Method for manufacture prism

A manufacturing method and prism technology, which are applied to prisms, manufacturing tools, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of inclined sidewall errors, cutting errors, and cannot guarantee high-precision angular accuracy, and achieve high angular accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

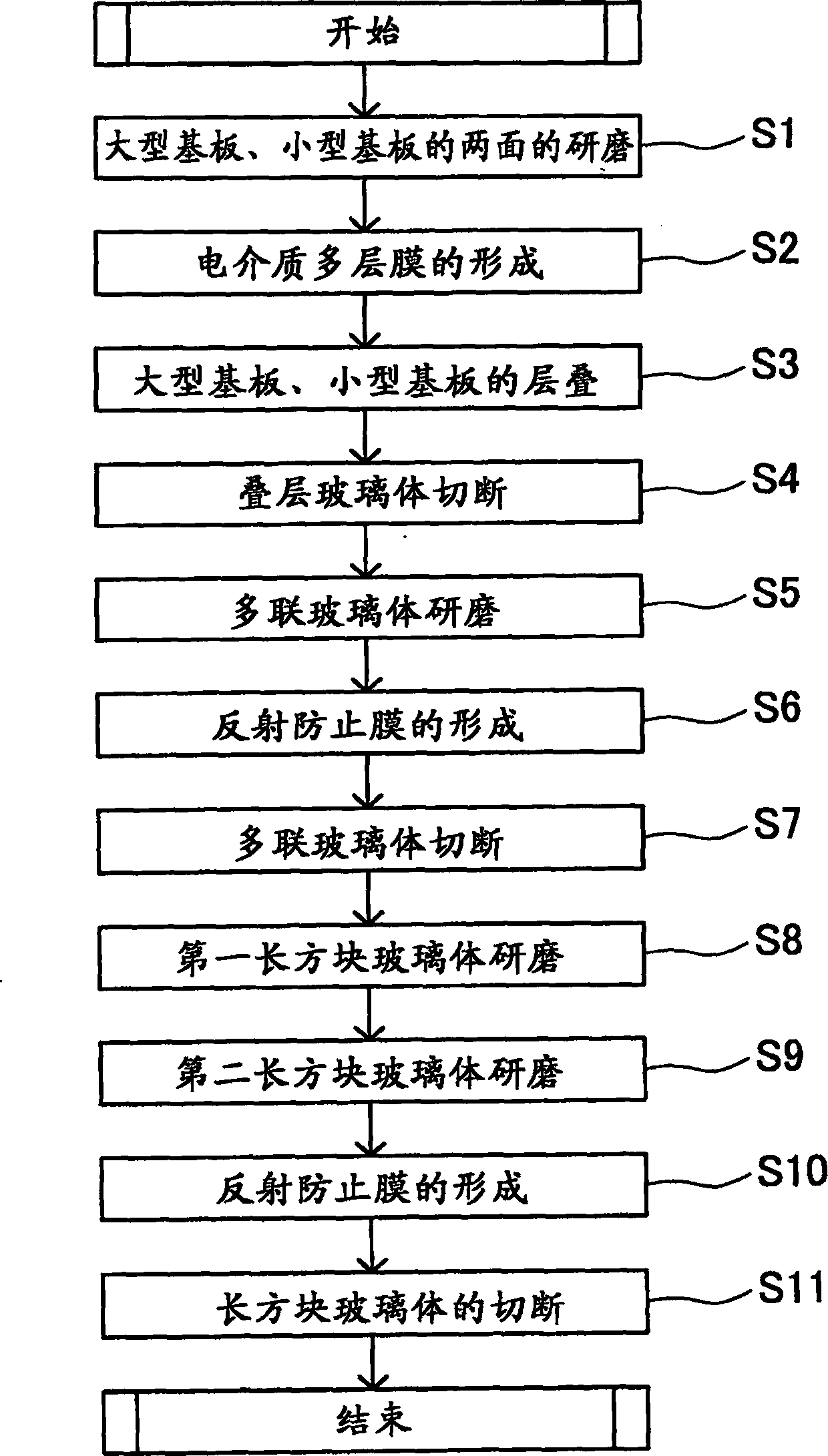

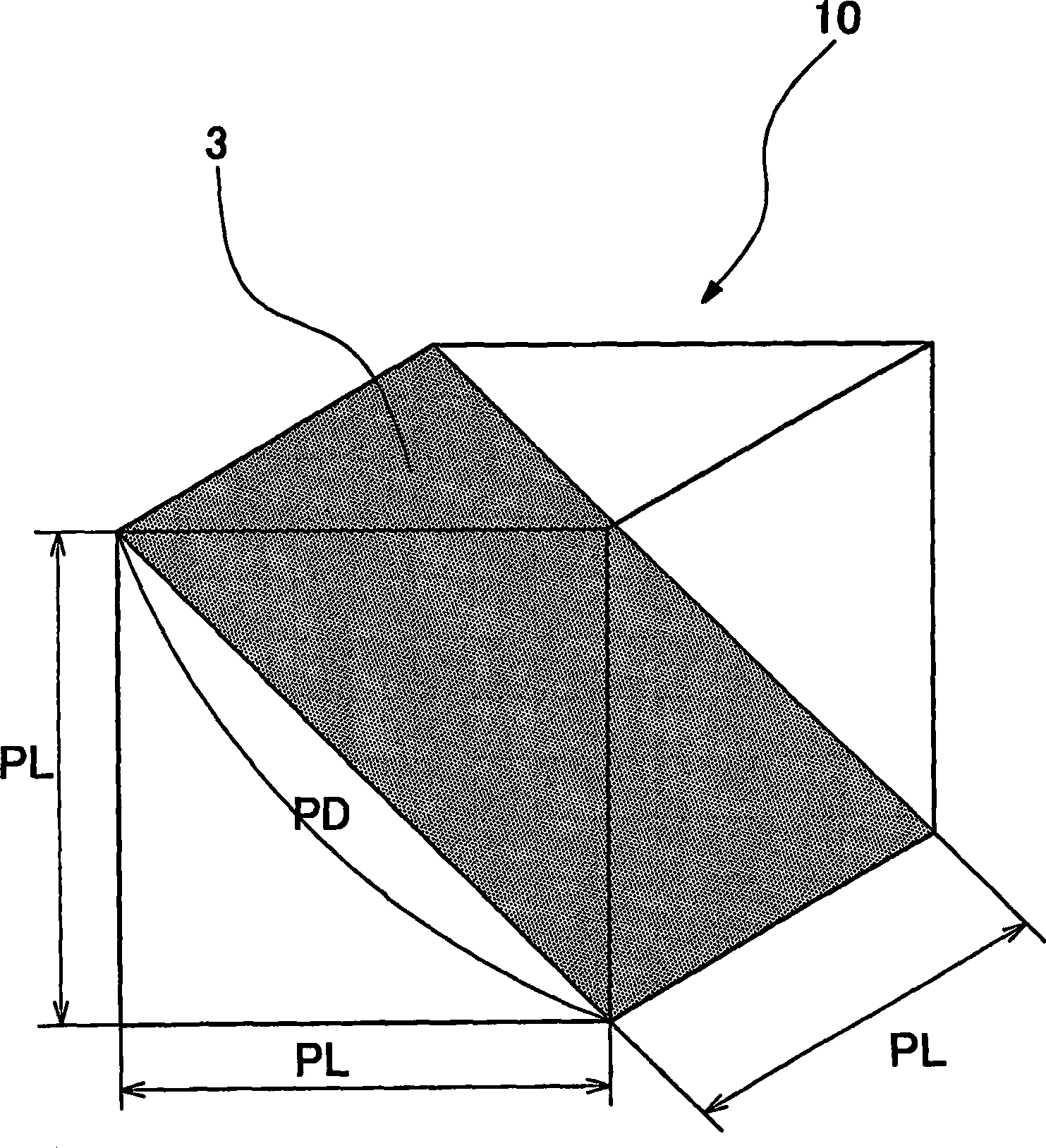

[0024] Below, according to figure 1 The flowchart of Figure 1 illustrates an embodiment of the invention. figure 2 It is the prism 10 finally manufactured. The prism 10 of this embodiment is a cubic optical element with one side PL long, and the dielectric multilayer film 3 is formed at an angle of 45° with respect to the optical axis. Here, in this embodiment, the diagonal length of each surface of the prism 10 (the long side of the surface on which the dielectric multilayer film 3 is formed) is defined as the diagonal length PD of the prism 10 (=PL×). In addition, an antireflection film having an antireflection function is formed on each surface of the prism 10 .

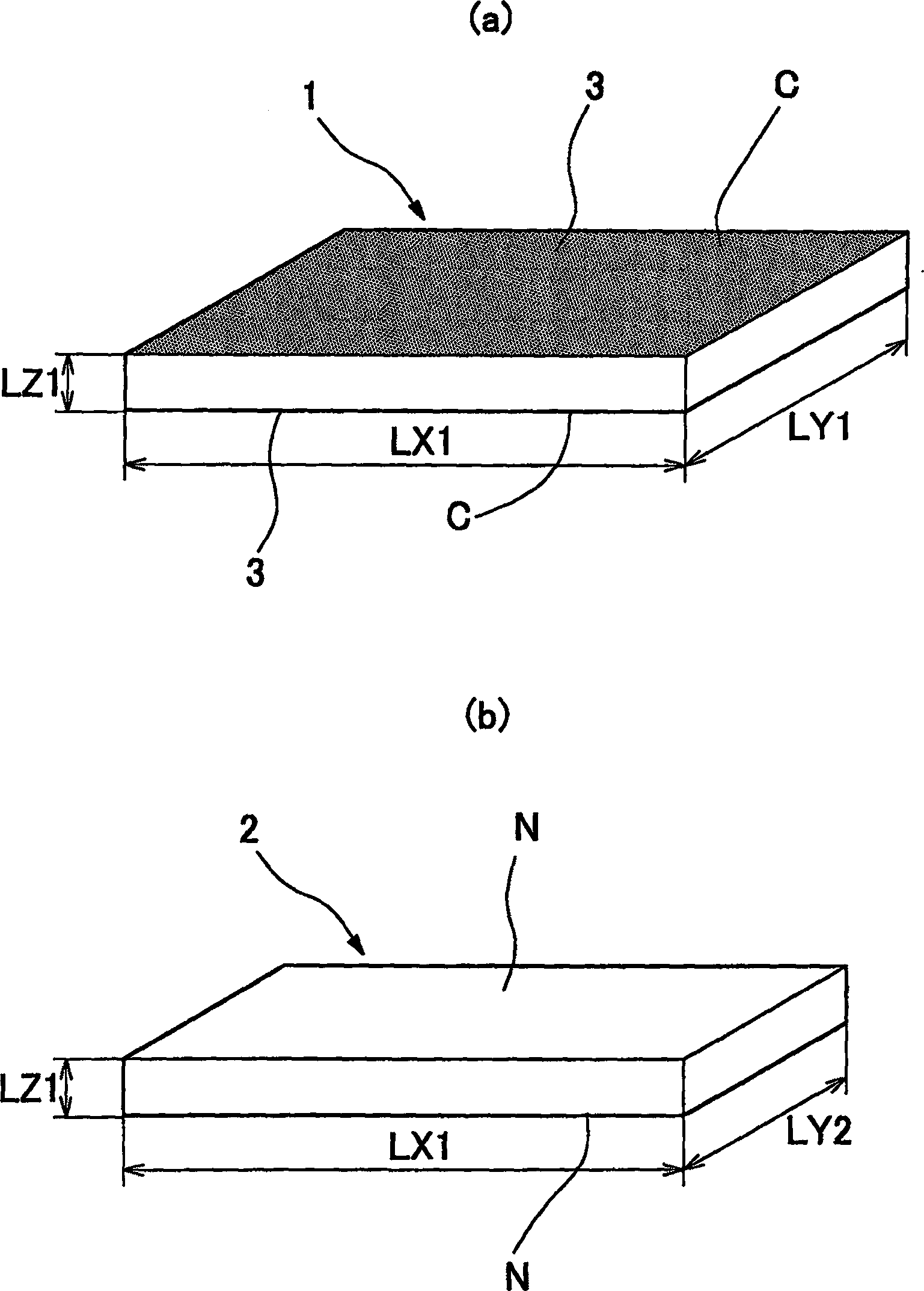

[0025] initially as image 3 As shown, a plurality of two types of flat substrates (substrates such as glass substrates) having different shapes are prepared. exist image 3 (a) shows a large substrate 1 having a long side (width) of LX1, a short side (depth) of LY1, and a thickness of LZ1. image 3 (b) sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com