Packing box and package conformation article

A packaging box and main body technology, which is applied in the field of packaging boxes and packaging structures, can solve problems such as damage to the paste layer, adverse effects on the shape and performance of the plasma display panel, and misalignment of the end face, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] Hereinafter, the present invention will be specifically described through embodiments with reference to the drawings.

[0090] In addition, in this embodiment, if Figure 8 As shown above, the wound body 60 including the cylindrical core 61 and the film 62 for forming electronic device parts wound on the core 61 can be exemplified as the "rolled body" in the present invention. In addition, the wound body 60 may be prepackaged in a clean bag made of polystyrene and then stored in the packing box of the present invention. In addition, at this time, the cleaning bag is preferably sealed with a cap made of polypropylene or the like having a size suitable for the inner diameter of the terminal protrusion of the core 61 . The cover also has a reinforcing effect on the winding core 61 .

[0091] (1) Composition of packing box

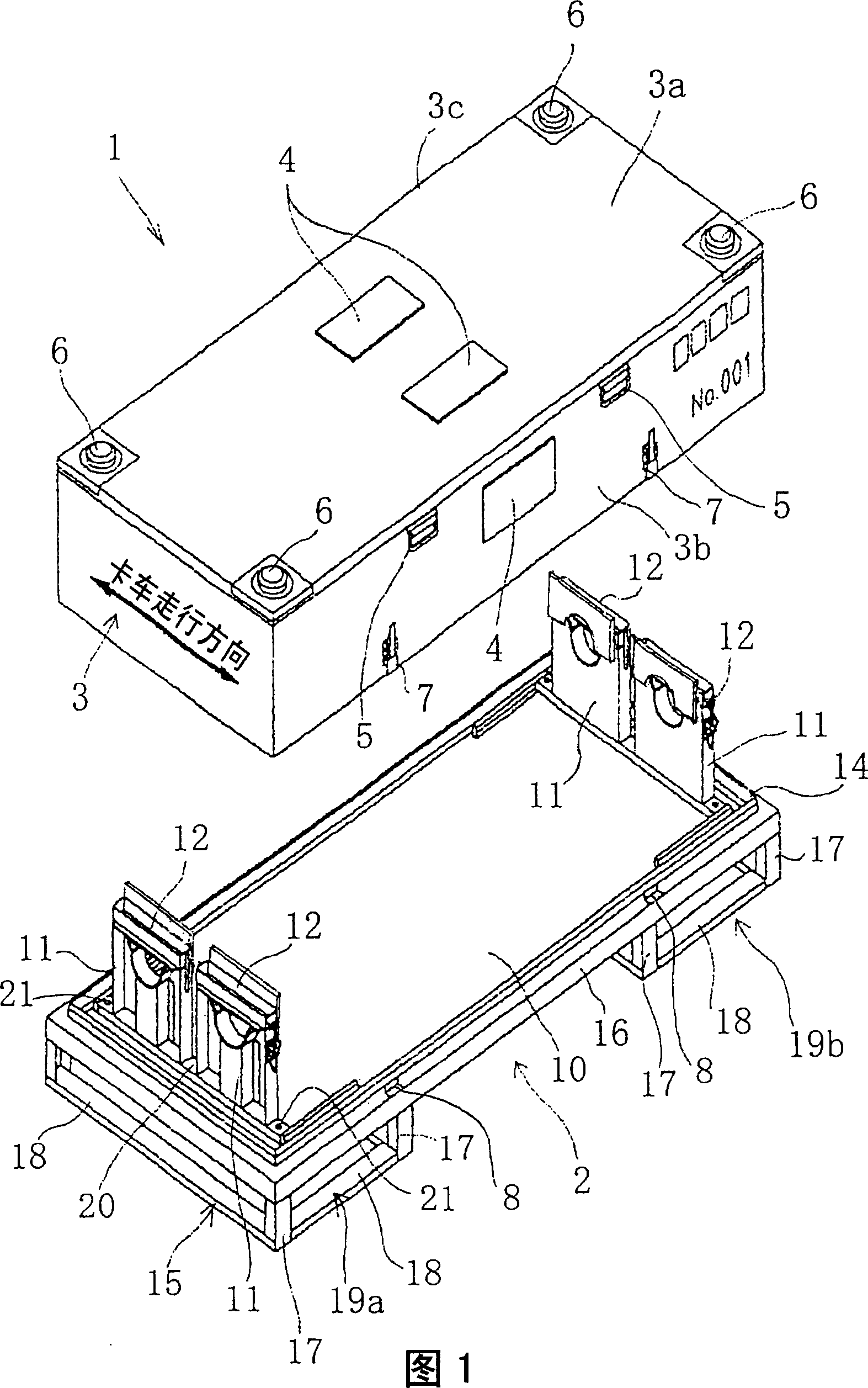

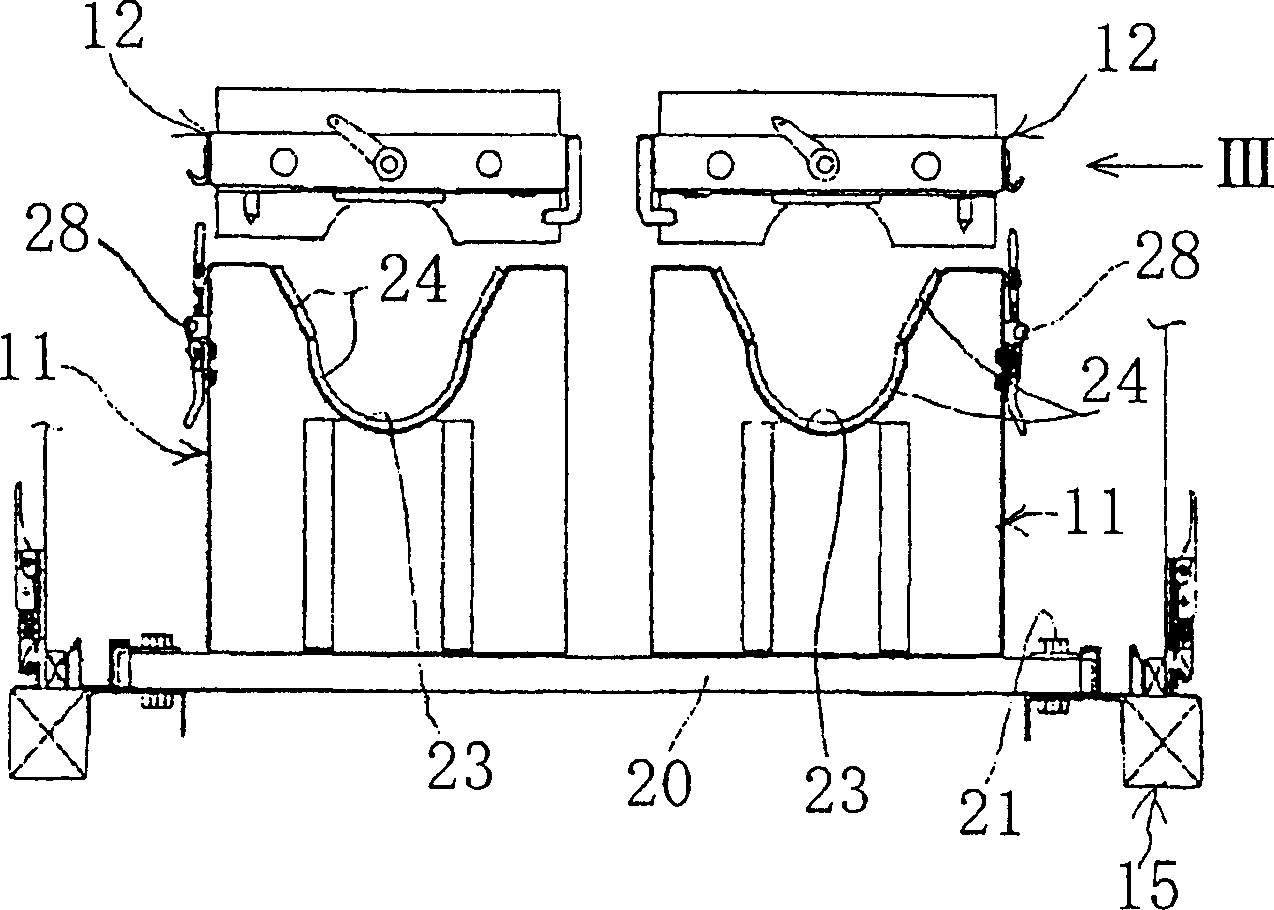

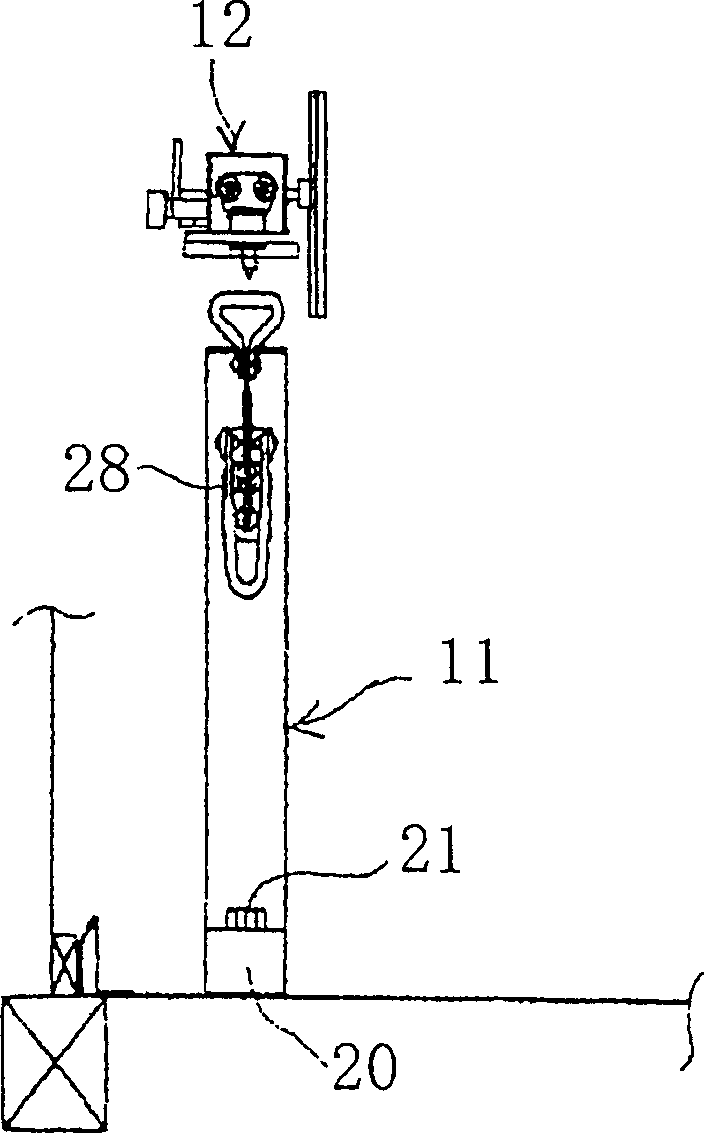

[0092] As shown in FIG. 1 , the packaging box 1 according to this embodiment has a box body 2 and a cover body 3, and a plurality of (two in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com