Centrifuge for separation of liquids and solids with solids discharge using a piston or scraper

A centrifugal separator and mandrel technology, which is applied in the field of centrifuges and can solve problems such as unstable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

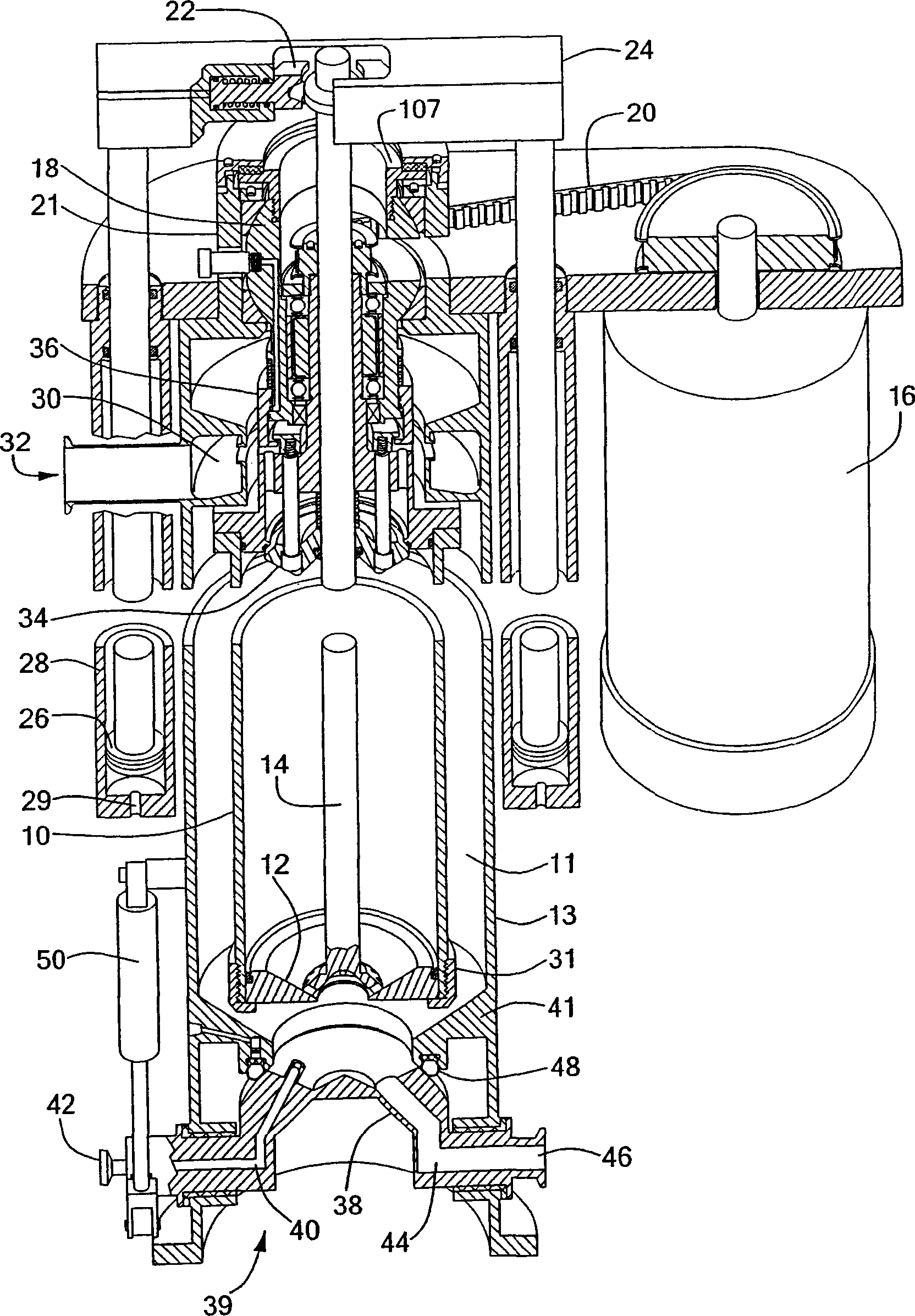

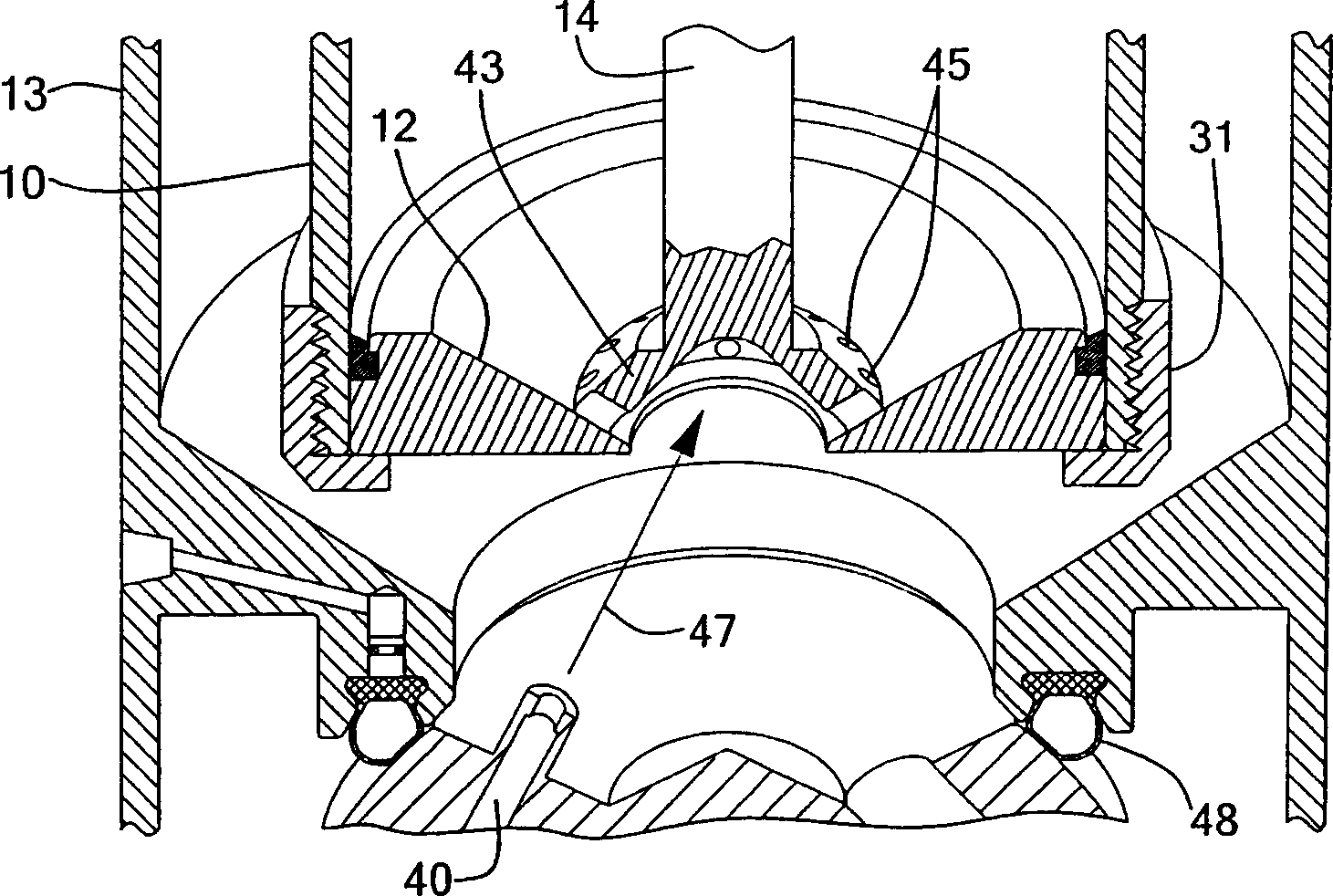

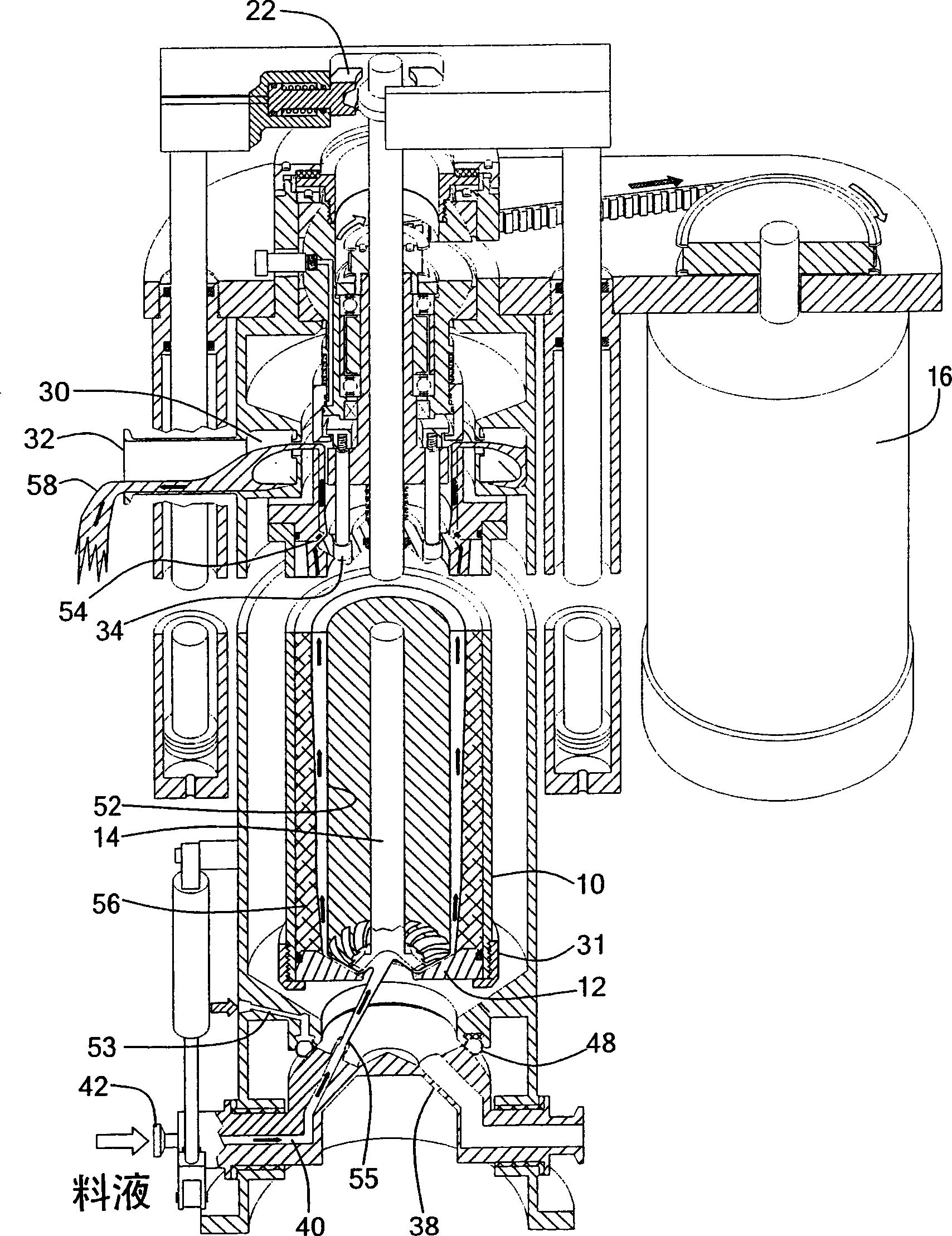

[0030] figure 1 Shows a vertical section of an automated tube bowl centrifuge separator with the middle section removed so that a horizontal section can also be shown. The centrifuge separator comprises a cylindrical separator bowl 10 mounted in the middle 11 of a separator housing 13 . The separator drum 10 is preferably a cylindrical drum having a relatively small diameter D and length L with a ratio L / D of about 5 / 1 or greater. Inside the separator drum 10 is mounted a piston mechanism consisting of a piston head 12 connected to a piston shaft 14 .

[0031] A variable speed drive motor 16 is connected to a drive pulley of a spherically mounted bearing and spindle mechanism 18 . This connection is formed by a drive belt 20 on an annular extension 21 of the shaft at the upper end of the separator housing 13 . The drive motor 16 is controllably operated to rotate the separator bowl 10 at the speed required to separate the feed liquid. A piston shaft clutch 22 is mounted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com