HDPE, PVC plastic compound winding pipe

A technology of winding pipe and composite glue, which is applied in the sewer pipe system, indoor sanitary pipe installation, waterway system, etc., can solve the problems of low strength and high cost, and achieve good seismic performance, excellent liquid flow, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

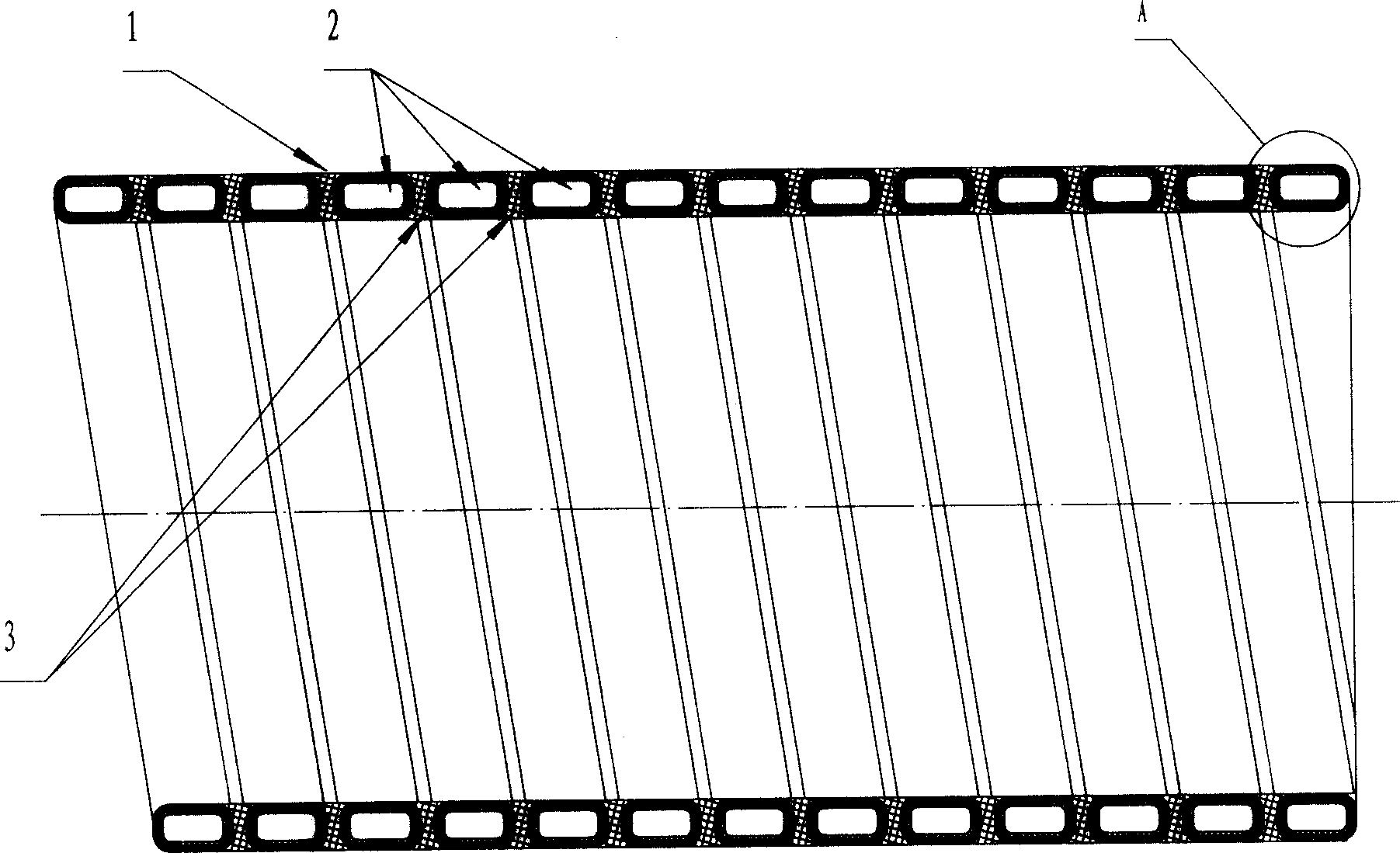

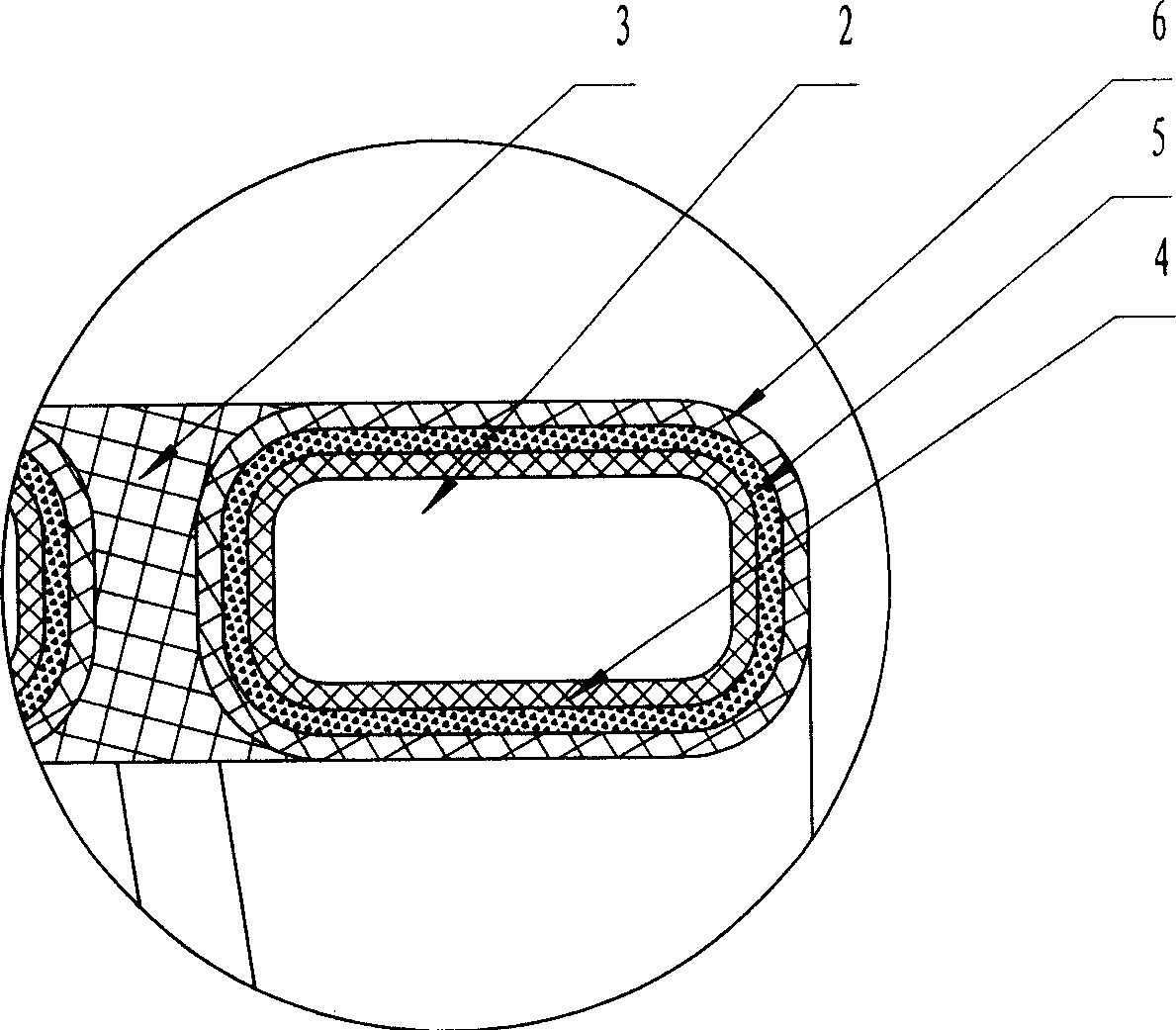

[0019] Such as figure 1 , 2 As shown, the HDPE and PVC plastic-plastic composite winding pipe in this embodiment has a winding pipe body 1, and the pipe wall of the winding pipe body is composed of a spirally wound rectangular tubular hollow strip 2 and a HDPE plastic filler 3, The HDPE plastic filling body 3 is bonded and filled in the side wall gap between the spirals of the helically wound rectangular tubular hollow strips 2, which is characterized in that the pipe wall of the rectangular tubular hollow strips is from the inside to the The outside is composed of a PVC plastic layer 4, a composite adhesive layer 5 and an HDPE plastic layer 6, and the composite adhesive layer 5 is sandwiched between the PVC plastic layer 4 and the HDPE plastic layer 6 and is connected to the PVC plastic layer 4 and the HDPE plastic layer 6. The HDPE plastic layer 6 is glued together.

[0020] When making the HDPE and PVC plastic-plastic composite winding pipe in this embodiment, firstly, a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap