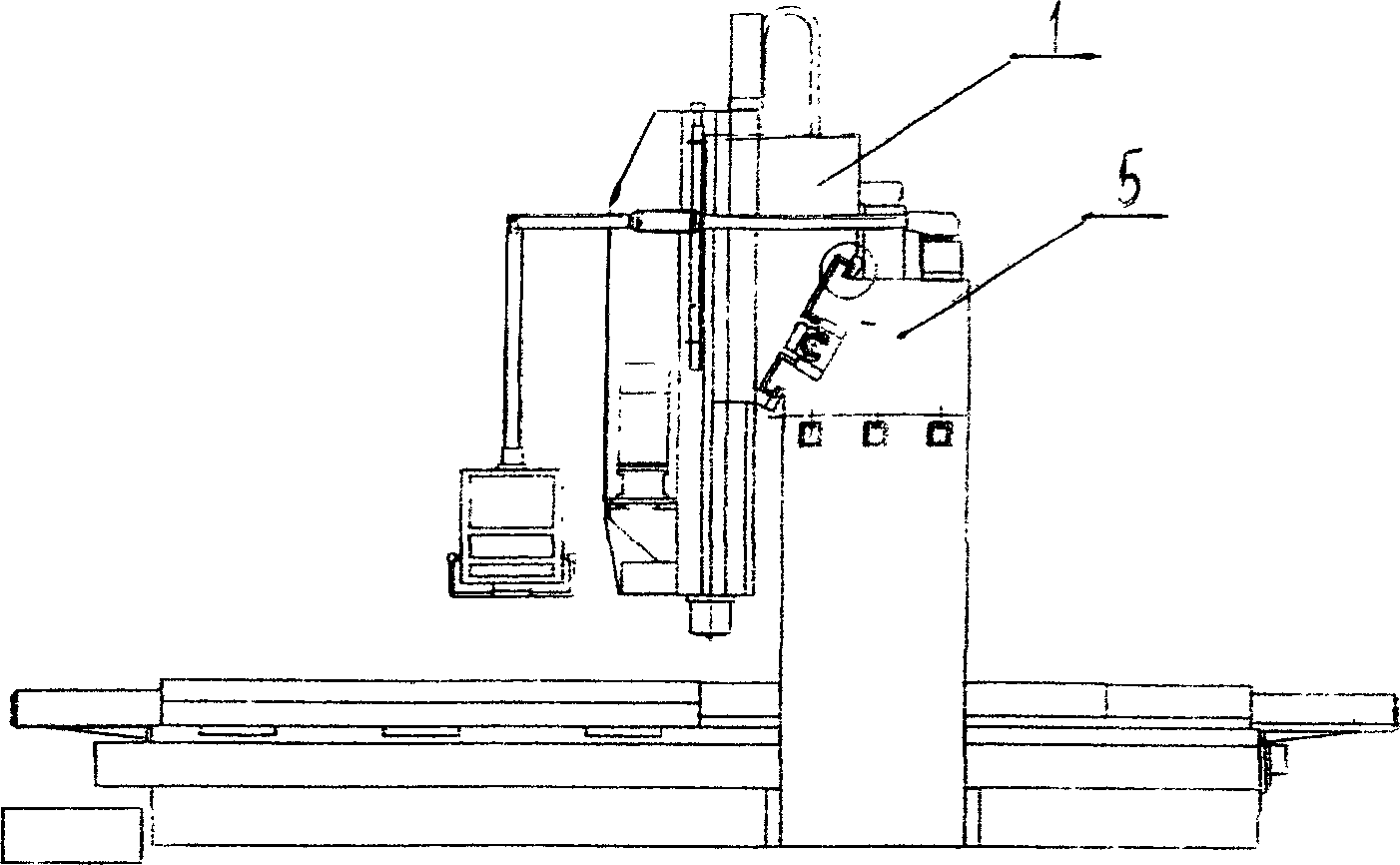

Guide rail structure for Y-axis carriage and cross beam of numerically controlled planer boring/milling machine

A beam and Y-axis technology, applied in the field of CNC machine tools, can solve the problems of multiple manual grinding of the joint surface between the pressure plate and the lower guide rail surface, and achieve the effects of guaranteed running accuracy, guaranteed machining accuracy, and reliable running accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

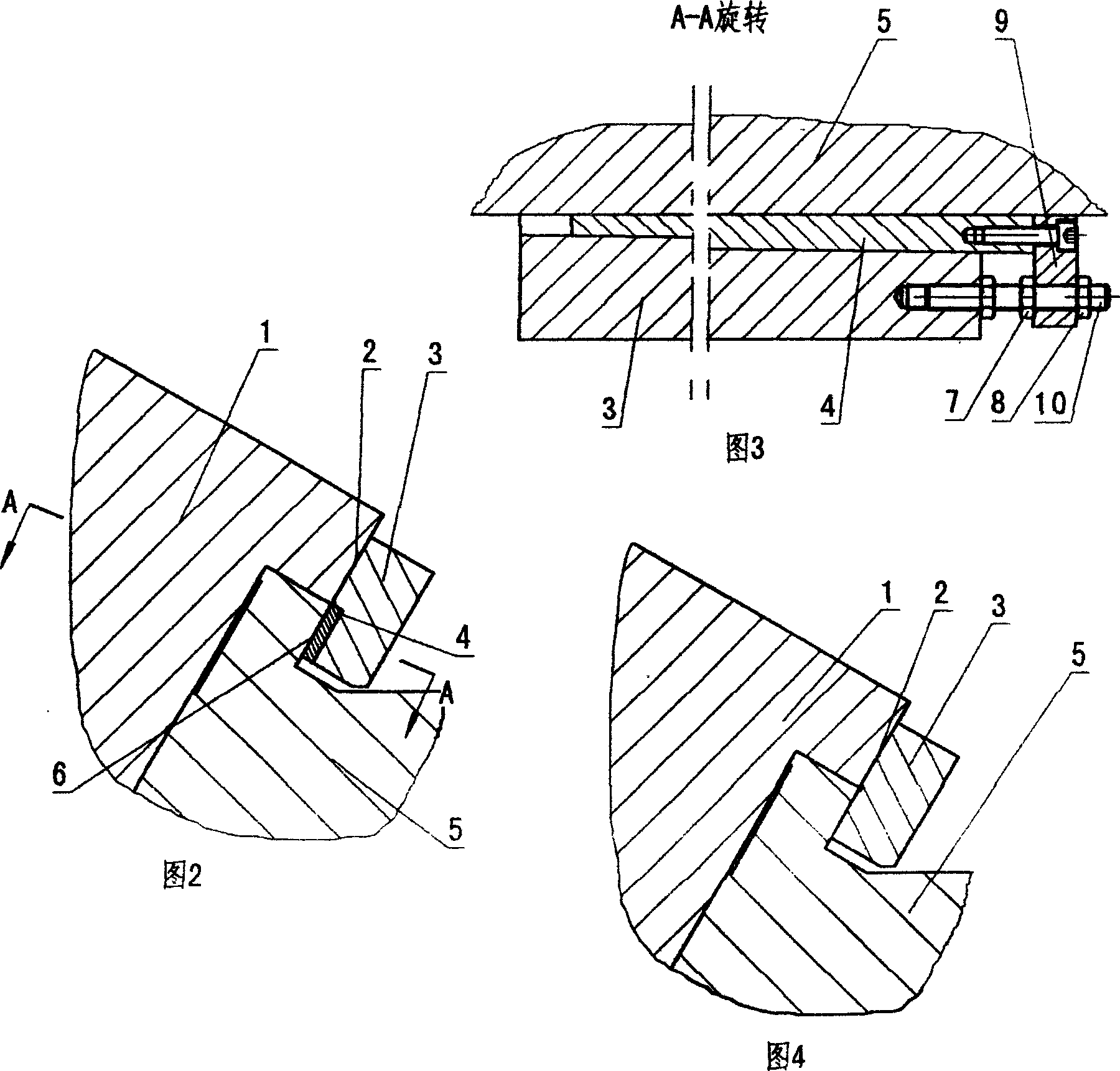

[0017] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0018] The present invention is an improvement to the prior art - VMC2000 CNC gantry boring and milling machine and machining center, which is symmetrically located on both sides of the 30° inclined guide rail where the Y-axis carriage 1 and the beam 5 cooperate. The present invention includes a Y-axis carriage 1 , a beam 5 , a pressing plate 3 and a wedge 4 . The pressure plate 3 is arranged on the lower side of the lower guide rail surface 2 of the Y-axis carriage and the lower guide rail surface 6 of the crossbeam, and a notch groove with an "L" shape in section is provided on the pressure plate 3 . The pressure plate 3 is closely attached to the lower guide rail surface 2 of the Y-axis carriage. The notch of the pressure plate 3 is set on the lower side of the lower guide rail surface 6 of the beam. In the notch groove of the pressure plate 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com