Polylactic acid resin composition, process for producing the same and molding thereof

A technology of polylactic acid resin and composition, applied in the field of polylactic acid resin composition, can solve the problems such as inability to obtain the proportion and insufficient improvement of heat resistance, and achieve the effect of high crystallization proportion and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

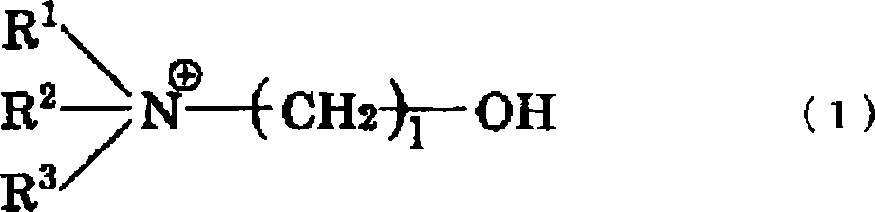

[0086] Organicization of Layered Clay Minerals

[0087] 100 g of sodium montmorillonite (Kunipia F, manufactured by Kunimine Industries Co. Ltd., cation exchange capacity: 115 meq / 100 g) was dispersed in 5000 ml of water at 80° C.; 59.2 g of dihydroxyethylmethyl stearyl bromide Ammonium was dissolved in 2000ml of water at 80°C; subsequently, the two were mixed to carry out the organicization of montmorillonite; the organicized montmorillonite (hereinafter referred to as 18(OH) 2 -Mont) washed three times, freeze-dried, and crushed. 18(OH) determined by ignition method 2 -Mont has an inorganic residue of 63%.

[0088] Preparation of Polylactic Acid-Layered Clay Mineral Complex

[0089] 100g of L-lactide, 3.5g of 18(OH) 2 -Mont and 200 mg of tin octoate were added to the reactor and vacuumed to 10 -2 mmHg; then, the temperature was gradually raised while the mixture was fully stirred, and kept at 160°C for 1 hour; the reaction product was dissolved in chloroform and dropped i...

Embodiment 2-4

[0095] The DSC measurement of the film of the polylactic acid resin composition was carried out as described in Example 1, but the retention temperature {(A)°C} after melting was 120°C (Example 2), 100°C (Example 3) and 80°C ( Example 4). The obtained results are shown in Table 1.

Embodiment 5

[0097] Prepare the film of polylactic acid resin composition as described in Example 1, and measure on DSC, but difference is, by adding 0.5g of 18(OH) in the preparation step of polylactic acid-layered clay mineral combination 2 -Mont to obtain a poly-L-lactic acid-layered clay mineral combination (PLLA-clay #2) having a weight average molecular weight of about 120,000 and a layered clay mineral content of 0.3% by weight (based on the inorganic component), Use PLLA-clay #2 instead of PLLA-clay #1. The obtained results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com