A kind of mold powder for peritectic steel slab continuous casting and its formula

A mold powder and slab continuous casting technology, applied in the field of continuous casting and steel casting, can solve the problems of longitudinal cracks on the surface of the casting slab, transverse temperature gradients, and fluctuations in the liquid level of the mold, so as to solve the fluctuation of the liquid level. problems, the effect of increasing the crystallization phase ratio, reducing the viscosity and melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

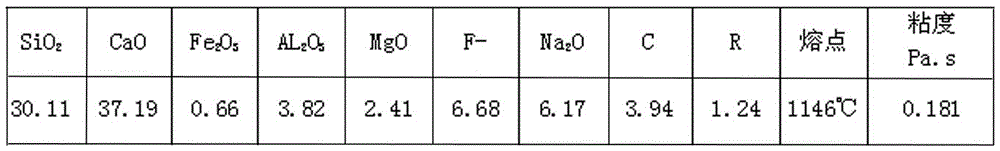

[0015] Example 1: It turned out that the liquid level fluctuation phenomenon in the production process of a certain peritectic steel was serious, and the occurrence rate of the liquid level fluctuation exceeding ±10 mm accounted for 29.78% of the production furnaces, resulting in cracked waste products accounting for 41.29% of the total waste products. After using this mold flux , the three-layer structure of raw slag layer, sintered layer and molten layer can be formed smoothly on the molten steel in the mold, and the molten layer of mold slag can normally flow into the mold and the slab to play a sufficient lubricating role, and the liquid level fluctuates All can be stabilized within ± 3mm, and the amount of cracked waste is greatly reduced, accounting for only 7.16% of the total waste. The actual controlled casting speed of this steel grade is increased from 1.05m / min to 1.2m / min-1.4m / min.

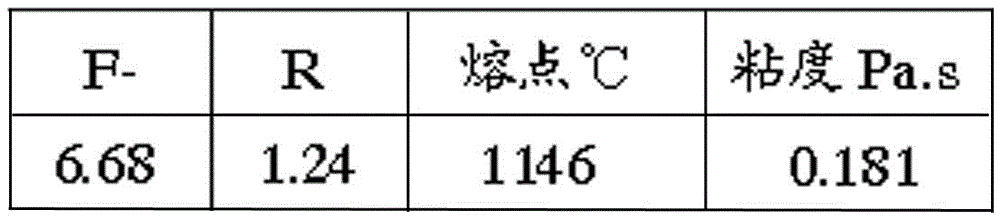

[0016] Mold flux F provided by the present invention - content increased, Na 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com