Device for adjusting and measuring optical module

A technology for commissioning devices and optical modules, applied to transmission monitoring/testing/fault measurement systems, electrical components, electromagnetic wave transmission systems, etc., can solve problems such as time-consuming, low production efficiency, and high cost of functional single boards, and achieve The effect of reducing manual operations, improving production efficiency, and reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The core technical content of the present invention is to realize digital commissioning for optical modules of various rates, and to realize a certain degree of automatic production.

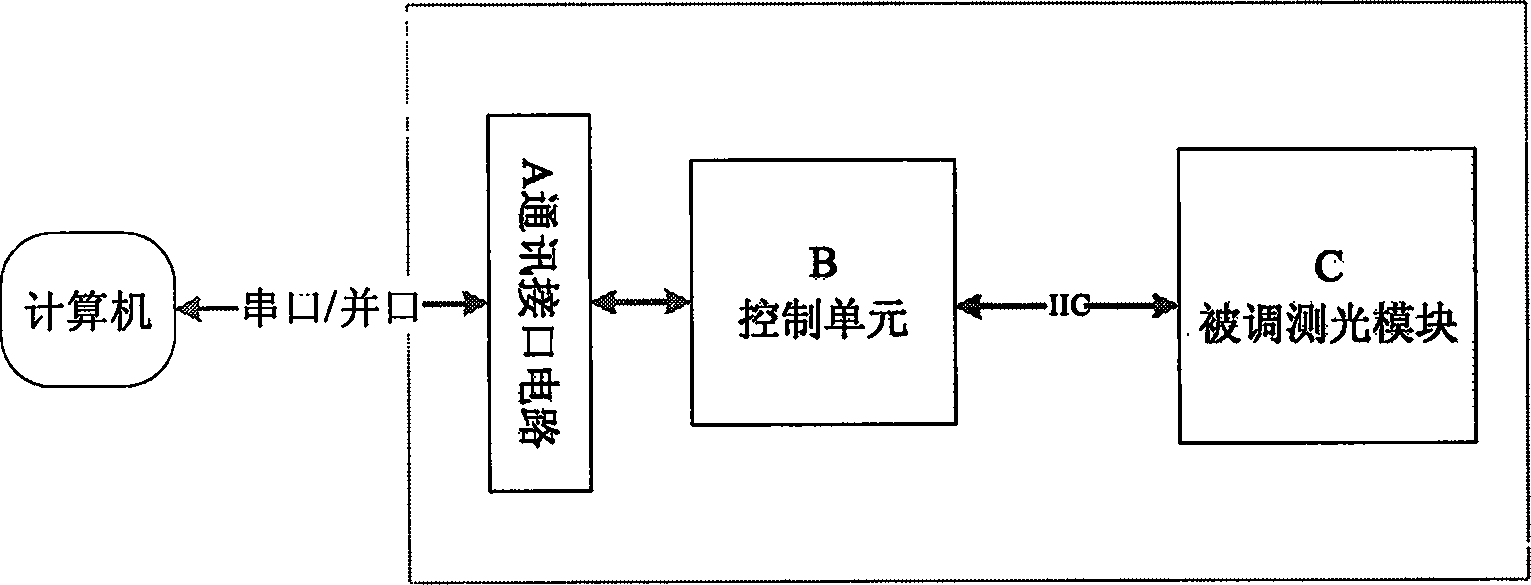

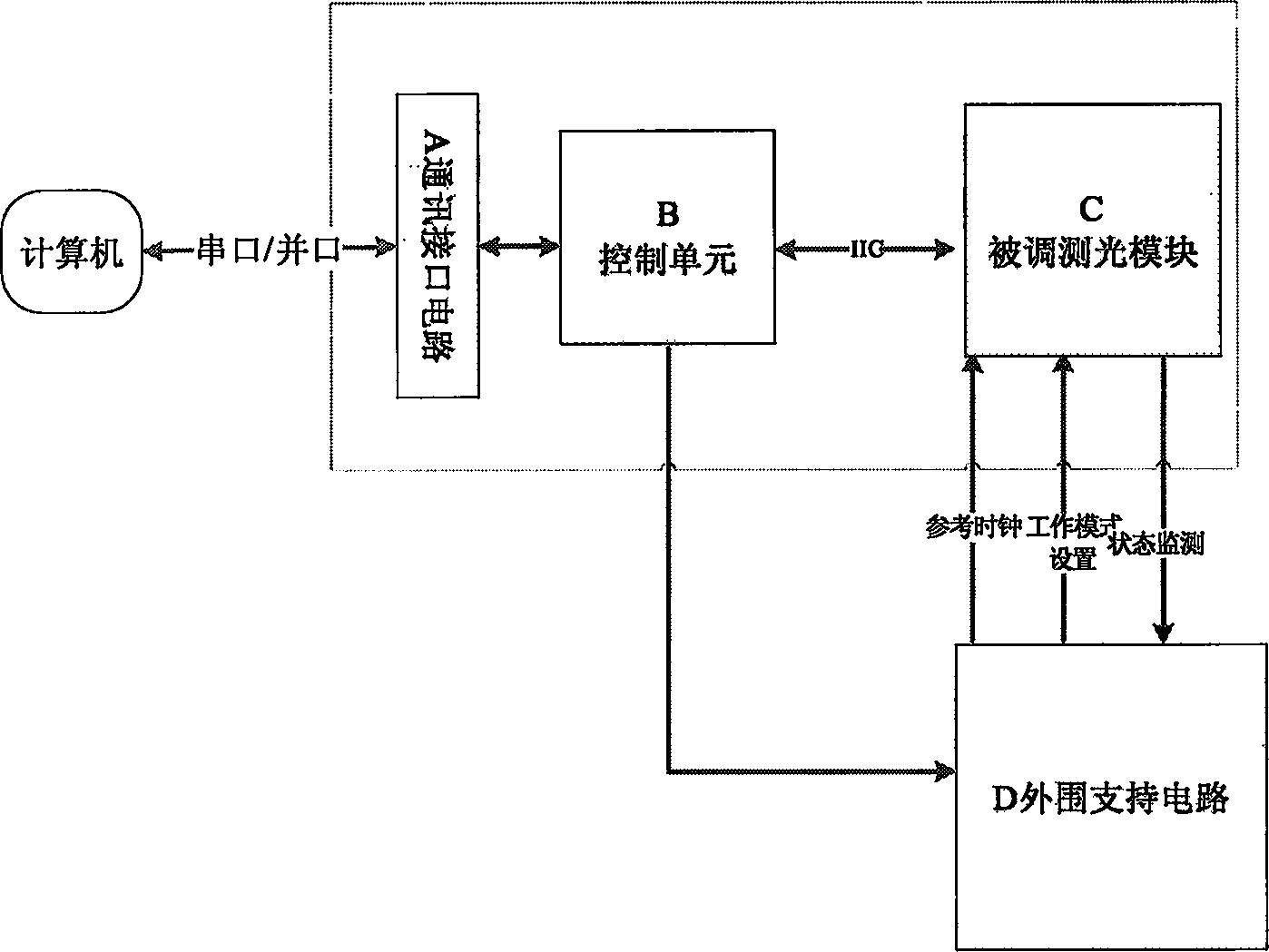

[0063] The basic components of the optical module commissioning device of the present invention include: a communication interface circuit and a control unit, such as figure 2 shown in A and B. The connection relationship between the optical module commissioning device and the computer and the optical module to be tested is as follows: figure 2 As shown, C in the figure is the optical module to be tested.

[0064] When commissioning the optical module, the operator sets the commissioning options through the commissioning interface on the computer and issues commissioning commands. The issued commissioning command is sent to A (communication interface circuit) through the serial port. The communication interface circuit converts the received signal into a signal that B (control unit) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com