Multi-acid self-humidification composite proton exchange membrane for fuel cell and preparing process thereof

A proton exchange membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of increasing the volume and reducing the specific energy density of PEMFC, so as to improve the open circuit, maintain mechanical properties and stability, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

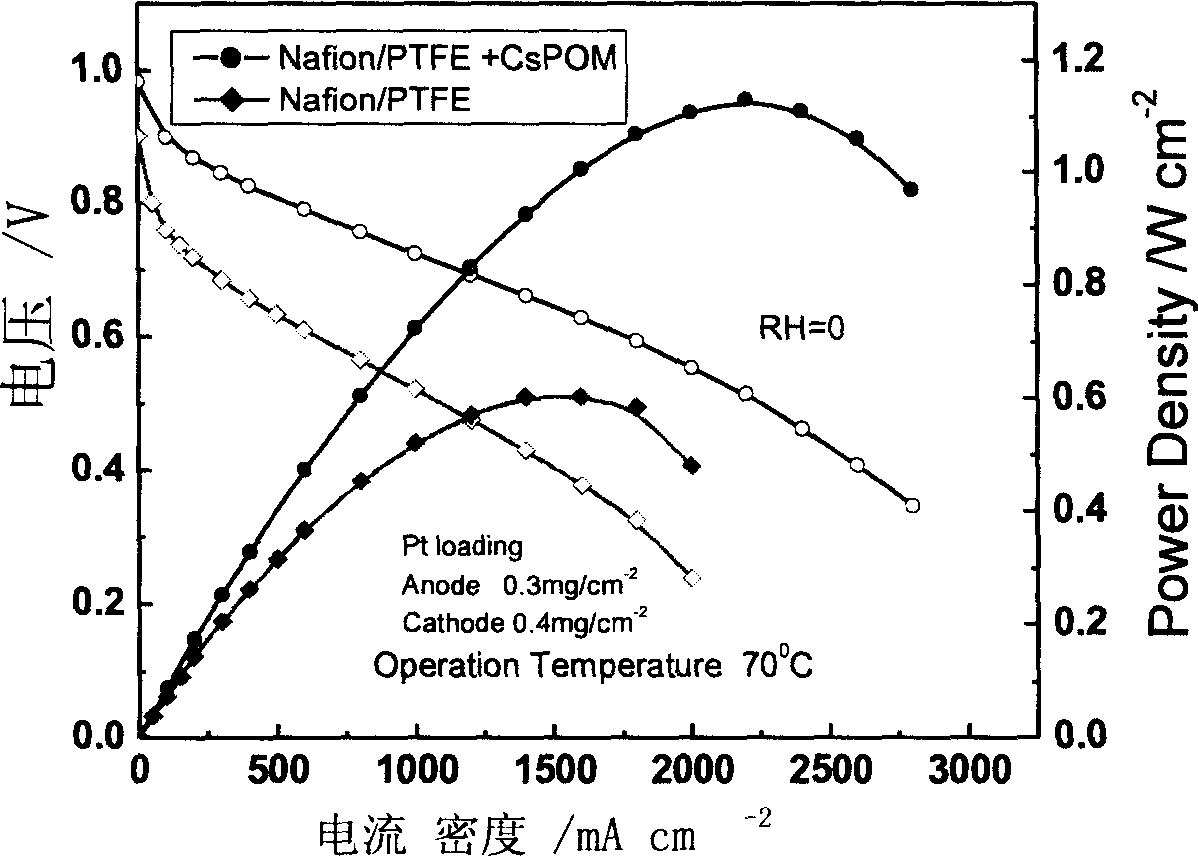

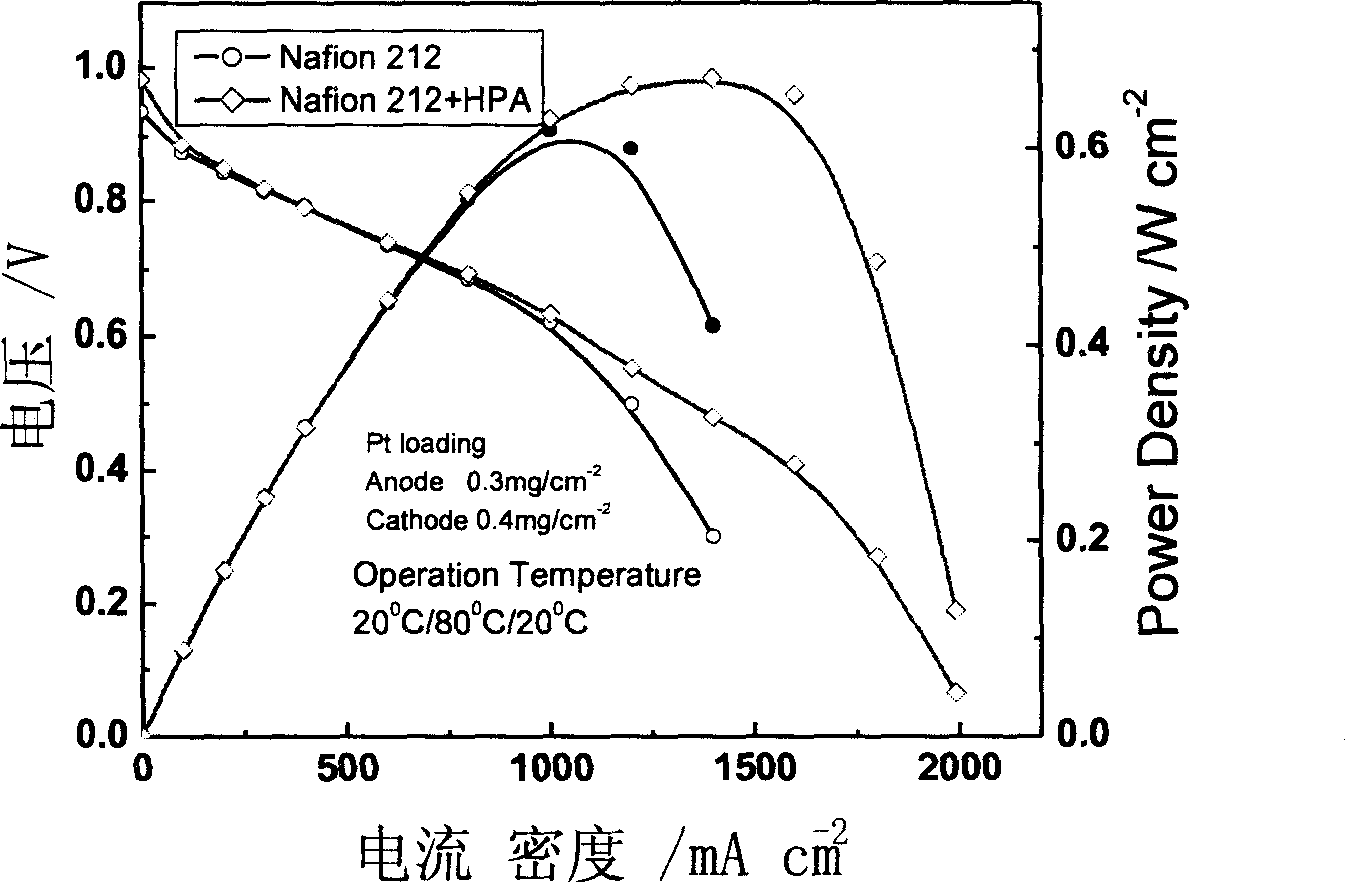

Image

Examples

Embodiment 1

[0027] Mix the aqueous solution of phosphotungstic acid with a weight concentration of 20% and the isopropanol solution of Nafion with a weight concentration of 10% at a weight ratio of Nafion:phosphotungstic acid=3:1, and then ultrasonically (frequency: 4000 Hz) for 2 hours to mix uniform. Spray the mixed solution onto both sides of the Nafion212 membrane to form a proton exchange membrane with a self-humidifying layer; the thickness of the membrane is 0.054mm.

Embodiment 2

[0029] Mix silicotungstic acid ethanol solution with a weight concentration of 50% and SPEEK DMF solution with a weight concentration of 10% at a weight ratio of SPEEK: phosphotungstic acid = 3:1, and then ultrasonically (frequency: 4000 Hz) for 2 hours to mix evenly. Spray the mixed solution onto one side of the SPEEK membrane to form a proton exchange membrane with a self-humidifying layer; the thickness of the membrane is 0.052mm.

Embodiment 3

[0031] The aqueous solution of 40% phosphomolybdic acid and the NMP solution of sulfonated polysulfone with a weight concentration of 10% are mixed in a weight ratio of sulfonated polysulfone: phosphomolybdic acid=10:1, and then ultrasonic (frequency: 4000 Hz) Mix well for 2 hours. Spray the mixed solution onto both sides of the sulfonated polysulfone membrane to form a proton exchange membrane with a self-humidifying layer; the thickness of the membrane is 0.179mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com