Speaker diaphragm and method for manufacturing the same

A vibrating plate and speaker technology, applied in the direction of sensors, diaphragm structures, sensor types, etc., can solve the problems of influence, difficulty in adjustment, and high homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

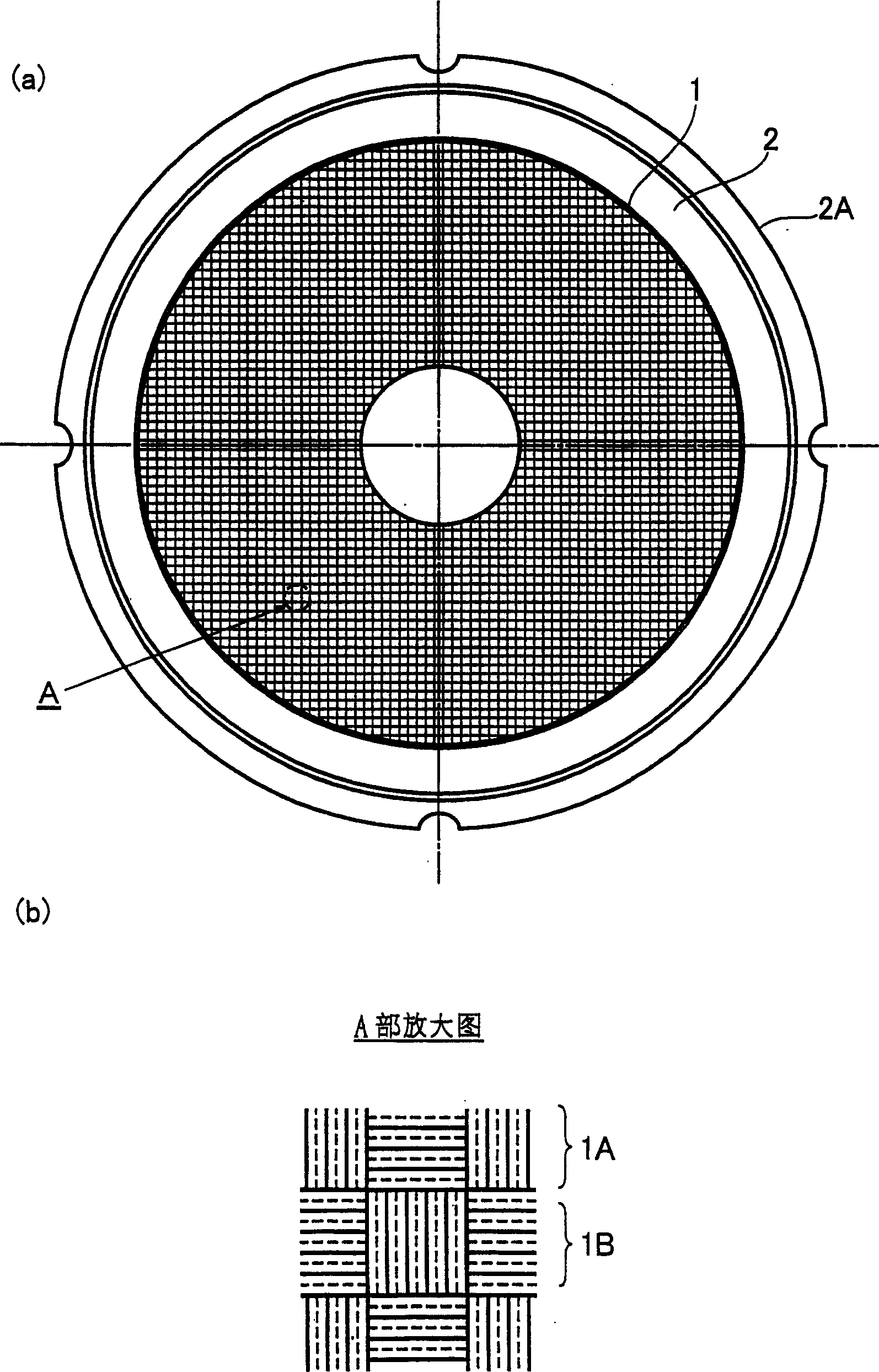

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a plan view and a partially enlarged view of a speaker diaphragm according to an embodiment of the present invention. figure 1 (a) is a plan view illustrating a conical vibrating plate. An edge 2 is formed around the diaphragm 1 , and an attachment portion 2A for connecting to a speaker frame is formed on the outer edge of the edge 2 . In an embodiment of the present invention, the vibrating plate 1 is based on a woven fabric formed by mixing natural fibers with chemical fibers.

[0018] figure 1 (b) shows an enlarged view of part A of the vibrating plate 1 . As an example, the vibrating plate 1 is formed by weaving warp yarns 1A and weft yarns 1B, and natural fibers (indicated by wavy lines) are mixed in both the warp yarns 1A and the weft yarns 1B. However, it is not limited to this example, and natural fibers may be mixed in the warp 1A or the weft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com