Automatic dredging method and device for pneumatic convey system

A pneumatic conveying system and automatic technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of dangerous places for knocking or dismantling pipelines, long troubleshooting time, raw material shortages, etc., to avoid unnecessary problems. The effect of standardizing operation, improving production efficiency and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

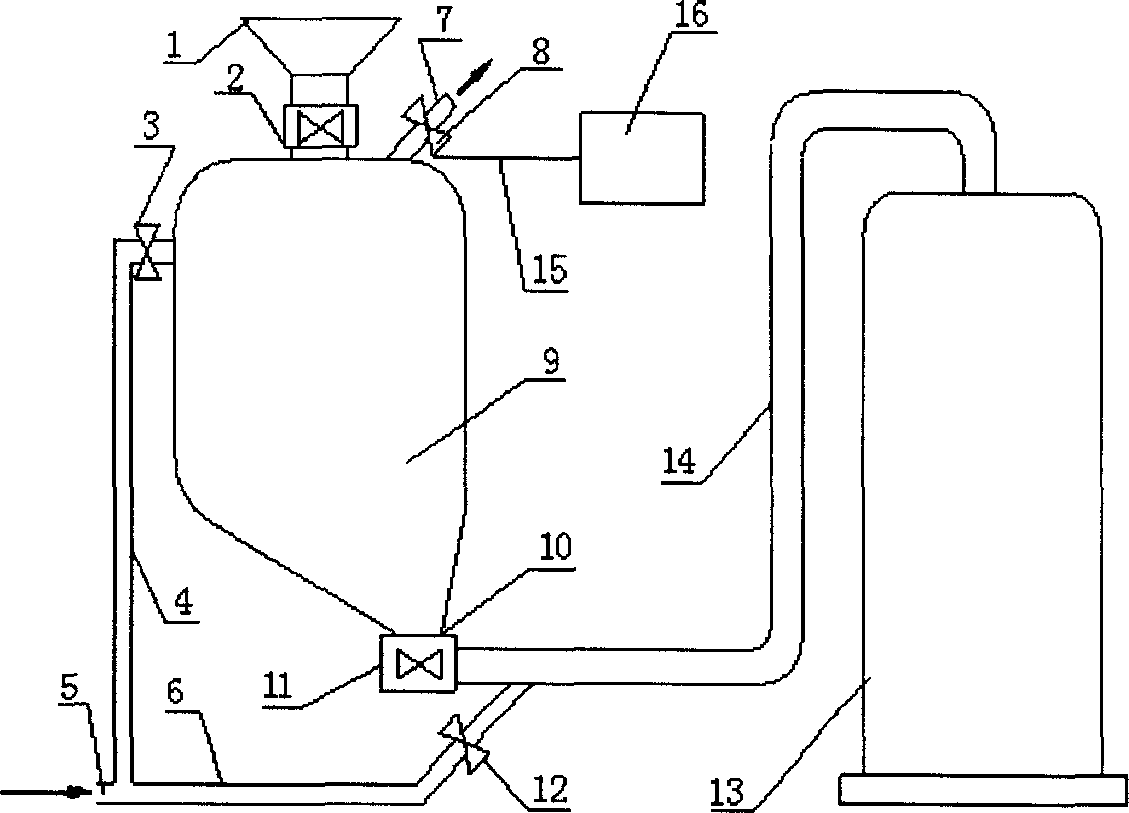

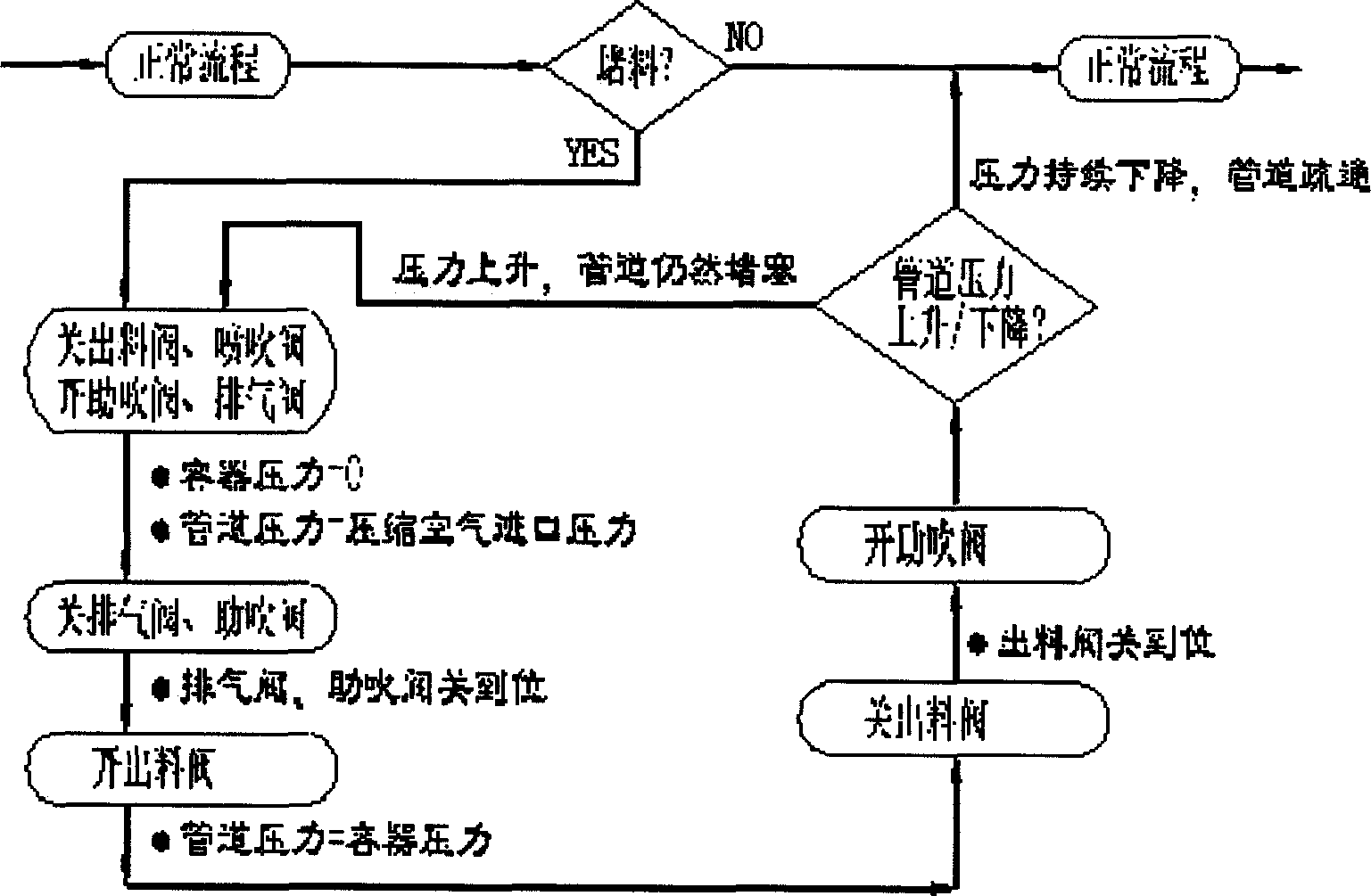

[0017] Embodiments of the present invention: design the volume of the pressure vessel and the specifications of the pipeline according to the delivered output, select and determine the parameters of compressed air, various valves and other components, connect the pressure vessel 9 with the feed valve 2, and the feed valve 2 is connected to the feed port 1, the exhaust pipeline 7 is connected to the pressure vessel 9, the exhaust valve 8 is connected to the exhaust pipeline 7, the compressed air pipeline 4 and the compressed air pipeline 6 are connected at the compressed air inlet 5, and the The blowing valve 3 is connected to the compressed air pipeline 4, and the auxiliary blow valve 12 is connected to the compressed air pipeline 6. The compressed air pipeline 4 is connected to the upper part of the pressure vessel 9, and the lower part of the pressure vessel 9 has a discharge port 10, and the discharge port 10 It is connected with the discharge valve 11, the discharge valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com