Method for determing cam outline shape of nonimpact constant flow double-plunger pump

A cam profile, double plunger pump technology, applied in the mechanical field, can solve the problems of discontinuous piston acceleration and unfavorable high-speed operation of the plunger pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments are provided below in conjunction with the method of the present invention:

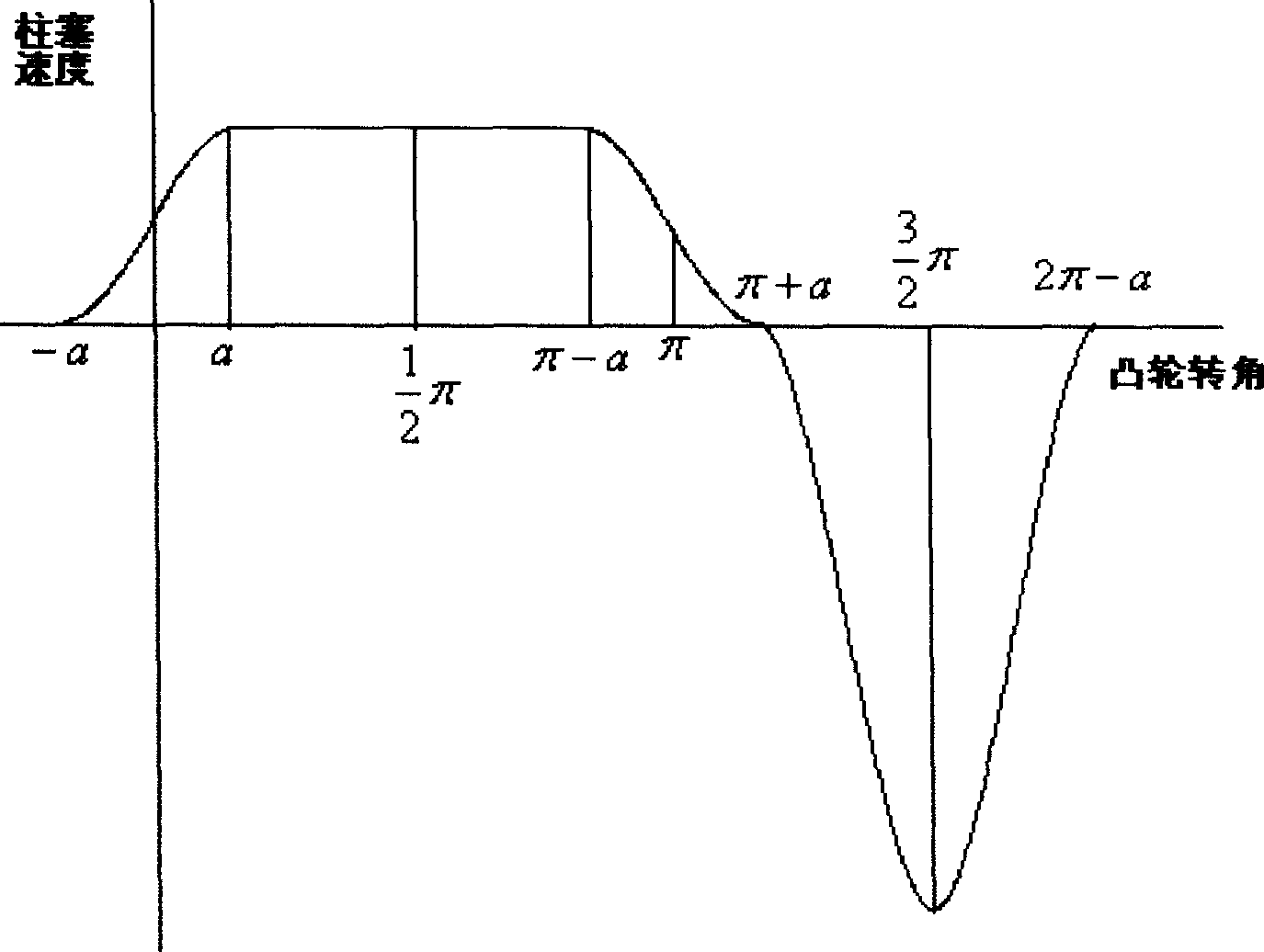

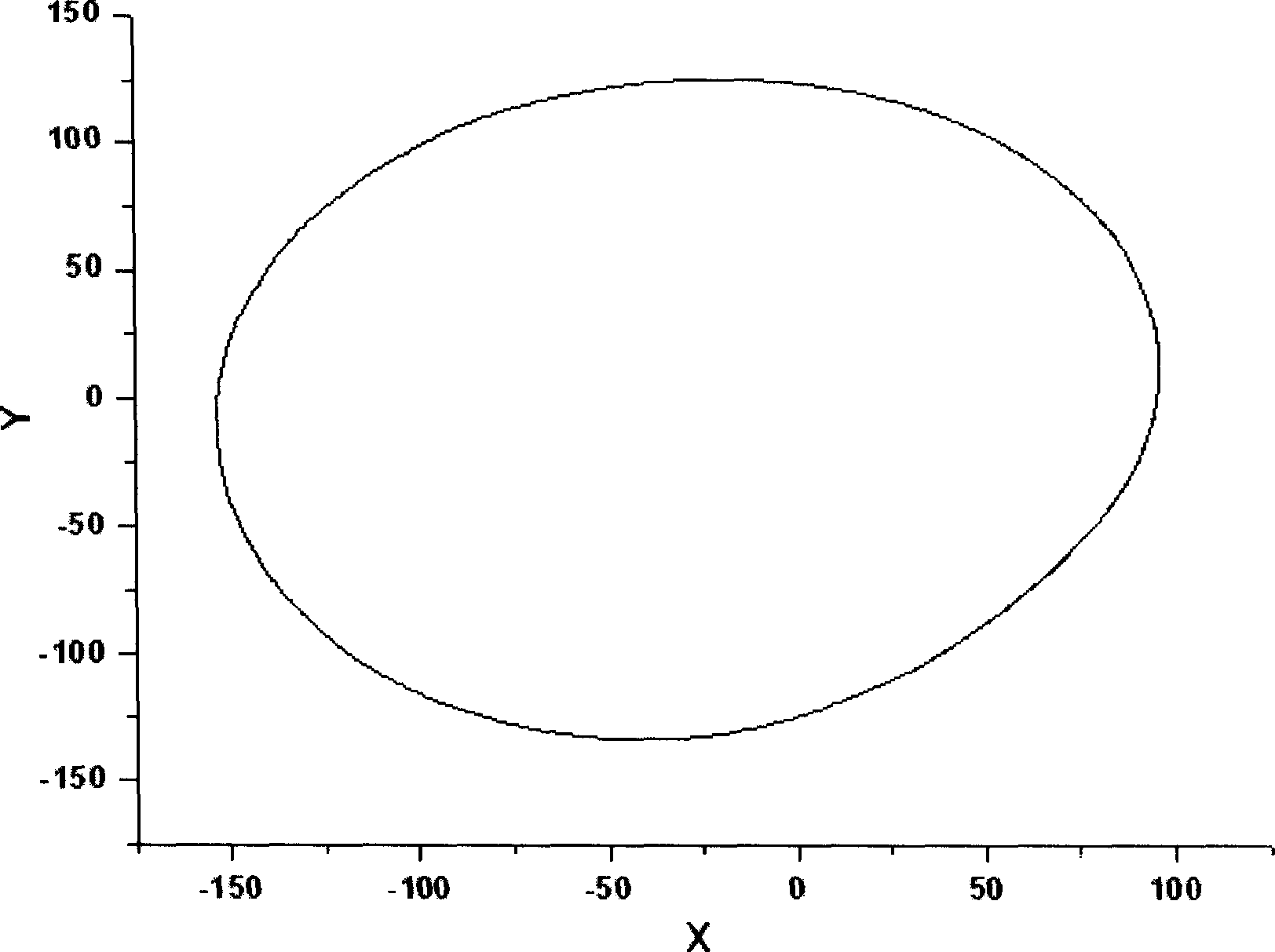

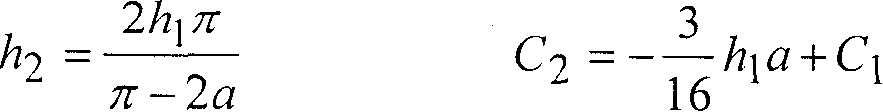

[0040] For a hydraulically driven cam, select h according to the flow rate and cam size requirements 1 =20,C 1 =50, when the speed change transition parameter is a=π / 6, the cam profile shape is obtained by applying the 5-stage cam profile expansion function provided by the present invention. Its plunger speed is as figure 1 As shown, the cam shape is as figure 2 As shown, when the cam speed is 1500r / min, the plunger area is 100πmm 2 , the plunger pump can output a constant flow of 59.2 liters / min. The plunger pump has no pulsation in flow rate and continuous plunger acceleration, which can realize stable high-speed operation.

[0041] In practical application, the plunger pump has the following points:

[0042] 1) It is beneficial to improve the operating efficiency of the plunger pump. Because the acceleration of the plunger is continuous, there is an example of high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com