Cooking pot, and methods of preparation

A technology of pot body and pot cover, which is applied in the direction of special materials, applications, cooking utensils, etc. of cooking utensils. Burnt food sticks and prevents damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] The pot body 100 is integrated by a pig iron part 1 and an aluminum alloy part 2 . The aluminum alloy part 2 wraps all or part of the pig iron part 1 to form a double-layer structure, and the specific shape is determined by the shape of the pot body to be manufactured. A coating layer 3 is formed on the surface of the aluminum alloy portion 2 .

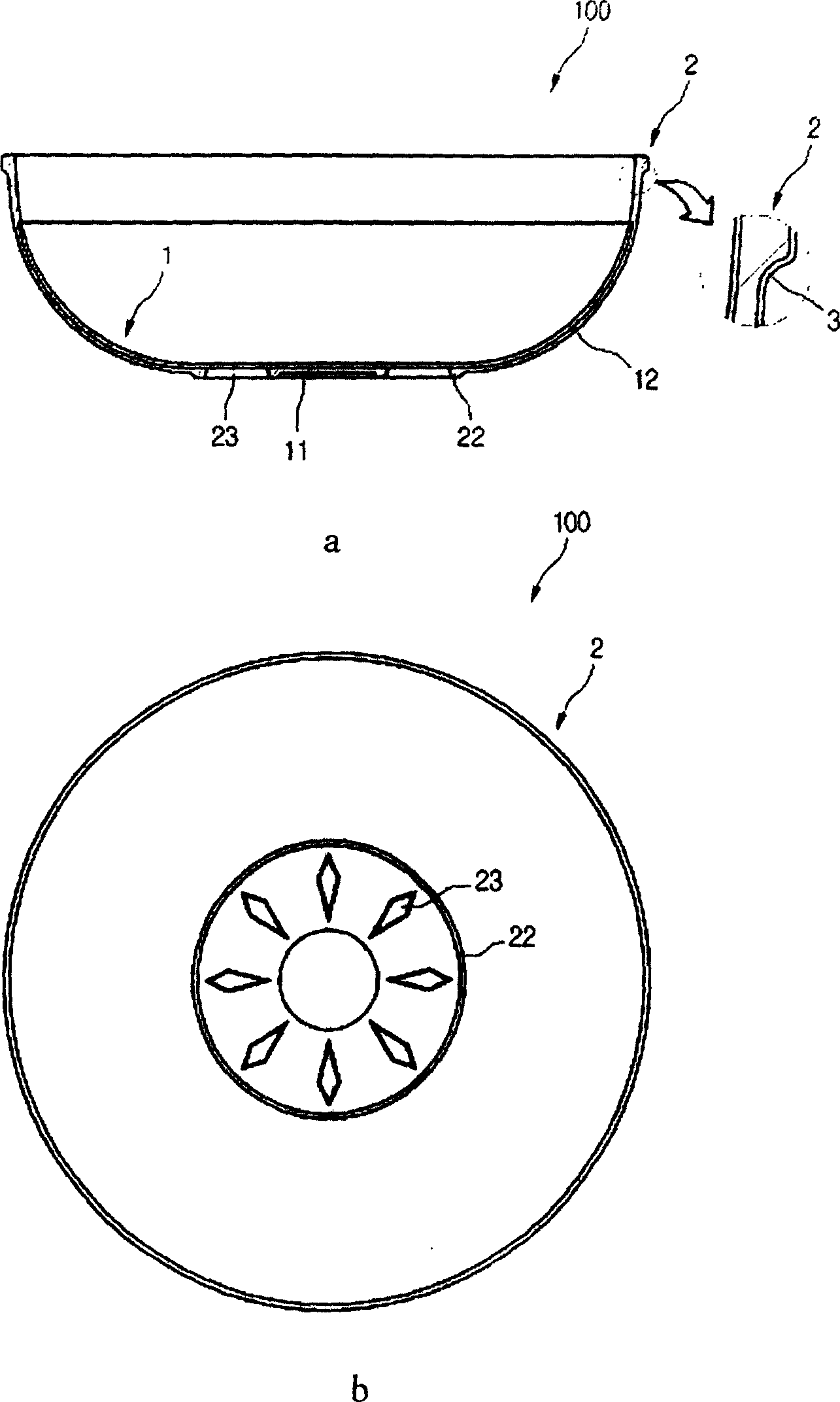

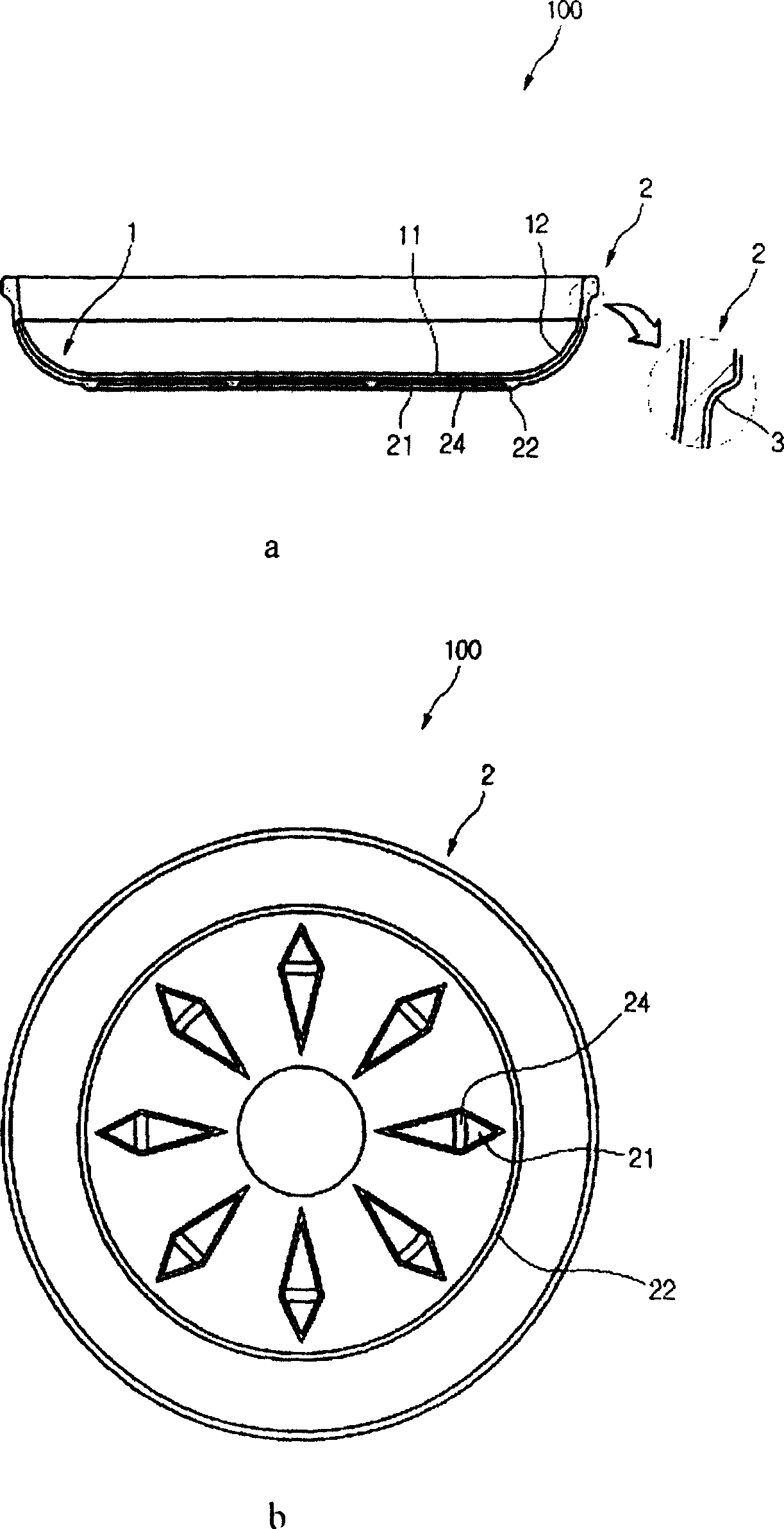

[0026] refer to figure 1 and 2 As shown, in the case of a non-stick pan or a frying plate with a relatively low overall height of the cooking utensil body 100 and a relatively wide shape, the pig iron part 1 adopts a flat bottom 11 plus an upward bending part 12, and the height of the upward bending part Equal to the pot body, the aluminum alloy part 2 wraps the outside of the pig iron part 1 to form a double pot structure.

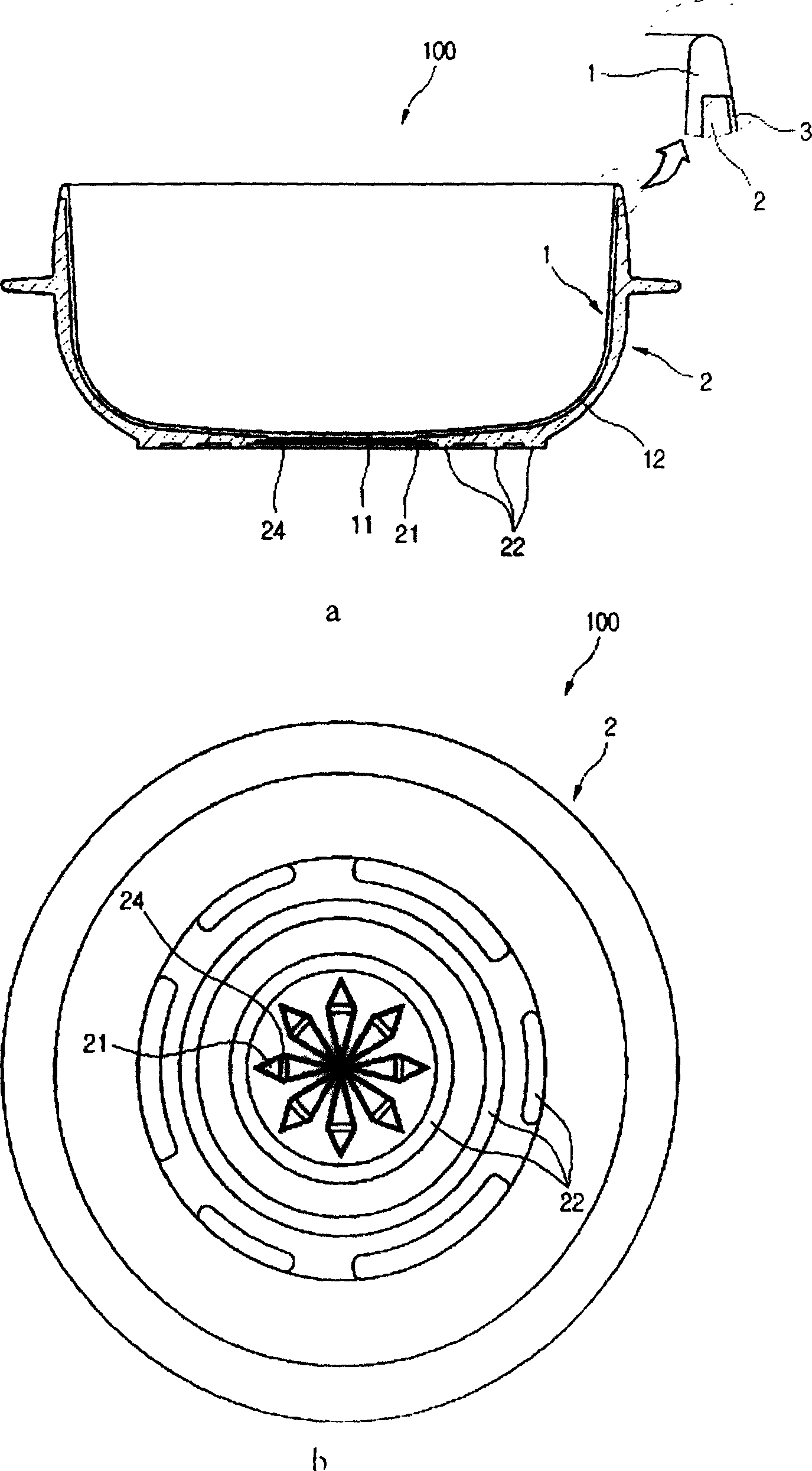

[0027] refer to image 3 and 4 As shown, in the case of the pan and rice cooker whose pot body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com