A closure

A technology of capping and sealing strip, applied in the direction of caps, closures, bottle/container caps, etc., can solve problems such as increased friction and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

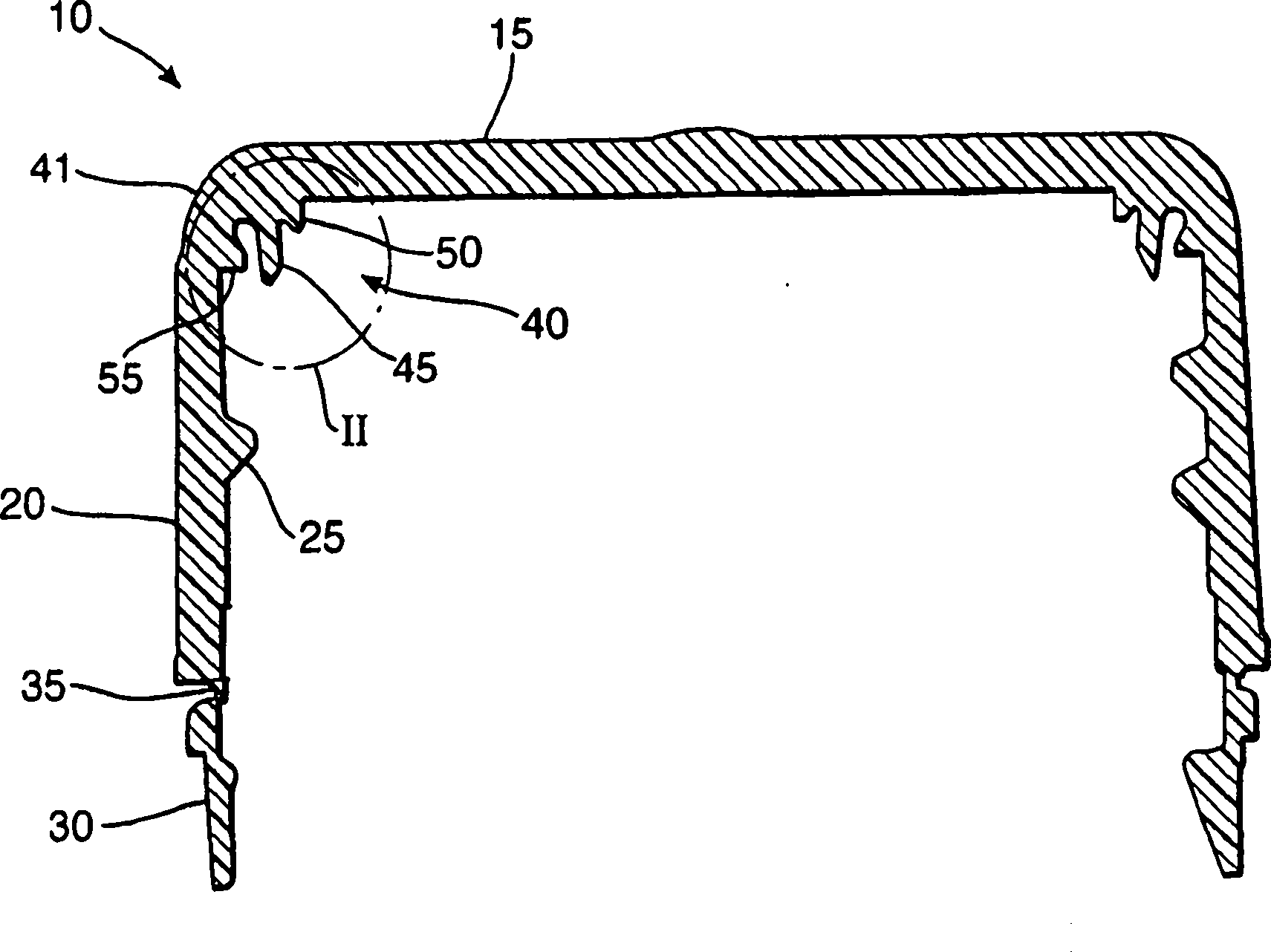

[0026] see first figure 1 , which shows a plastic cover indicated generally at 10 . The cover 10 includes a disc-shaped top plate 15 and a cylindrical side skirt 20 depending from the periphery of the top plate 15 . The side skirt 20 includes internal threads 25 for engaging external threads on a container neck finish (not shown). An anti-tamper strip (or anti-tampering band) 30 is connected to the lower open end of the side skirt portion 20 in a frangible manner by a bridge 35 in this structure, a technique that will be readily apparent to those skilled in the art. familiar. The closure 10 also includes a sealing structure, generally indicated at 40 , in the region of the curved intersection 41 between the top panel 15 and the side skirt 20 .

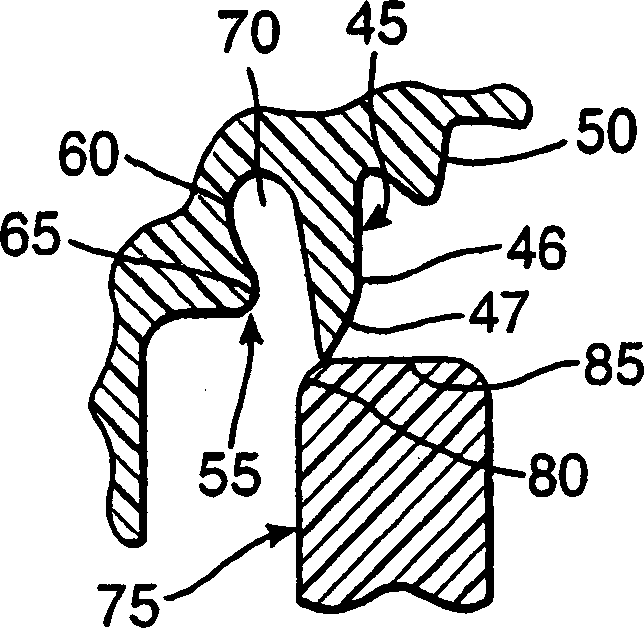

[0027] see you now Figure 2a , which indicates figure 1 In an enlarged view of the structure circled in the center, the sealing structure 40 includes a sealing strip 45 , a top seal 50 and a fitting 55 . In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com