Electrode dressing on-line distinguishing method based on spot-welding of servo torch

A technology of servo welding gun and discrimination method, which is applied in the direction of electrode characteristics, welding equipment, resistance welding equipment, etc., can solve the problems that there is no online discrimination method for electrode grinding, and no online discrimination of servo welding gun electrode grinding has been found, so as to reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments are provided in conjunction with the technical scheme of the present invention:

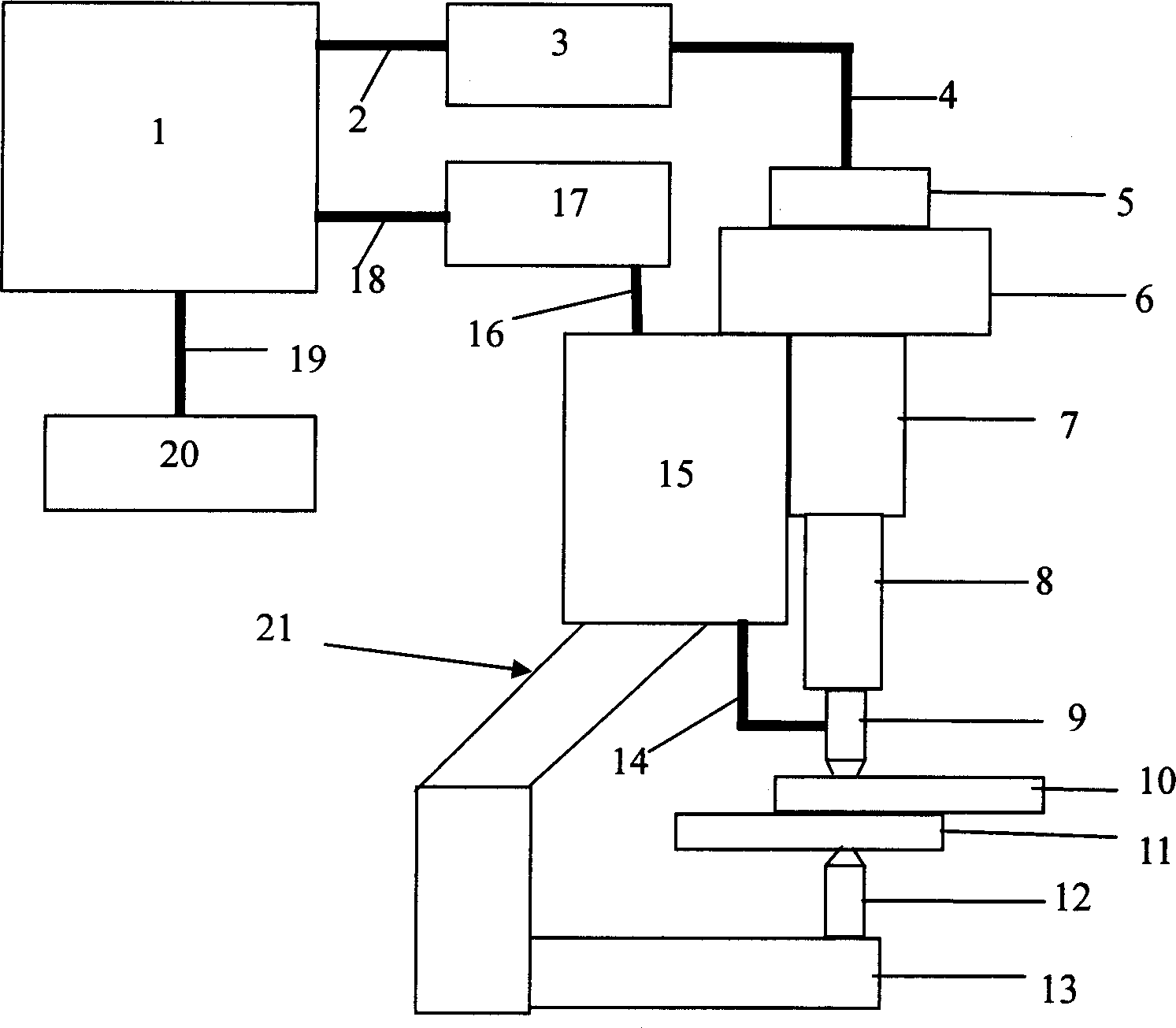

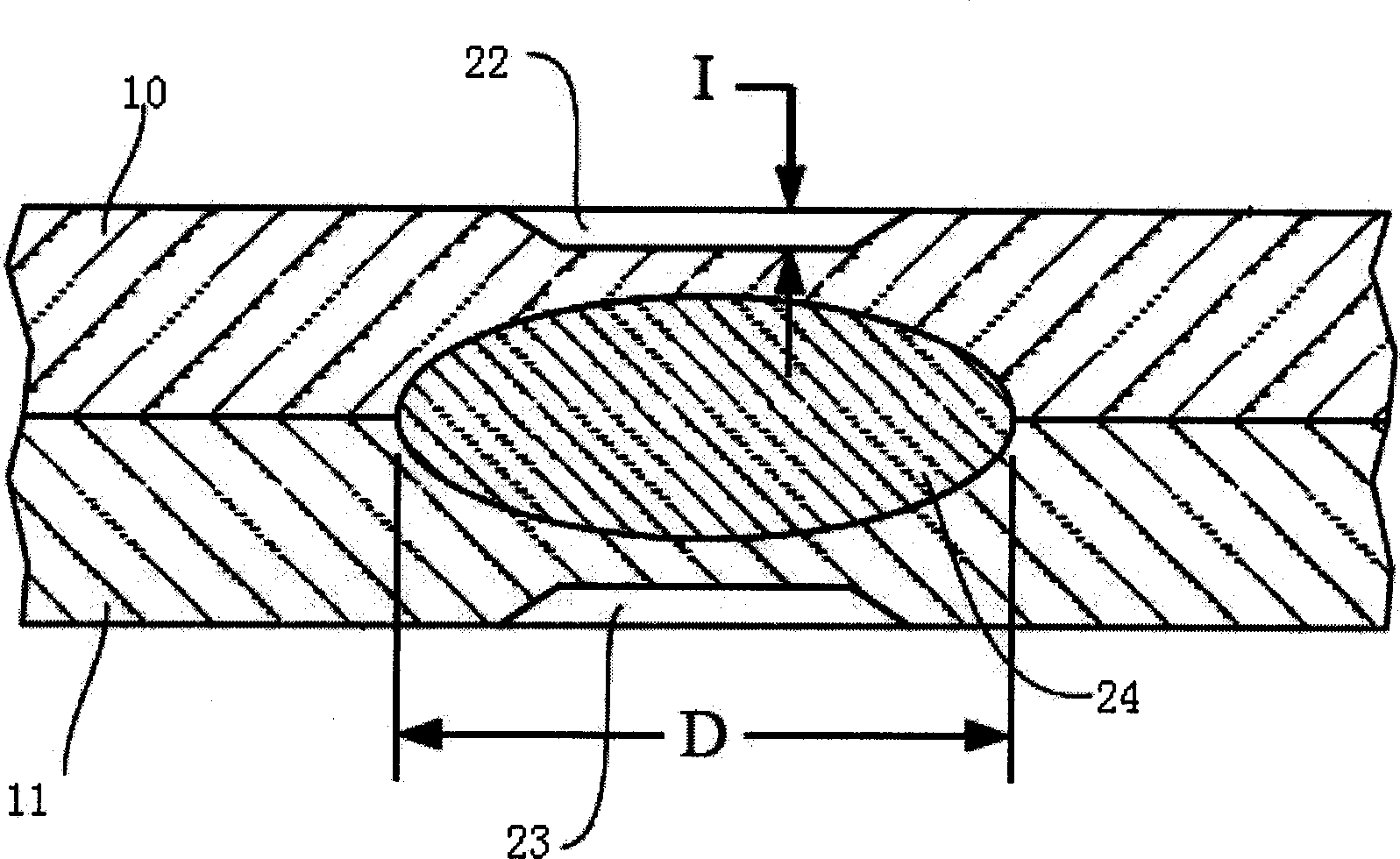

[0017] (1) This embodiment adopts the spot welding system of servo welding torch and robot integrated control to start welding, such as figure 1 As shown, the robot controller 1 transmits the motion control instruction to the robot 3 through the signal optical cable 2, and the robot 3 executes the motion instruction to move the servo welding gun 21 fixed on the robot arm to the designated welding position, so that the welding gun 21 fixed on the lower electrode arm 13 The lower electrode 12 is in close contact with the workpiece 11 . The robot controller 1 transmits the command to control the movement of the upper electrode 9 to the servo motor 6 through the signal optical cable 4, and the servo motor 6 controls the upper electrode 9 fixed on the upper electrode arm 8 to move to the designated position at a predetermined speed through the transmission device 7. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com