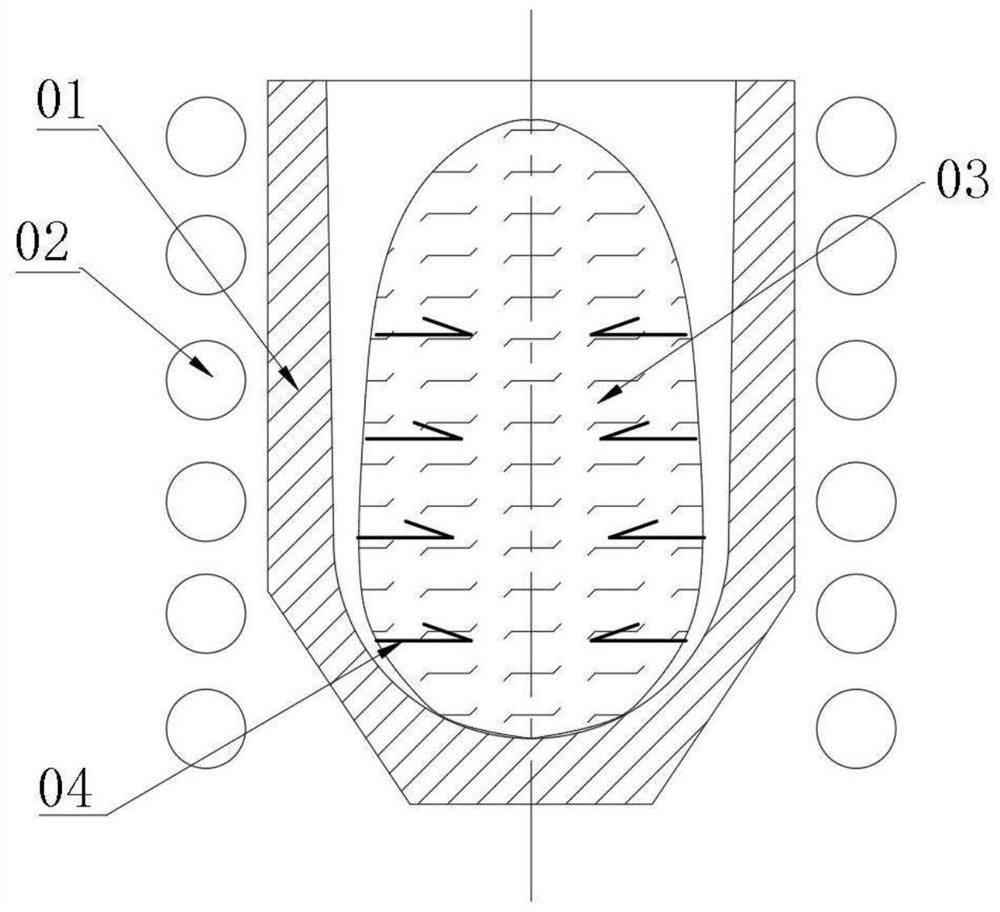

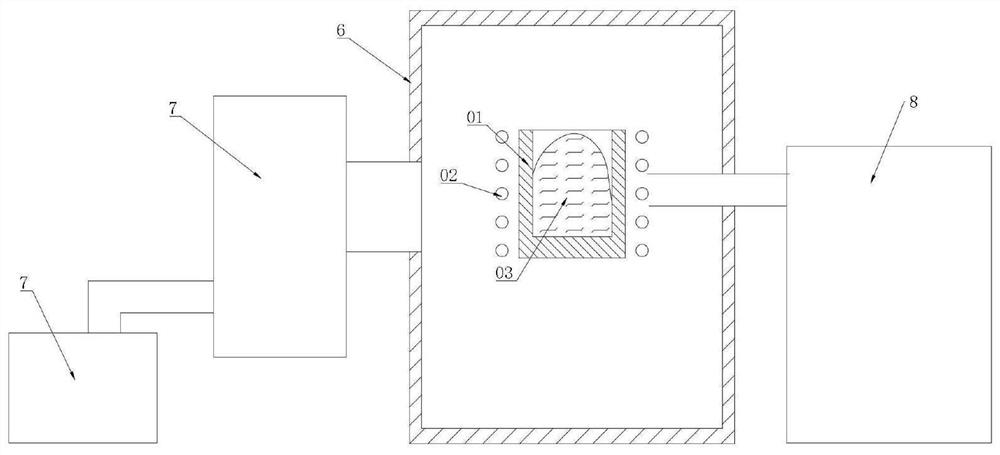

[0047] like image 3 As shown, the cold crucible vacuum induction melting equipment includes vacuum furnace body 6, vacuum unit 7, induction power supply 8 and other components. The split cold crucible is placed in the vacuum furnace body 6, and the oscillating current output by the high-frequency induction power supply 8 is sent to the induction coil surrounding the crucible 1, and the generated electromagnetic field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com