Refrigerant compressor

A technology for compressors and refrigerants, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of mechanical stress on the piping system, and achieve the effect of mode restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

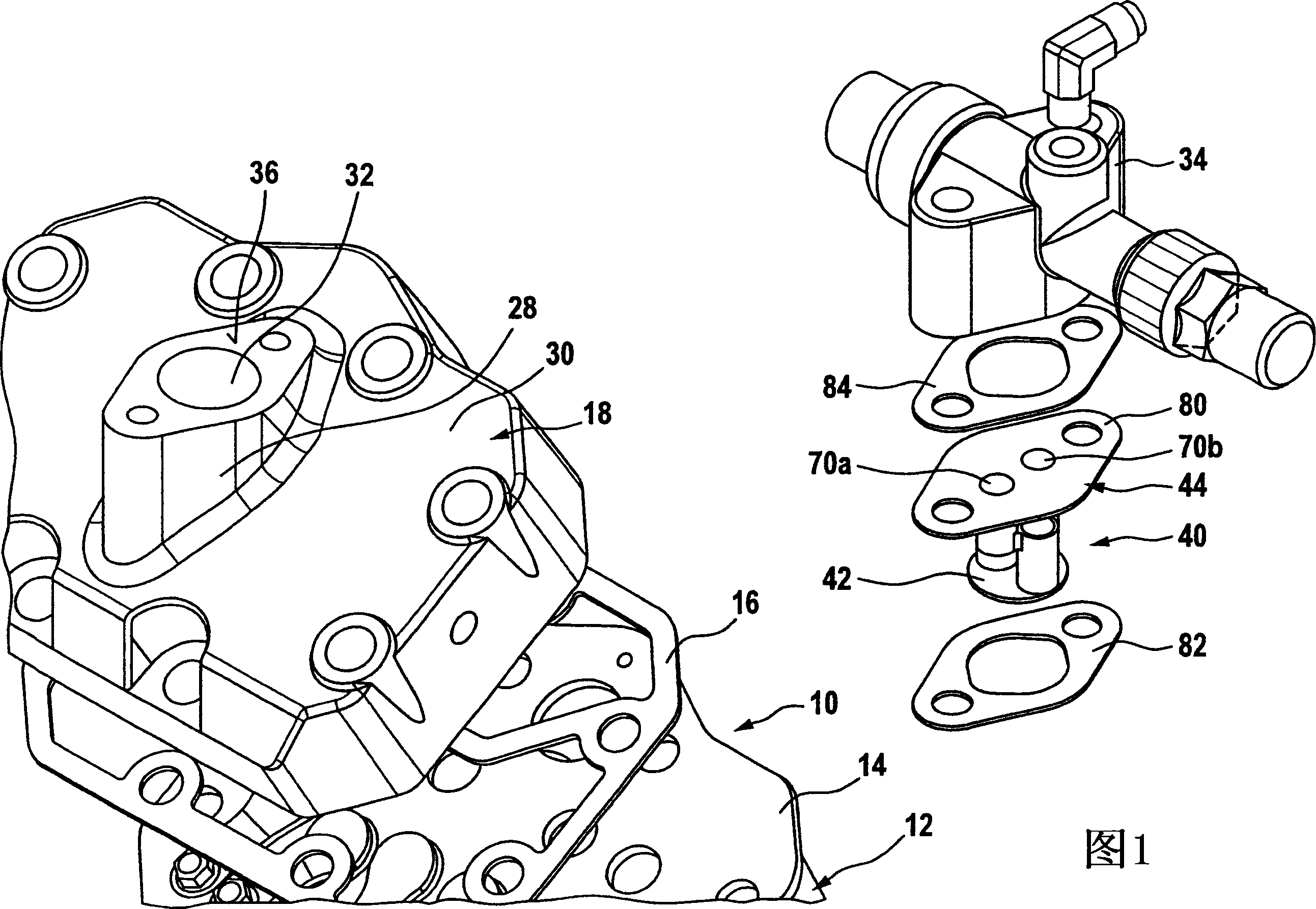

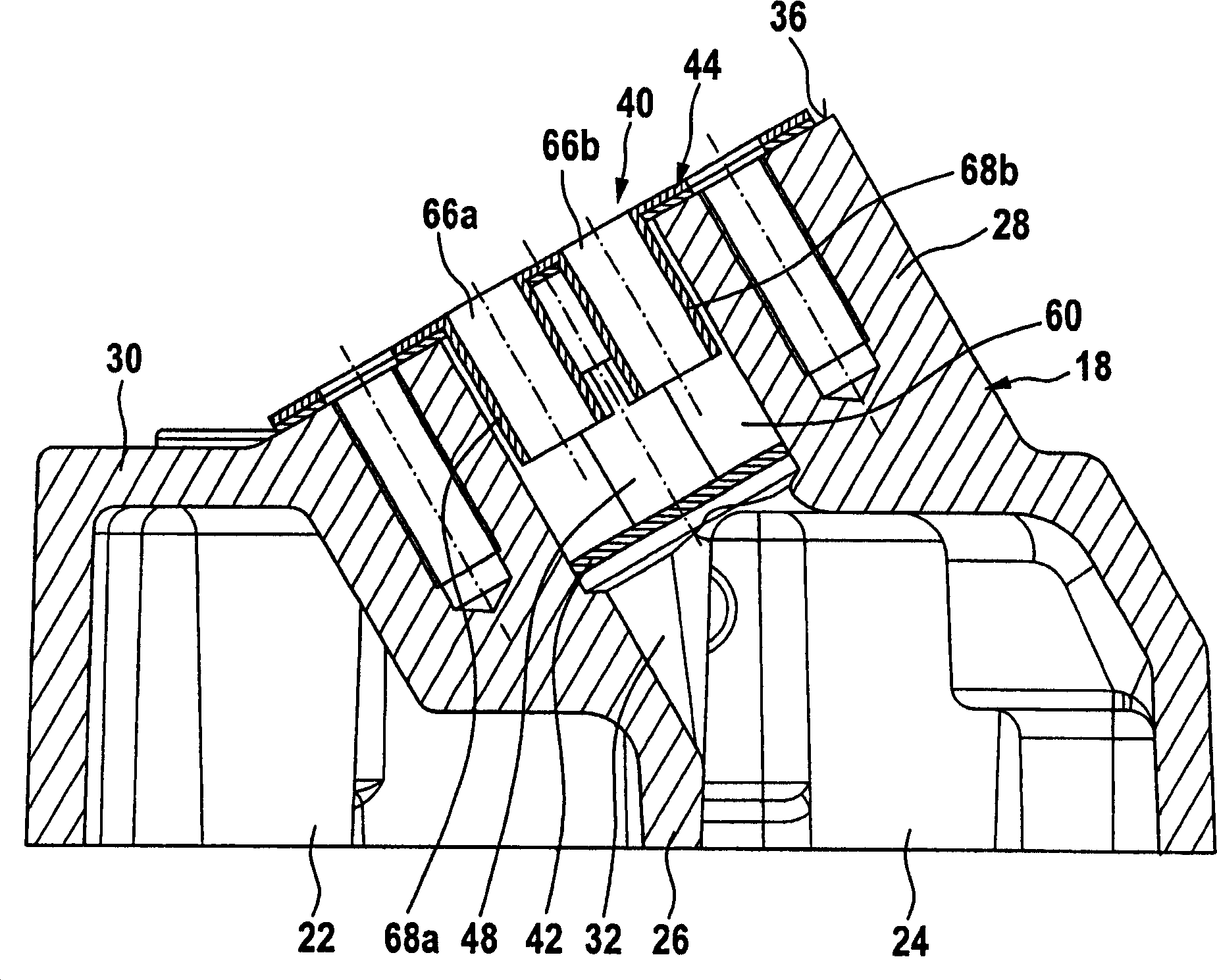

[0041] The volumetric compressor designed according to the present invention is a piston compressor, and its compressor cylinder 10 is partially shown by Fig. 1; A cylinder head 18 is arranged thereon, which is sealed by means of a gasket 16;

[0042] Furthermore, the cylinder head 18 is provided with a short connecting pipe 28, which is preferably arranged in the cover 30 of the cylinder head 18, so as to form an outlet channel 32 through which the compressed refrigerant can flow from the outlet chamber 24 out and into the fitting 34.

[0043] This nipple 34 can be placed on the connecting surface 36 of the short connecting pipe 28 and can be mounted thereon.

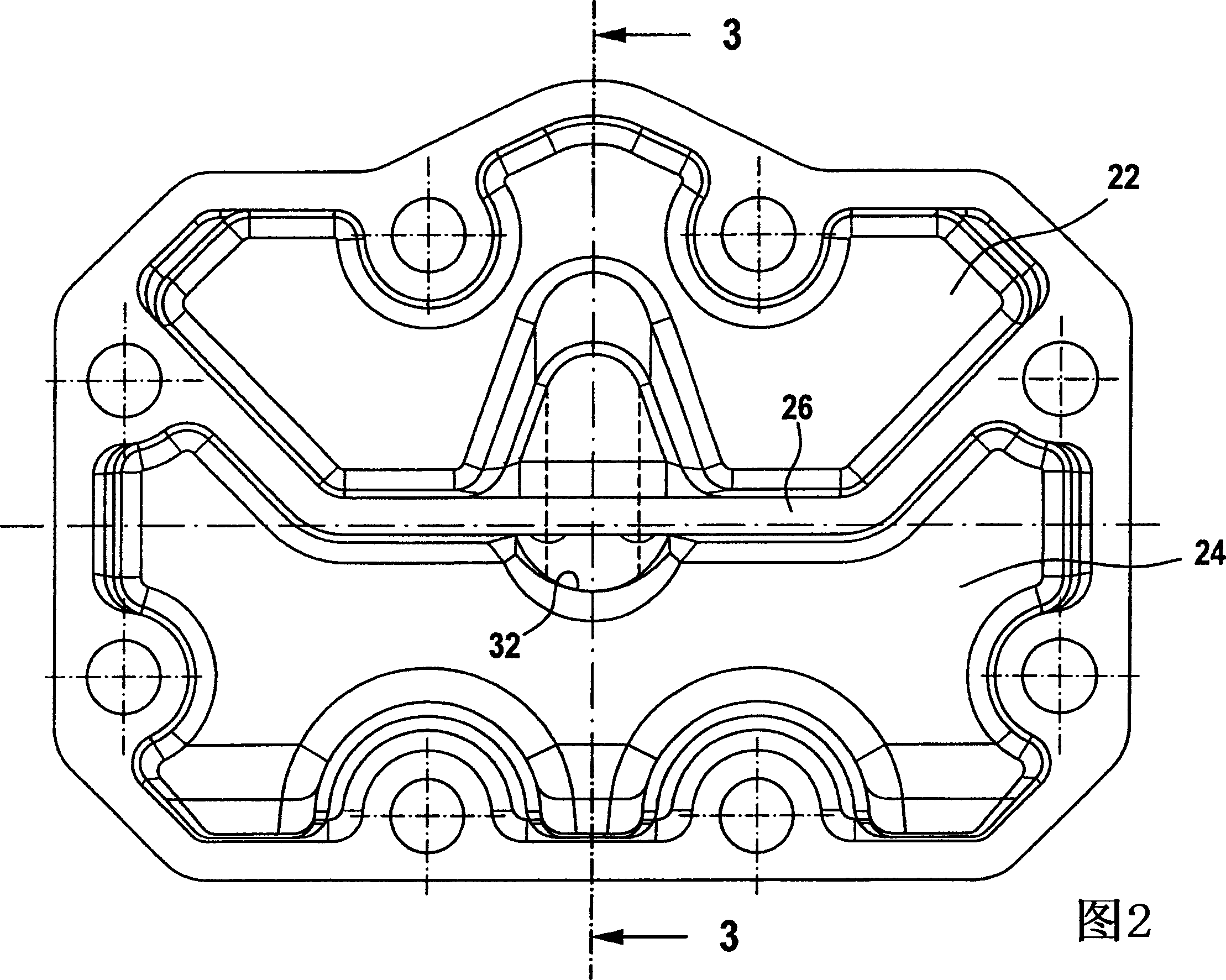

[0044] As shown in Fig. 1 to Fig. 6, the whole of the damping part is represented by a mark 40; in order to damp the pulsation in the refrigerant flow flowing out from the output chamber 24, the damping part 40 with an inlet baffle 42 and an outlet baffle 44 The connecting channel 32 is inserted into the short connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com