Dost-treatment production process and apparatus for glass fiber fabric for high speed abrasive wheel

A technology of glass fiber and production method, which is applied in the field of post-processing production and equipment of glass fiber mesh for high-speed grinding wheels, can solve the problem of insufficient bonding strength between surface treatment agent and abrasive binder, easy oval appearance of grinding wheel mesh, and strong warp and weft strength. Non-uniformity and other problems, to achieve the effect of great practical and popularization value, increased baking temperature gradient, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

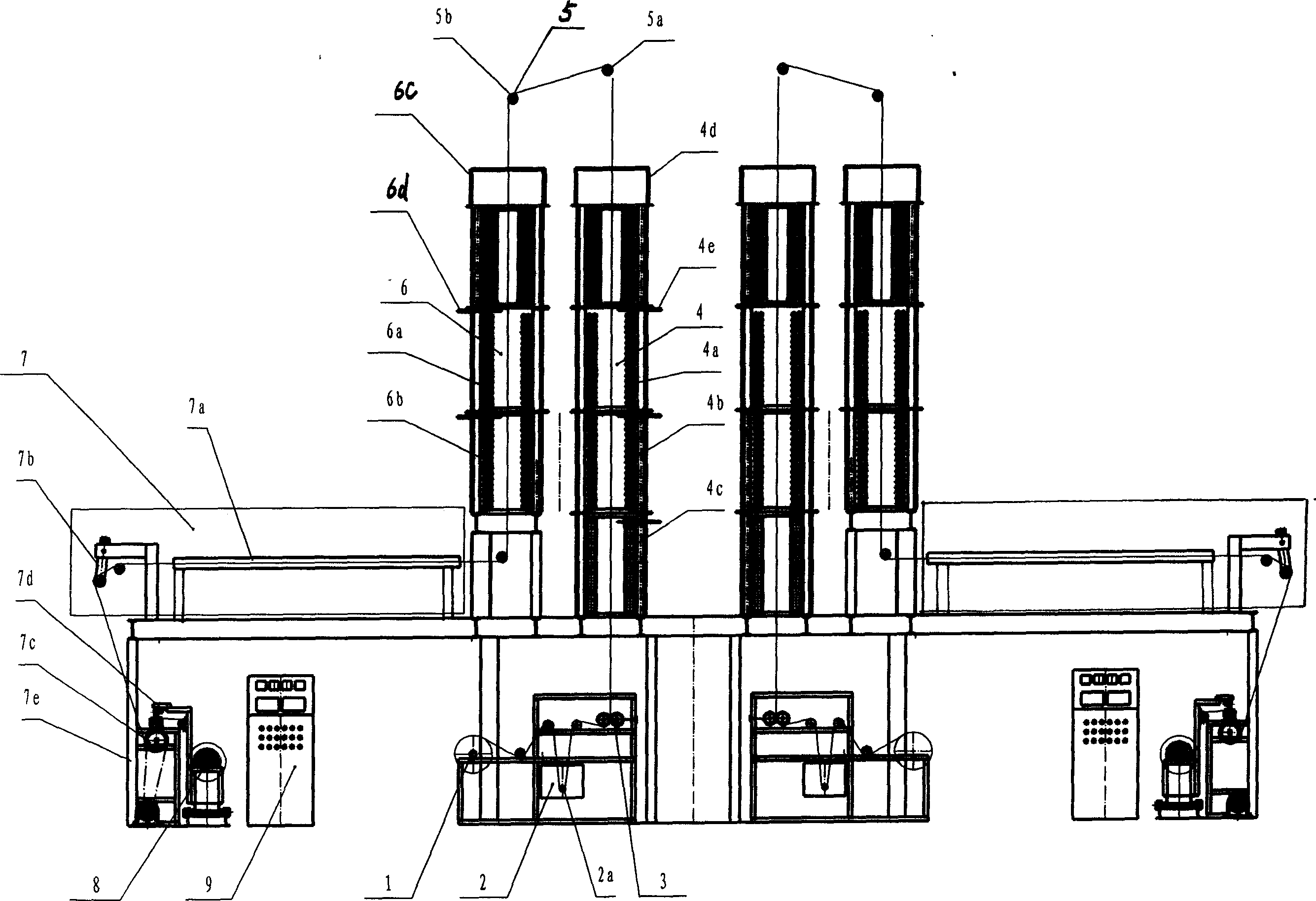

[0014] Post-processing production method of glass fiber mesh cloth for high-speed grinding wheel: Firstly, the woven medium-alkali or alkali-free glass fiber mesh cloth is wound on the dispensing roller and placed on the dipping mechanism; it is to be processed under the drive of power The mesh bypasses the rubber roller and enters the dipping tank to impregnate the resin glue; driven by the power, the impregnated mesh enters the squeeze roller device, and then enters the drying tunnel I for drying; Stage II carries out secondary drying; the mesh cloth after secondary drying enters the expanding mechanism and enters the expanding process, and then is wound up on the cloth take-up roller. The first drying and the second drying adopt a vertical non-contact method for drying treatment. The first drying and the second drying use steam or heat transfer oil, electric heating tubes, and far-infrared heaters to heat and dry the mesh cloth alternately. The expansion process is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com