Superfine stainless steel fibre producing technology

A production process, stainless steel technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as frequent broken wires, achieve faster damage speed, reduce broken wires at export, and increase axial cutting capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A production process of ultra-fine stainless steel fibers:

[0024] Raw materials——rough drawing machine——rough drawing semi-finished product——inspection

[0025] Rough drawing semi-finished product - micro drawing machine - fiber semi-finished product - inspection

[0026] Fiber semi-finished products—annealing furnace—fiber finished products—inspection

[0027] It consists of three steps:

[0028] (1) The stainless steel raw materials are rough-drawn semi-finished products through the rough-drawing machine,

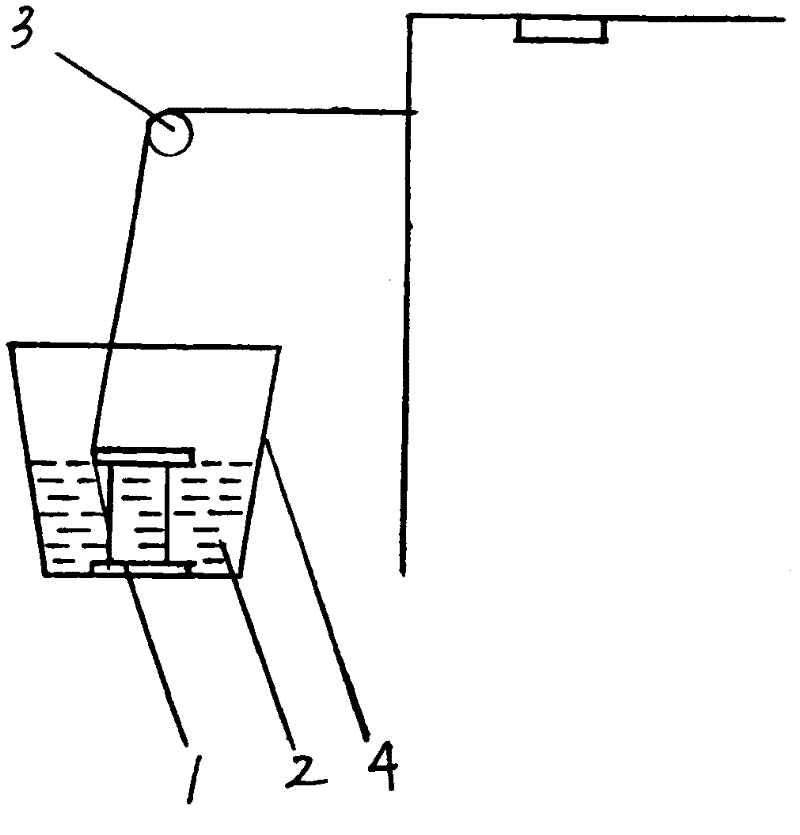

[0029] (2), stainless steel rough drawing semi-finished product passes micro-drawing machine into fiber semi-finished product, and stainless steel rough drawing semi-finished product 1 is placed in the container 4 that fills lubricant 2, rough drawing semi-finished product 1 enters micro-drawing machine after passing through guide wheel 3;

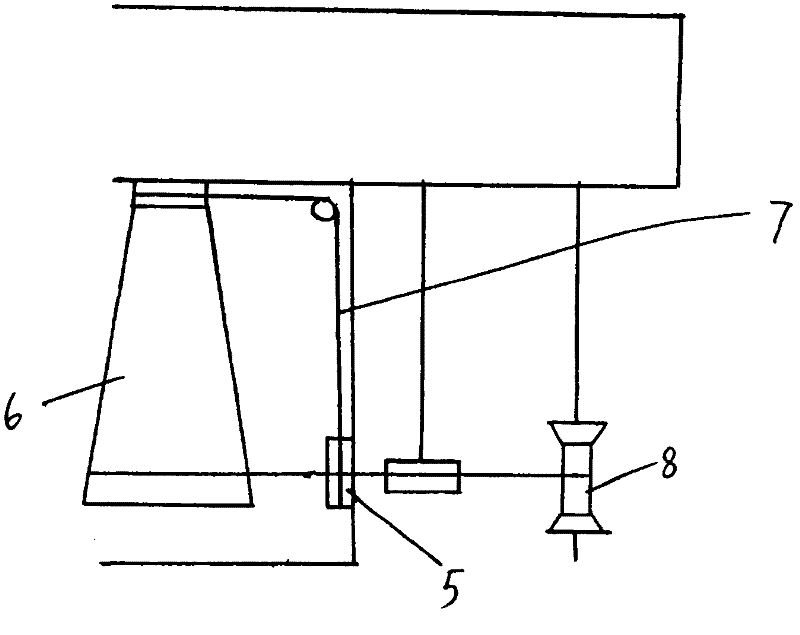

[0030] A guide ring 5 is installed at the exit of the micro-drawing machine. The fiber semi-finished product passes thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com