Generation device of rotating magnetic field in use for controlling welding arc

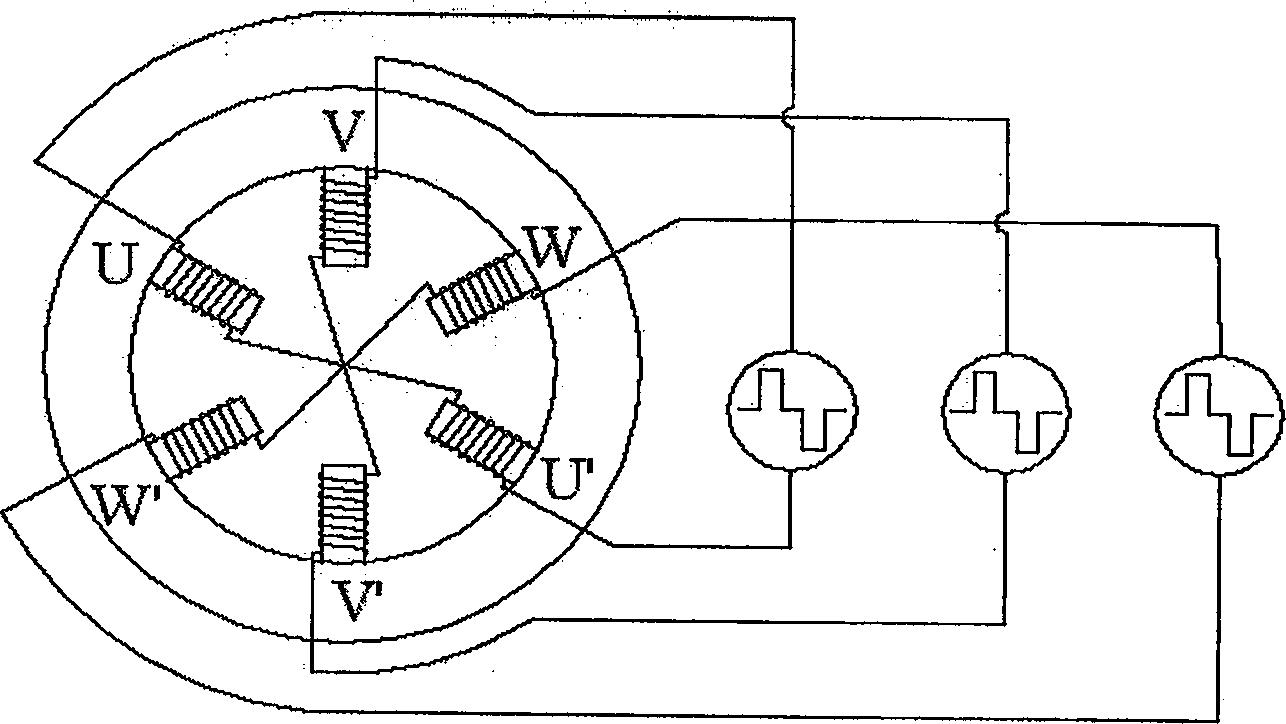

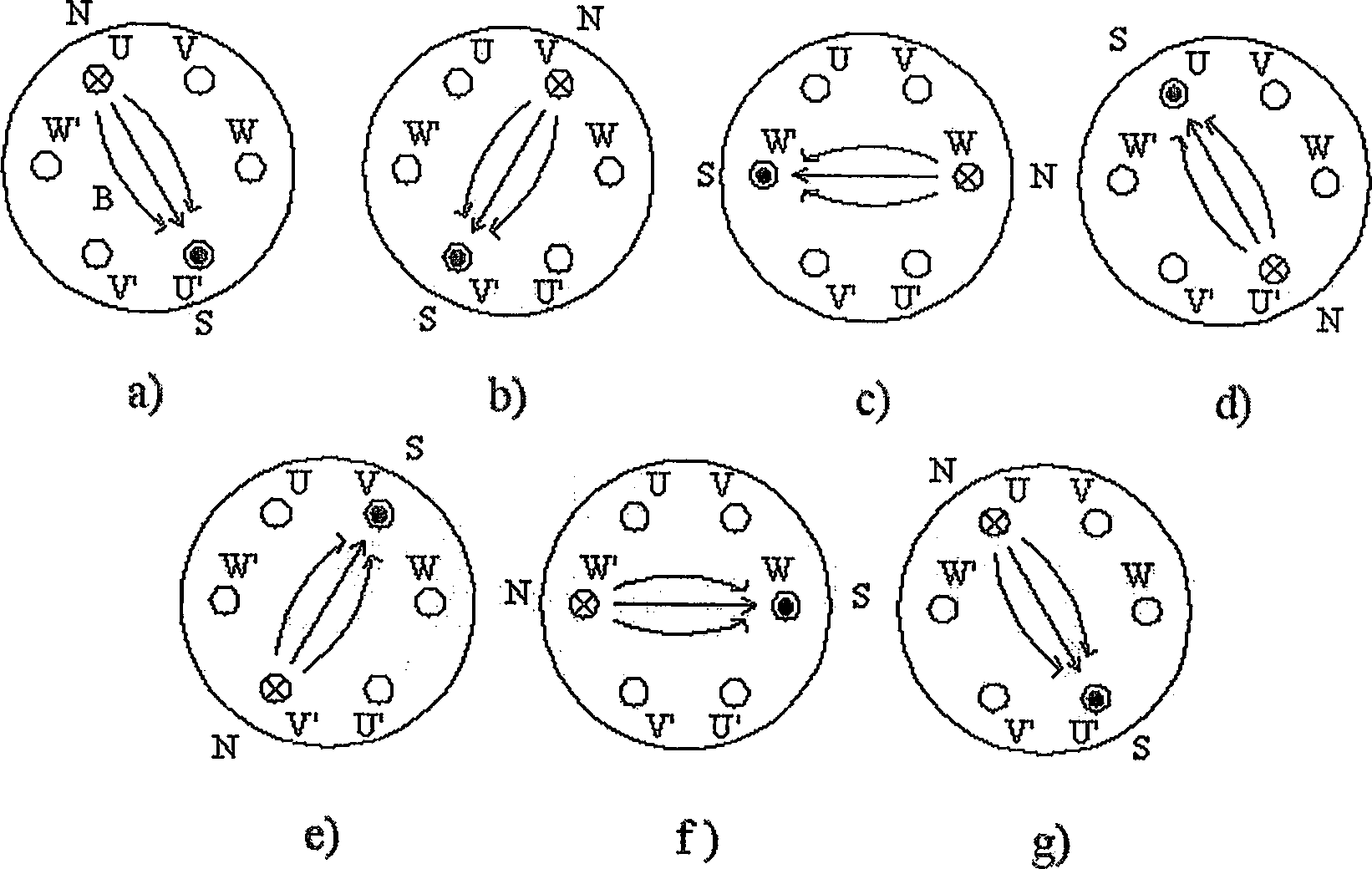

A technology of rotating magnetic field and generating device, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of arc motion restriction, small adjustment range of rotation frequency, and inability to realize independent control of arc rotation frequency, so as to achieve control of welding. Arc movement, improving the effect of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

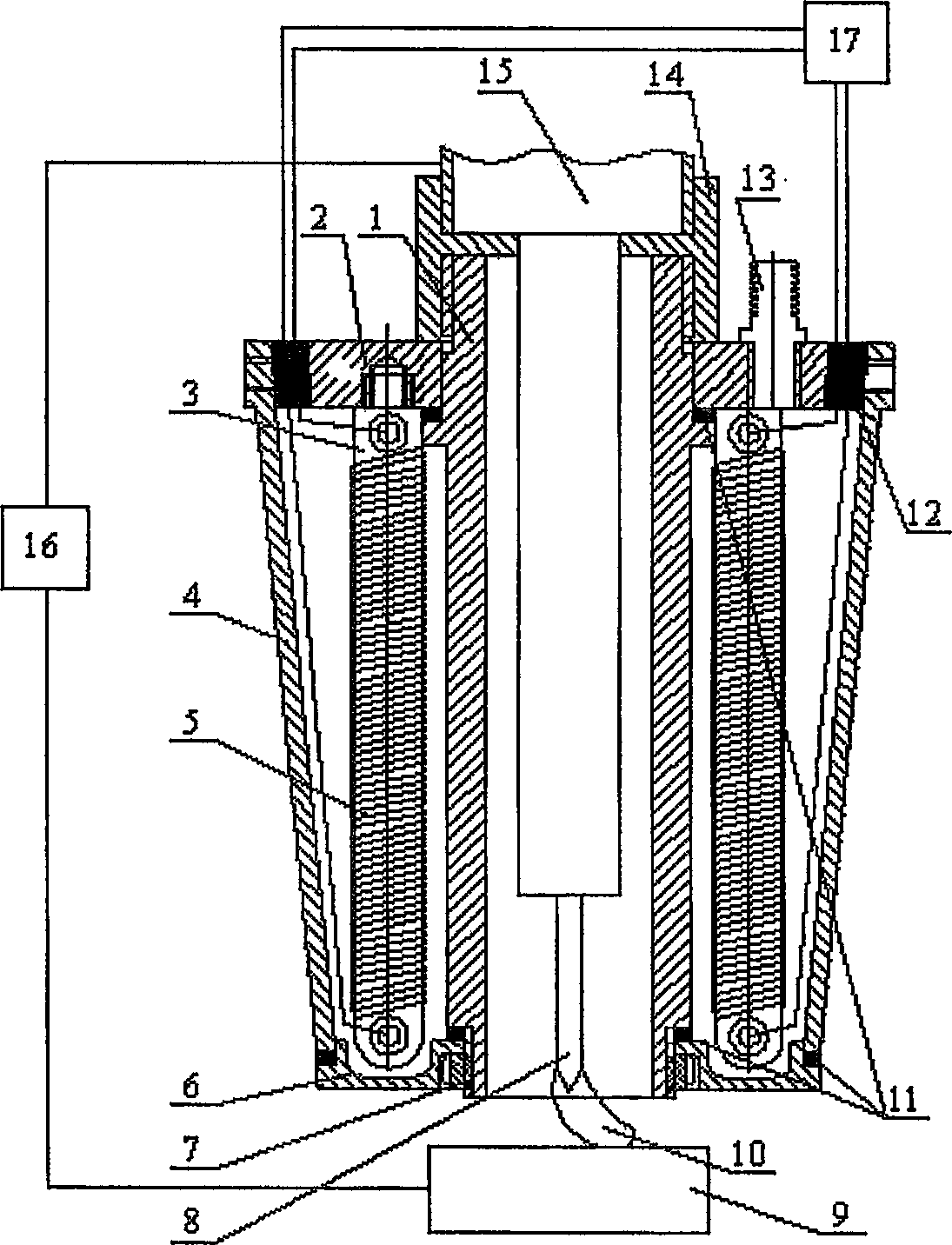

[0023] Specific embodiments of the present invention refer to Figure 3 ~ Figure 5 , the present embodiment mainly includes welding torch 15, magnetic head top cover 2, magnetic head bottom cover 6, magnetic head outer wall 4, magnetic head inner wall 1, excitation coil 5 wound on magnetic post core 3, connecting bakelite ring 14, wherein, connecting bakelite Ring 14 has an internal thread, one side thread is connected with the inner wall 1 of the magnetic head, and the top cover 2 of the magnetic head is pressed onto the outer boss of the inner wall 1 of the magnetic head, and the thread on the other side is connected with the welding torch 15, so that the welding torch 15 is inserted into the inner wall 1 of the magnetic head In the cavity in the center; the magnetic head top cover 2 is connected with the magnetic head outer wall 4 through the annular insulating bakelite ring 12; the magnetic head bottom cover 6 is connected with the magnetic head inner wall 1 through the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com