Device for recovering waste water and waste heat

A waste heat recovery and waste water technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of losing the effect of cold and heat exchange, depositing dirt in waste water and hot water channels, reducing heat exchange efficiency, etc., to reduce production costs , easy to remove dirt, wide practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

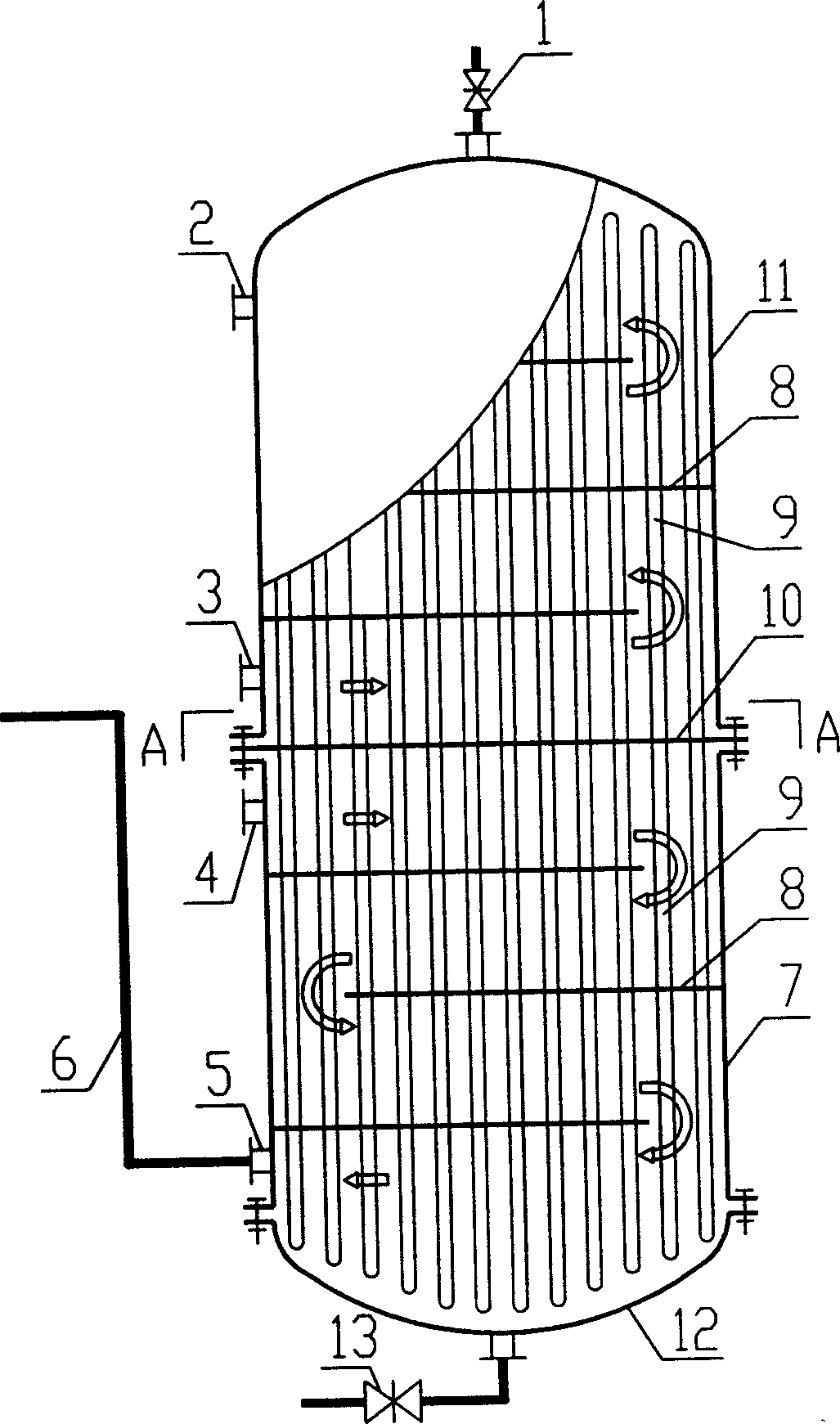

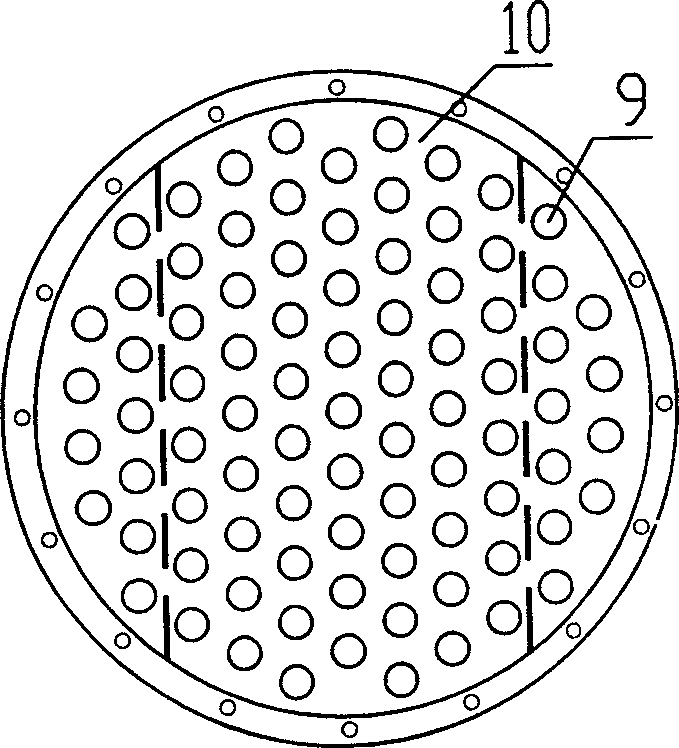

[0012] The present invention is a wastewater waste heat recovery device, figure 1 As shown, it is fastened up and down by the cold water heat exchange cylinder 11 and the hot water heat exchange cylinder 7, and is fixed as a vertical water storage tank by bolts. The junction of the cold water heat exchange cylinder 11 and the hot water heat exchange cylinder 7 is provided with a partition 10 that separates and seals them, and a circular baffle plate 8 is installed inside the cold water heat exchange cylinder 11 and the hot water heat exchange cylinder 7. A plurality of through holes are evenly opened on the shaped baffle plate 8 and the partition plate 10, and a plurality of gravity heat pipes 9 matched therewith are arranged in the through holes, and the plurality of gravity heat pipes 9 are evenly distributed and fixed on the sealing partition plate 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com